-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

SPMG PCD Drilling Inserts

Replace carbide SPMG inserts with long-life PCD for drilling aluminum alloys. Ideal for high-precision applications in Automotive, Aerospace, and general machining.

Boost Aluminum Drilling Performance with Direct Replacement SPMG PCD Inserts

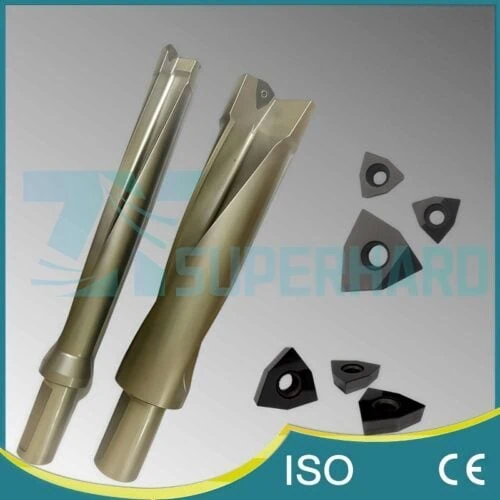

Upgrade your drilling operations in aluminum alloys with ZY SUPER HARD’s SPMG PCD Drilling Inserts. Specifically designed as a direct, high-performance replacement for standard carbide inserts like SPMG110408 DG, these premium tools leverage the power of Polycrystalline Diamond (PCD) to deliver dramatic improvements in tool life, operational efficiency, and hole quality. They are ideal for demanding Aerospace, Automotive, and high-volume general machining applications and are compatible with common tool holders such as the TDR 5390-32T2-11.

Key Features and Enhanced Benefits:

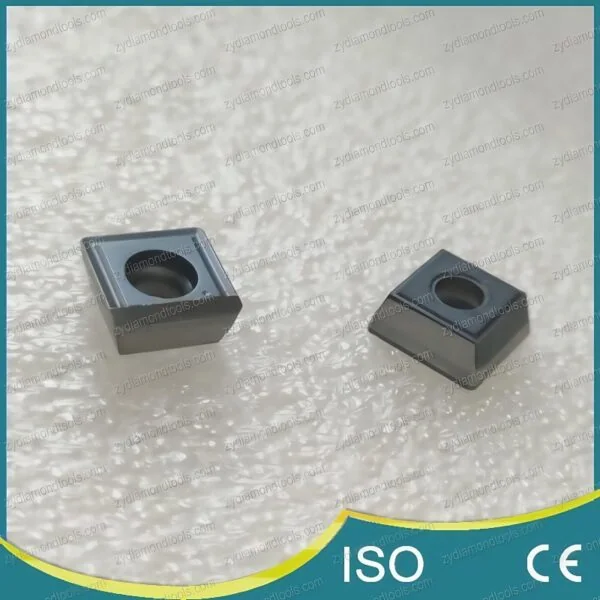

- Robust Single PCD Cutting Edge: Features a meticulously prepared single PCD cutting edge, engineered for exceptional durability and superior cutting efficiency in aluminum alloys. While conventional carbide SPMG inserts offer multiple indexes, the extreme wear resistance of this single PCD edge allows it to outlast multiple carbide edges combined. This significantly reduces machine downtime required for insert indexing or replacement, directly lowering your overall cost per hole.

- Massive Tool Life Extension: Expect a usable lifespan 50 to 100 times longer than that of standard carbide inserts when drilling various aluminum alloys (including silicon-containing grades). This massive increase translates directly into fewer insert purchases and substantial operational cost savings.

- Consistent High-Quality Holes: The inherent high hardness, strength, and thermal stability of the PCD edge ensure it maintains sharpness and geometric integrity for vastly extended periods. This results in highly consistent hole diameters, improved surface finish, reduced burr formation, and reliable dimensional accuracy throughout long production runs.

- Seamless Integration: Engineered with the exact dimensions of the SPMG110408 DG carbide insert and compatibility with standard holders like the TDR 5390-32T2-11, these PCD inserts enable a smooth and easy upgrade path, often without requiring investment in new tool bodies.

- Truly Cost-Effective Solution: Despite a potentially higher initial insert price compared to carbide, the vastly extended tool life per edge, coupled with significantly reduced machine downtime and improved part quality, makes these SPMG PCD inserts a highly cost-effective solution for high-production aluminum drilling environments.

Model: SPMG110408

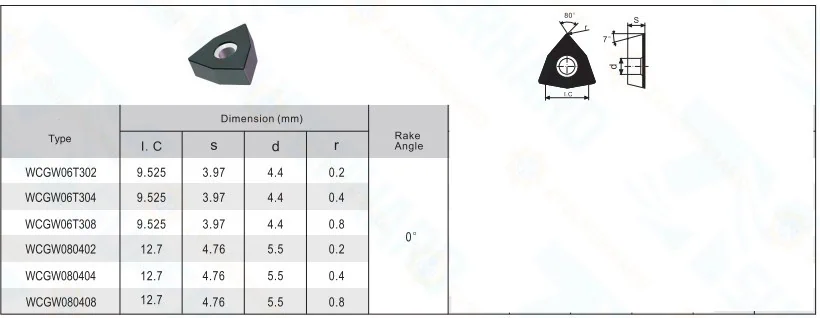

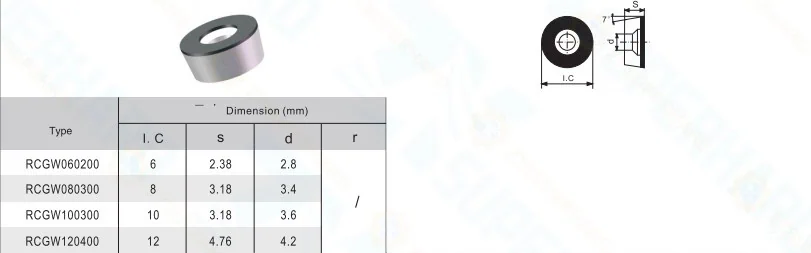

While the SPMG110408 replacement is a key product, ZY SUPER HARD also provides other PCD insert geometries, such as full face WCGW and RCGW inserts, to meet diverse application needs requiring different cutting approaches.

Upgrade to ZY SUPER HARD’s SPMG PCD Drilling Inserts today for unparalleled machining quality, extended longevity, and superior manufacturing economy. If you have specific requirements regarding edge preparations, PCD grades, or unique dimensions, contact us for customized tooling solutions!