-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

Diamond Core Drill Bit: Your Ultimate Guide to Understanding and Using This Essential Tool

- Knowledge, PCD & CBN Tools Knowledge

- -2025-04-02

- - byKevin Ray

Do you have any needs for PCD tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Post Categories

Product Categories

About Company

Table of Contents

A diamond core drill bit is a specialized cutting tool designed to create precise, circular holes in hard materials like concrete, stone, glass, and ceramics, using a hollow, tubular design with diamond-impregnated edges that grind through surfaces efficiently. Its unique construction and diamond strength make it ideal for professional and DIY projects requiring clean, accurate results. Unlike traditional drill bits, it removes a core of material, operates with high-speed rotation, and often uses water to cool the bit, ensuring durability and performance across diverse applications, from construction to delicate crafting.

What is a Diamond Core Drill Bit and How Does It Work?

Definition and Basic Functionality

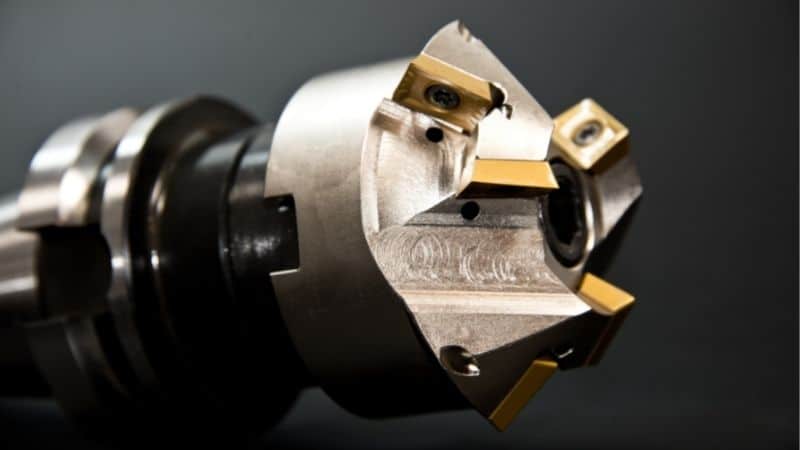

A diamond core drill bit is built to drill perfect, round holes in hard materials that other tools struggle to penetrate. It consists of a steel tube with a cutting edge embedded with tiny, durable diamonds, secured in a metal matrix. These diamonds grind through tough surfaces like concrete or glass without breaking.

The process begins by attaching the bit to a drill that spins it at high speed. When pressed against the material, the diamonds gradually grind away a circular section. The hollow center allows the cut material—known as the core—to remain inside, which can be removed later. Water or coolant is often applied to prevent overheating, extending the bit’s life and maintaining a clean cut. For instance, builders use these bits to drill through concrete walls for plumbing, achieving better results than standard bits without cracking the surface.

Key Features and Benefits

Diamond core drill bits offer distinct advantages that set them apart:

- Durability: The diamond-impregnated edge ensures long-lasting cutting power.

- Versatility: They excel on concrete, stone, glass, and tiles.

- Precision: They produce smooth, accurate holes with minimal cleanup.

- Efficiency: Fast cutting speeds save time on large projects.

- Material-Friendly: Grinding rather than breaking reduces damage to the surface.

These features are critical in practical applications. For example, when installing pipes through a concrete floor, a diamond core drill bit delivers a clean, quick hole for a perfect fit. Tool manufacturers report that diamond bits can drill through reinforced concrete—containing metal bars—at speeds up to 1 inch per minute, depending on the drill and bit size. This efficiency minimizes mess and reduces the need for repairs, cutting costs on projects like wiring or anchoring in construction.

Why Choose a Diamond Core Drill Bit Over Other Types?

Advantages in Different Materials

Diamond core drill bits excel across a range of hard materials, making them a top choice for various tasks:

- Concrete: They cut smoothly through concrete, even with embedded rebar. Builders rely on them for pipe holes in walls, where regular bits often fail.

- Stone and Rock: Perfect for granite or marble, they avoid chipping, ensuring neat holes for projects like countertops.

- Glass and Ceramics: Their precision prevents shattering, making them ideal for jewelers crafting glass beads.

- Tiles: They cut bathroom or kitchen tiles cleanly, preserving a professional finish.

The diamond’s hardness and the bit’s cooling design enable this versatility. Some diamond bits can achieve speeds up to 1.5 inches per minute in reinforced concrete, far outpacing carbide bits, which may take twice as long.

Cost-Effectiveness and Longevity

Diamond bits justify their higher initial cost through long-term savings:

- Longevity: A single diamond bit might drill 50 holes in concrete, compared to 10 with a carbide bit.

- Time Savings: Faster, smoother cuts reduce labor hours.

- Reduced Cleanup: Clean holes eliminate extra finishing work.

- Versatility: One bit handles multiple materials, reducing tool expenses.

Consider this cost comparison:

| Bit Type | Cost | Holes Drilled | Cost per Hole |

|---|---|---|---|

| Carbide Bit | $20 | 10 | $2.00 |

| Diamond Bit | $100 | 50 | $2.00 |

While a $20 carbide bit seems cheaper, drilling 50 holes requires five carbide bits ($100 total), matching the cost of one diamond bit. The diamond bit’s speed and quality, plus fewer replacements, amplify savings on large-scale projects like plumbing installations.

How to Select the Right Diamond Core Drill Bit for Your Project?

Understanding Different Types and Specifications

To choose the best diamond core drill bit, match its type and features to your job’s material and size needs. Options include wet bits, which use water for cooling during concrete drilling, and dry bits, suited for softer materials like brick. The bond type—the metal matrix holding the diamonds—varies: soft bonds suit hard materials like glass, while hard bonds tackle softer concrete. Segment styles also differ—turbo segments speed up concrete jobs, while crown segments ensure smooth glass cuts.

Sizes range from 1mm for small holes to over 60mm for construction, with lengths up to 14 inches for deep drilling. Manufacturers offer bits for specific tasks, like a 10mm wet bit for tiles or a 50mm bit for walls. Assess your material, hole size, and depth to select the right bit.

Matching Drill Bit to Material and Project Needs

Align the bit’s features with your project’s specifics. For concrete, use a hard-bond, wet bit; for glass, a soft-bond, wet bit prevents cracks. Stone varies—soft limestone needs a harder bond, while granite requires a medium one. Hole size and depth dictate bit dimensions: a 5mm bit suits tile, while a 50mm bit fits concrete pipes. Match the bit to your drill—handheld for small tasks, rig-mounted for large ones.

Here’s a guide:

| Material | Bond Type | Wet or Dry | Segment Style |

|---|---|---|---|

| Concrete | Hard | Wet | Turbo |

| Glass | Soft | Wet | Crown |

| Granite (Stone) | Medium | Wet | Segmented |

| Brick | Hard | Dry | Turbo |

Ensure your drill’s power supports the bit size. Manufacturers provide tailored options, so consult their guides for the best match.

What are the Best Practices for Using a Diamond Core Drill Bit?

Preparation and Safety Measures

Proper preparation ensures safety and success with diamond core drill bits. Wear safety goggles, work gloves, a dust mask, and ear protection to guard against debris and noise. Inspect the bit and drill for damage, and secure the material with clamps to prevent movement. Stand on a stable surface, and follow supplier guidelines, such as using water for cooling, to avoid issues like overheating.

Step-by-Step Usage Guide

Follow these steps for effective drilling:

- Attach the bit: Secure it tightly to the drill.

- Mark your spot: Outline the hole’s location.

- Add water if needed: Cool the bit during tough cuts.

- Start slow: Begin at low speed to establish the cut.

- Speed up carefully: Increase speed with steady pressure.

- Monitor progress: Adjust speed or water if dust or smoke appears.

- Finish up: Remove the bit and extract the core.

- Clean the hole: Clear debris for a polished result.

A plumber drilling concrete floors for pipes uses this method, starting slow to preserve the bit’s integrity.

Maintenance and Care Tips

Extend your bit’s life with these practices:

- Clean after use: Remove dust or rinse off water residue.

- Store properly: Keep it in a dry, protective case.

- Inspect regularly: Check for diamond wear.

- Replace when dull: Swap it out if cutting falters.

A cared-for bit can drill up to 50 concrete holes, compared to 10 for a neglected one, saving significant costs.

How Can You Troubleshoot Common Issues with Diamond Core Drill Bits?

Identifying and Solving Performance Problems

Address these common issues to maintain performance:

- Slow Cutting: Use the right bit for the material, check for dullness, and apply more pressure.

- Overheating: Add water and reduce speed (e.g., 600-1200 RPM for concrete).

- Rough Holes: Stabilize the drill and adjust speed (e.g., 800 RPM for concrete).

- Bit Slipping: Start with a pilot hole or use tape for grip.

Here’s a summary:

| Problem | Why It Happens | How to Fix It |

|---|---|---|

| Slow cutting | Wrong bit, dull, low pressure | Match bit, check wear, press harder |

| Overheating | No water, too fast | Use water, lower speed |

| Rough holes | Wobbling, wrong speed | Steady drill, adjust speed |

| Bit slipping | No pilot, smooth surface | Make pilot hole, use tape |

When to Replace Your Drill Bit

Replace the bit when the diamonds appear flat, cracks form, or performance drops despite troubleshooting. Inspect it under light—if the edge isn’t gritty, it’s worn. A well-maintained bit lasts for 50 concrete holes, while a neglected one fails after 10, so timely replacement ensures quality results.

Concluding Summary

Diamond core drill bits are indispensable tools for professionals and DIY enthusiasts alike, offering unmatched precision and durability when drilling through tough materials like concrete, stone, glass, and ceramics. This guide has covered their functionality, selection, usage, and troubleshooting, emphasizing best practices like preparation, technique, and maintenance. Mastering these tools ensures efficient, professional-grade outcomes, saving time and money across diverse projects.

ZY Superhard Tools Co., Ltd.

Do you have any needs for PCD tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Do you have any needs for PCD tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Related Posts

All You Need To Know About Polycrystalline Diamond (PCD) Tools

Discover Polycrystalline Diamond (PCD) tools: their definition, manufacturing process, unique characteristics, industrial applications, and expert tips for selection and maintenance.

What Are PCD Inserts Used For?

Discover what PCD inserts are used for, including ideal materials like aluminum and composites, key advantages, and industries like automotive

What Is Edge Radiusing for PCBN Inserts and Why Does It Matter for Machining?

Learn about edge radiusing for PCBN inserts, its methods, quality factors, performance impact, measurement, and optimization tips for better machining.

What Are Diamond Grinding Wheels and Why Should You Care?

Discover what diamond grinding wheels are, their types, uses, and benefits. Learn how they enhance precision and efficiency in grinding

Subscribe

Simply enter your email below and click “Subscribe” to stay connected with everything new and exciting.