-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

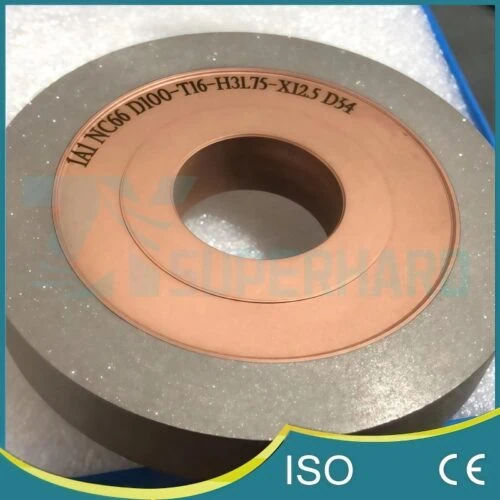

Vitrified Bond Diamond Grinding Wheels For PCD Tools Grinding

Precision vitrified diamond wheels for grinding PCD, PCBN, CVD tools. Offer fine micron grits (W3.5-W50) for sharp edges & high accuracy on EWAG, Coborn, Anca grinders. Custom specs.

Vitrified Bond Diamond Grinding Wheels for PCD/PCBN Tool Grinding

Achieve superior cutting edge quality and precision when manufacturing or re-sharpening Polycrystalline Diamond (PCD), Polycrystalline Cubic Boron Nitride (PCBN), CVD Diamond, and other super-hard cutting tool materials with these advanced Vitrified Bond Diamond Grinding Wheels from ZYsuperhard. Specifically engineered for use on high-precision tool grinding machines, they provide the optimal combination of efficient material removal, excellent surface finish, and dimensional accuracy.

The Vitrified Bond Advantage for Grinding Superhard Tools

Vitrified (ceramic) bonds offer a unique set of properties ideal for the demanding task of grinding ultra-hard, often brittle, cutting tool materials:

- Controlled Porosity for Cool Cutting: The inherent porous structure of the vitrified bond allows for excellent coolant penetration directly into the grinding zone and facilitates efficient chip removal. This minimizes thermal damage to heat-sensitive materials like PCD and prevents wheel loading.

- High Rigidity and Form Holding: Vitrified bonds provide excellent stiffness and resistance to deformation under load, ensuring the wheel maintains its precise profile and geometric accuracy throughout the grinding process, critical for achieving tight tolerances on tool edges.

- Optimal Balance of Wear and Self-Sharpening: Engineered for a controlled wear rate that continuously exposes fresh, sharp diamond particles, providing consistent grinding performance and high material removal efficiency relative to the fine finishes required.

Diamond Abrasive and Fine Micron Grits for Ultimate Precision

- Diamond is Essential: Diamond remains the only effective abrasive for efficiently grinding PCD, PCBN, CVD, natural diamond, technical ceramics, and cemented carbides due to its unmatched hardness.

- Fine Micron Grit Sizes (W-Series): To achieve the extremely sharp, defect-free cutting edges and low surface roughness(Ra) required for high-performance superhard tools, these wheels utilize fine diamond particles specified in Micron grades (e.g., W50 down to W3.5). This corresponds approximately to FEPA F ~230 grit down to F ~4000 grit or even finer, enabling processes from fine grinding to near-polishing of the tool edge.

Application Focus: Manufacturing & Re-Sharpening Superhard Cutting Tools

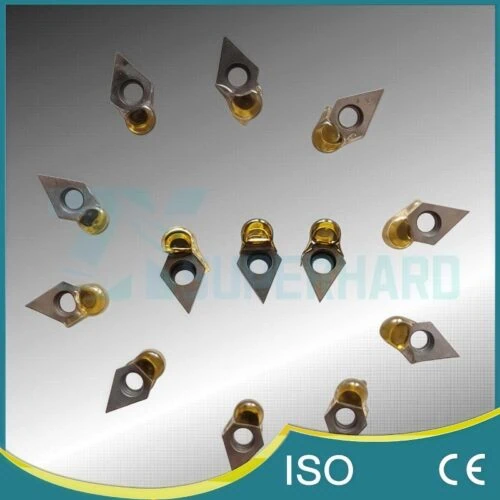

These specialized wheels are the industry choice for critical grinding operations on:

- PCD / PDC Tools: Manufacturing and re-grinding tools used in woodworking, automotive (aluminum machining), aerospace (composites), and more.

- PCBN Tools: Precision grinding of PCBN inserts and tools used for machining hardened steels, cast irons, and superalloys.

- CVD Diamond Tools: Processing tools coated with or made from CVD diamond.

- Natural Single Crystal Diamond Tools: Shaping and sharpening natural diamond tools for ultra-precision applications.

- Technical Ceramics & Cemented Carbide: High-precision finishing of ceramic components or carbide tools/wear parts where diamond is the appropriate abrasive.

Machine Compatibility & Wheel Shapes

- Optimized for Tool Grinders: Designed for optimal performance on high-precision CNC tool grinding machines such as EWAG, Coborn, Anca, Walter, and similar equipment.

- Common & Custom Shapes: Frequently supplied in standard tool grinding shapes like 6A2 (Cup Wheel), but ZYsuperhard manufactures wheels in virtually any required shape or profile according to customer drawings (e.g., 1A1, 1V1, 11V9, etc.).

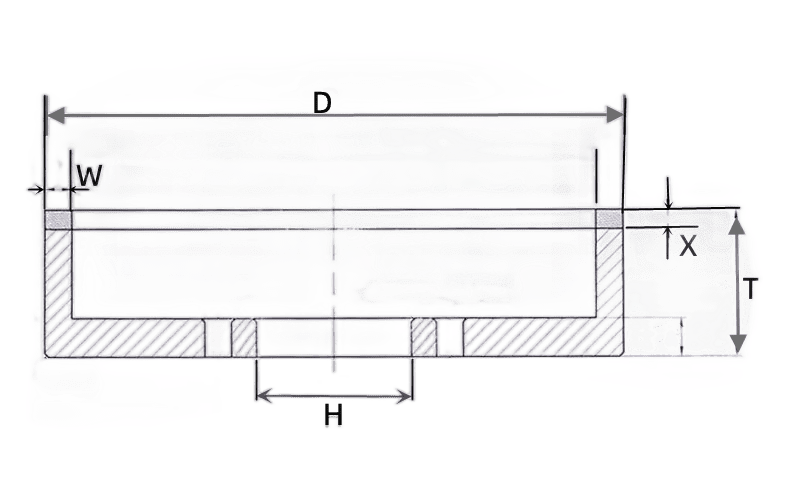

- Typical Specification Format: Wheels are specified using parameters typically in the order of: [Shape Code] D[Diameter] – H[Hole] – T[Thickness] – X[Rim Width] – W[Grit Size].

Tailored to Your Exact Grinding Requirements

We produce these vitrified diamond wheels as custom solutions:

- Specify Your Needs: Provide details on the material being ground (e.g., specific PCD/PCBN grade), the grinding operation (roughing, semi-finishing, finishing, polishing), target edge quality/finish, machine type, and the required wheel Grit Size (W3.5 to W50 or other), Diamond Concentration, Dimensions (D, T, H, X, E), Shape, and Bond Formulation.

Contact our superhard material grinding specialists today. Submit your application details or wheel drawing to receive a precisely engineered vitrified diamond grinding wheel solution designed for optimal performance and tool life.