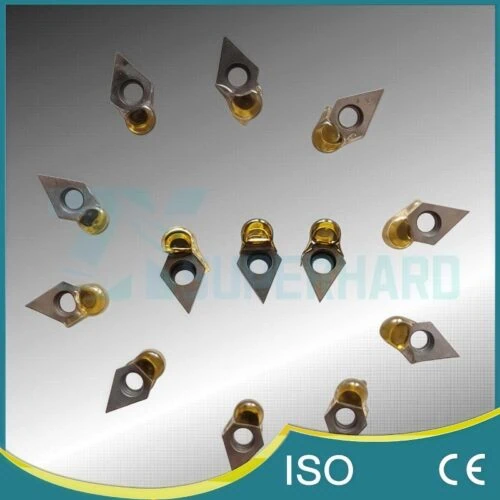

Thread Shank Diamond Drill Bits for Efficient Glass Drilling

Effortlessly drill clean, precise holes in a variety of glass materials with these robust Thread Shank Diamond Drill Bits from ZYsuperhard. Engineered with a durable sintered metal bond and optimized diamond grits, these core drill style bits offer exceptional longevity and reliable performance for glass fabricators, artisans, and industrial applications requiring high-quality holes in glass.

Engineered for Superior Glass Drilling Performance

These drill bits integrate key features designed specifically for the challenges of drilling glass:

- Durable Sintered Metal Bond: Utilizes a tough bronze-based metal bond matrix, created through a high-temperature sintering process. This yields an extremely wear-resistant and long-lasting cutting edge that effectively withstands the abrasive nature of glass, maximizing the tool’s operational life.

- High-Quality Diamond Abrasive: Employs carefully selected diamond grains within the versatile 40# to 120# grit size range. This allows users to balance drilling speed (using coarser grits like 40# for thicker glass or faster removal) with edge finish quality (using finer grits like 120# for thinner glass or reduced chipping).

- Secure Thread Shank Mounting: Features a threaded shank designed for secure and stable mounting onto compatible glass drilling machines, rotary tools, or drill presses equipped with the appropriate threaded adapter. This often provides superior concentricity and rigidity compared to standard chucked shanks, contributing to drilling accuracy and reducing vibration.

- Core Drill Design with Internal Cooling Potential: The hollow core design not only allows for the removal of a glass slug (when drilling through) but critically enables efficient coolant delivery directly through the center to the cutting zone. Consistent cooling is vital when drilling glass to prevent heat buildup, thermal shock, and cracking.

Exceptional Lifespan and Drilling Precision

- High Hole Count Potential: When used under optimal conditions – appropriate speed, moderate pressure, and constant lubrication/coolant (water is recommended) – each ZYsuperhard diamond drill bit demonstrates the potential to produce 3,000 to over 7,000 holes, offering outstanding value and process efficiency.

- Precise and Clean Holes: Delivers accurately sized holes with cleaner, smoother edges compared to some alternative methods, minimizing the need for secondary finishing.

Versatile Glass Drilling Applications

Ideal for creating holes in a wide array of glass types:

- Sea Glass, Beach Glass, Tumbled Glass

- Fused Glass, Slumped Glass, Art Glass

- Sheet Glass, Plate Glass, Float Glass

- Glass Bottles, Jars (requires proper jigging and coolant)

- Stained Glass Panels

- (Note: Generally not recommended for drilling tempered safety glass due to its internal stresses.)

Maintaining Peak Performance: Dressing the Diamond Tip

Over time, the diamond particles can become dull or the metal bond can glaze over. To maintain sharp cutting action and expose fresh diamond edges:

- Recommendation: Periodically dress the diamond tip. This is easily done by briefly drilling into a soft, abrasive material like an aluminum oxide dressing stone.

- Mechanism: This action gently erodes a small amount of the metal bond, revealing new, sharp diamond cutting points and ensuring the drill bit continues to perform optimally. Regular light dressing after use is recommended.

Customization Options

We can manufacture these thread shank diamond drill bits to meet your specific requirements:

- Custom Specifications: Provide us with your desired drill diameter, drilling depth (core length), thread size specification, preferred diamond grit size (within or outside the 40-120# range), or other specific geometric features based on your drawings.

Contact our glass drilling application specialists today to discuss your needs and specify the ideal thread shank diamond drill bit configuration for your project.