-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

The Importance of Tool Dynamic Balance: A Complete Guide

- Industry Knowledge, Knowledge

- -2025-07-12

- - byKevin Ray

So, what makes a tool’s state of dynamic balance so critical for modern industry?

A tool’s proper dynamic balance is a crucial property that ensures the smooth operation of machinery. Achieving this state is a fundamental engineering practice, vital for maximizing equipment performance and lifespan, ensuring product quality, lowering costs, and guaranteeing operational safety.

Table of Contents

ToggleUnderstanding Dynamic Balance: What It Is and Why It Matters

Ever wondered why some machines run with a smooth, quiet hum while others vibrate violently?

Dynamic balancing is a precise process used to correct the uneven distribution of weight in a rotating object, such as a tool, spindle, or fan. It is essential because it eliminates vibration at the source, which in turn prevents premature component failure, improves operational performance, and ensures the safety and quality of the final product.

Defining Dynamic Balance: Ensuring Smooth Rotation

Imagine a spinning top. When its weight is perfectly centered, it spins smoothly and elegantly. But what happens if you stick a tiny piece of clay to one side? It immediately starts to wobble and will quickly fall over. This wobble is caused by an imbalance.

In the world of machinery, every rotating component, from a massive industrial fan to a tiny dental drill, has a centerline that it’s supposed to spin around. This is its axis of rotation. It also has a center of mass, or a mass centerline. In a perfect world, these two lines would be exactly the same.

However, due to tiny imperfections in manufacturing or material, they rarely are.

Dynamic balancing is the technical process of measuring this imbalance while the part is spinning and then making precise adjustments to bring the mass centerline perfectly in line with the axis of rotation. This is usually done by either adding small weights to the light side or removing a tiny amount of material from the heavy side. The goal is to make the tool or component spin as if it were perfectly uniform, thereby eliminating the forces that cause vibration.

Balance Quality and Tolerances

How much balance is “good enough”? This isn’t a one-size-fits-all answer. The required precision is defined by international standards, such as those in ISO 21940, which provides balance quality grades (G-grades) for different types of rotating machinery.

For instance:

- A rugged crusher part might be acceptable with a G40 grade.

- A standard electric motor rotor might require a G6.3 or G2.5.

- A high-speed CNC machine tool spindle may demand a G1.0 or even a G0.4 grade for ultimate precision.

These G-grades specify the maximum permissible residual unbalance at the service speed. Because these tolerance requirements can vary based on the specific application and manufacturer specifications, it’s always wise to verify the exact balance grade required for your equipment with the supplier or manufacturer.

Contrasting Static and Dynamic Balance: Understanding the Difference

While they sound similar, achieving a state of static balance versus dynamic balance are fundamentally different concepts. Understanding this difference is key to appreciating why a high degree of dynamic balance is so crucial for most modern machinery. Static balance is a good first step, but it only tells part of the story.

| Feature | Static Balance | Dynamic Balance |

|---|---|---|

| Condition of Test | The tool or part is at rest (not spinning). | The tool or part is in motion (spinning at speed). |

| Forces Corrected | Corrects for “static” imbalance, where a heavy spot causes the part to roll to the bottom due to gravity. | Corrects for both static imbalance and “couple” imbalance, a wobbling force that only appears during rotation. |

| Typical Application | Best for thin, disc-like objects where the length is very small compared to the diameter, like a slow-moving pulley or a flywheel. | Essential for any part that is long relative to its diameter or rotates at high speeds, such as CNC spindles, drive shafts, and turbine rotors. |

| Correction Method | Can often be corrected by adding a single weight opposite the heavy spot. | Requires correction in at least two separate planes along the part’s length to counteract the wobbling effect. |

Think of it this way: achieving static balance is like trying to balance a car tire by just letting it settle with the heavy spot down. Achieving dynamic balance is what a professional tire shop does, spinning the tire on a machine to find and correct imbalances that would only cause a shake at highway speeds. For any high-performance or high-speed tool, ensuring dynamic balance isn’t just an option—it’s a necessity.

The Key Benefits of Proper Tool Dynamic Balance

So, what are the real-world advantages of ensuring a tool has proper dynamic balance?

Proper tool dynamic balance provides critical, measurable benefits that go far beyond simple vibration reduction. These key advantages include significantly enhanced equipment performance and efficiency, a much longer operational lifespan for tools and machinery, superior product quality and precision, dramatically lower maintenance costs and downtime, and a fundamentally safer working environment.

How Proper Tool Balance Enhances Equipment Performance and Efficiency

Think about the energy it takes to shake a heavy object. That is precisely what an unbalanced tool forces a machine to do—waste energy by shaking itself. This wasted motion serves no productive purpose and reduces the machine’s overall performance.

When a tool or rotor is in a state of dynamic balance, that wasted vibrational energy is eliminated. Consequently, nearly all the input power is converted directly into useful work, whether it’s cutting material, moving air, or grinding a surface.

An industrial fan with unbalanced blades, for example, forces the motor to fight against its own wobble, consuming more electricity to reach and maintain its target RPM. A balanced fan, in contrast, runs smoothly, allowing it to move the same amount of air with less energy consumption. This leads directly to lower power bills and improved operational efficiency.

Why a Tool Dynamic Balance Significantly Extends Machine Lifespan

Vibration is a machine’s worst enemy. It acts like a series of tiny, relentless hammer blows on every component. The primary victims of this constant assault are the bearings. An unbalanced state creates cyclic loads that far exceed what the bearings are designed for, leading to rapid wear and premature failure.

Consider this widely accepted industry principle: reducing vibration by just 50% can extend the life of a roller bearing by up to eight times.

But it doesn’t stop at the bearings. This constant shaking also causes structural fatigue in machine frames, welds, and mounting bolts. It can even lead to electrical connectors working themselves loose. By ensuring a tool’s dynamic balance, you remove the root cause of vibration and protect every single part of the machine, significantly extending its service life and reliability.

How Proper Tool Balance Reduces Vibration and Noise Levels

This is the most direct and noticeable benefit. The relationship is simple: an unbalanced state causes vibration, and vibration creates noise.

Imagine a large, unbalanced rotor spinning at thousands of revolutions per minute. The entire machine structure is forced to shake, and these vibrations travel through the floor and into the air as audible sound waves. The result is a loud, often irritating, and sometimes dangerously noisy work environment.

Ensuring proper tool balance attacks the problem at its source. With the unbalanced forces eliminated, the machine runs smoothly and quietly. This not only creates a more pleasant workplace but also helps facilities comply with occupational health standards, such as those set by OSHA1 regarding permissible noise exposure levels.

How a Tool Dynamic Balance Contributes to Improved Product Quality and Precision

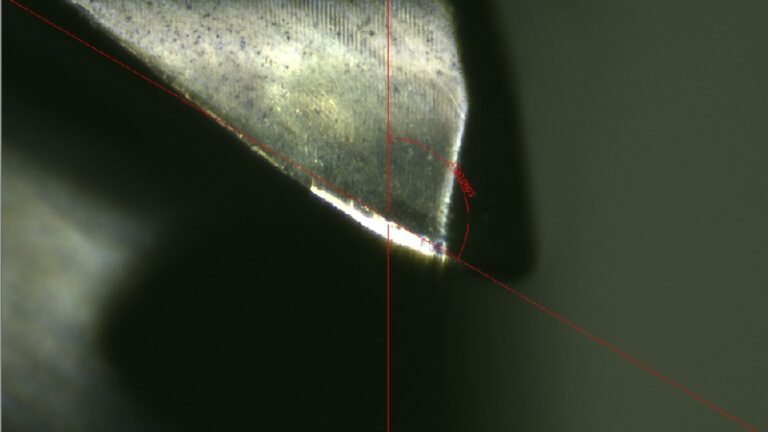

In any manufacturing process where precision is key, vibration is unacceptable. This is especially true in the machining industry.

Let’s look at a CNC milling machine. A tool holder or spindle with poor balance will vibrate as it cuts into a workpiece. This vibration transfers to the cutting edge, resulting in:

- Poor Surface Finish: Instead of a smooth, clean surface, the part will have visible “chatter” marks.

- Inaccurate Dimensions: The vibration makes it impossible to hold tight tolerances, leading to parts that are out of specification.

- Reduced Tool Life: The constant impact from vibration can chip or dull the cutting tool’s edge much faster than normal.

By ensuring the entire rotating assembly has a high-precision dynamic balance grade (e.g., G2.5 or G1.0), manufacturers can achieve a flawless surface finish, maintain dimensional accuracy, and get the maximum life out of their expensive cutting tools2.

What Impact Does Proper Tool Balance Have on Reducing Downtime and Maintenance Costs?

Unplanned downtime is one of the biggest hidden costs in any industrial operation. Every minute a production line is stopped for an unexpected repair, money is lost. Since an imbalanced state is a leading cause of mechanical failure, it’s also a primary driver of downtime.

The financial equation is straightforward:

- An Imbalanced State leads to…

- Vibration and Stress, which causes…

- Premature Bearing and Component Failure, resulting in…

- Unplanned Machine Downtime and…

- Costly Emergency Repairs.

Ensuring proper dynamic balance is a proactive maintenance strategy. By investing a small amount in the balance quality of a component, you prevent the cascade of failures that follows. This translates directly into fewer breakdowns, less need for replacement parts, and more predictable production schedules, ultimately slashing overall maintenance expenditures3.

Why is Proper Tool Balance Essential for Operational Safety?

This is arguably the most important benefit of all. In certain applications, an unbalanced component is not just a maintenance issue—it’s a catastrophic safety hazard.

Consider a large industrial grinding wheel4 or a heavy-duty ventilation fan spinning at high speed with poor balance. The forces generated by an imbalance increase with the square of the speed. This means that doubling the speed quadruples the unbalanced force. If this force exceeds the structural integrity of the rotor or its housing, the result can be an explosive failure.

A grinding wheel can shatter, or a fan blade can detach, sending heavy metal fragments flying through the workshop at lethal speeds. A high state of dynamic balance is a fundamental engineering control that prevents these catastrophic events, protecting not only the equipment but, more importantly, the lives of personnel in the area.

Diagnosing and Correcting Imbalance: A Practical Guide

So, how can you identify if poor tool balance is the root cause of your machinery problems, and what are the practical steps to resolve it?

An imbalance can be diagnosed through observable signs like vibration and noise, or definitively confirmed with specialized analysis equipment. The solutions involve a precise correction process, which can be performed either on-site (“field balancing”) for large machinery or in a specialized facility (“workshop balancing”) for individual components.

Identifying the Telltale Signs of an Imbalanced State

Before you can solve the problem, you must first recognize its symptoms. A component with poor dynamic balance will send out several clear distress signals.

Sensory and Physical Evidence

This is what your own senses and inspections can reveal directly on the shop floor:

- Visible Vibration or Chatter: The machine itself or its safety guards may be visibly shaking or rattling during operation.

- A Change in Sound: You might notice a new, low-frequency hum or a rumbling noise that wasn’t there before.

- Structural Stress Fractures: Over time, chronic vibration can cause fatigue cracks to appear in welds, mounting brackets, or even the machine’s foundation.

- Recurring Component Failure: If the same machine is consistently wearing out bearings, seals, or motor couplings prematurely, a persistent imbalance is the most likely culprit.

Definitive Technical Diagnosis

For a precise diagnosis, professionals use portable vibration analysis equipment. This involves placing small sensors (accelerometers) on the machine’s bearing housings to measure the exact signature of the vibration.

An imbalanced state has a unique fingerprint: a strong vibration spike that occurs at a frequency exactly matching the rotational speed of the component (known as 1x vibration). This measurement provides irrefutable proof of an imbalance issue and gives the technician the data (amplitude and phase) needed to plan a correction. When in doubt, it’s always best practice to consult the original equipment manufacturer’s (OEM) manual for acceptable vibration limits.

Understanding the Correction Process

Once an imbalance is confirmed, the solution is a precise, methodical correction. The goal is to counteract the component’s “heavy spot” by adding or removing a specific amount of mass at a specific location.

Based on the data from the vibration analyzer, specialized software calculates the exact correction needed. The two primary methods are:

- Additive Balancing: This involves adding weight. This is very common for components like industrial fan blades, where small, precisely measured metal weights are welded or bolted onto the lighter side of the component.

- Subtractive Balancing: This involves removing weight. This method is often used for solid, uniform components like motor rotors or machine spindles. The correction is made by drilling small, shallow holes or by lightly grinding material away from the identified heavy spot.

The best method depends on the component’s design, its material, and the accessibility for making permanent corrections.

Choosing the Right Solution: Field vs. Workshop Balancing

A crucial decision for any maintenance manager is where to perform the balancing. Each approach has distinct advantages and is suited for different situations.

| Factor | Field Balancing (On-Site) | Workshop Balancing (Off-Site) |

|---|---|---|

| Location | The correction process is performed on the component while it is fully installed and running in its own machine. | The component (e.g., a motor rotor, a roller) is removed from the machine and sent to a specialized facility with high-precision balancing machines. |

| Best For… | Large, hard-to-move machinery like industrial fans, large pumps, and heavy rollers. It’s also ideal for balancing the entire rotating assembly as a complete system. | New components before installation, high-precision tool assemblies (like CNC spindles and tool holders), and smaller components like electric motor armatures. |

| Downtime | Minimal. The machine is only out of service for the duration of the analysis and correction procedure itself. | Significant. The machine is down during the entire process of disassembly, transportation, balancing, and reassembly. |

| Precision | Highly effective for bringing most industrial equipment back within acceptable operating tolerances. | Highest possible precision. A dedicated workshop machine provides a controlled environment to achieve extremely fine balance grades (G1.0 or better). |

| Cost-Effectiveness | Often more cost-effective for large assets, as it avoids the immense labor and downtime costs associated with disassembly. | Justified when the highest degree of precision is non-negotiable for product quality or for components that rotate at extremely high speeds. |

Conclusion

Ultimately, a tool’s dynamic balance is not just a technical specification; it is a fundamental pillar of modern engineering and proactive maintenance. From extending the lifespan of critical bearings to ensuring the micron-level accuracy of a machined part, its benefits are woven into the fabric of nearly every industry. By understanding what constitutes good balance, why it’s crucial, where it’s applied, and how to correct for imbalance, you can move from a reactive state of fixing what’s broken to a proactive strategy of optimizing performance. Investing in the dynamic balance of your tooling is an investment in efficiency, quality, reliability, and most importantly, safety.

References

- OSHA1 – The official Occupational Safety and Health Administration (OSHA) topic page on occupational noise exposure standards and regulations.

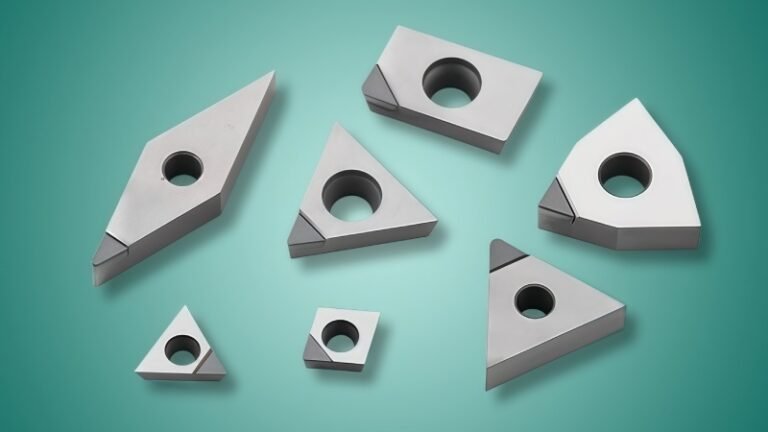

- Cutting Tools2 – A product category page from ZYDiamondTools showcasing various PCD & PCBN cutting tools.

- Expenditures3 – A guide from ZYDiamondTools on understanding the Total Cost of Ownership (TCO), which includes maintenance expenditures.

- Grinding Wheel4 – A product category page from ZYDiamondTools displaying a range of diamond and CBN grinding wheels.

ZY Superhard Tools Co., Ltd.

Do you have any needs for PCD tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Do you have any needs for PCD & CBN tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Do you have any needs for PCD & CBN tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Post Categories

Product Categories

About Company

Related Posts

Which Turning Insert Shape Should You Choose?

Master turning insert selection. Our guide covers choosing the right shape for your job, decoding ISO codes, and selecting the

How Do You Solve Vibration, Chip Control, and Surface Finish Issues in PCD Grooving?

Solve common PCD grooving problems. This guide details how to fix vibration, improve chip evacuation, and achieve a flawless sidewall

Why Is Your Tooling Wearing Out Prematurely? A Machinist’s Guide to Key Causes & Proven Solutions

Facing premature tool wear? Learn the key causes like heat, vibration, & wrong parameters. Discover proven solutions from setup to

How Do You Select the Optimal PCD Tools for Scroll Compressor Machining?

Learn how to select the right PCD tools for scroll compressor machining. This guide covers the benefits over carbide, key

Subscribe

Simply enter your email below and click “Subscribe” to stay connected with everything new and exciting.