-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

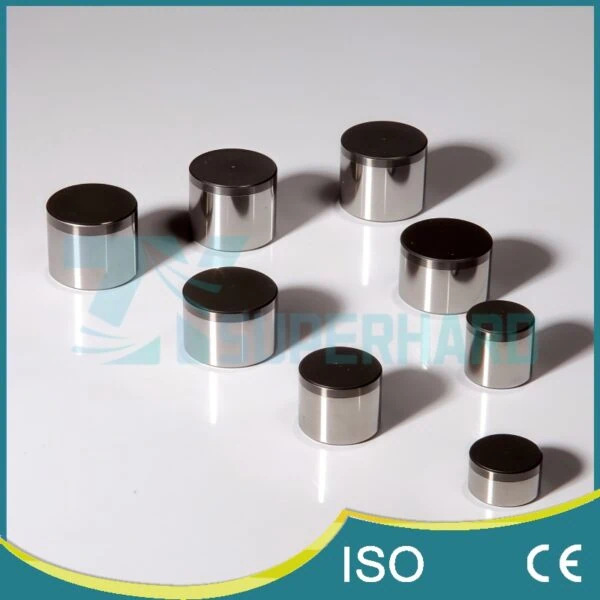

Polycrystalline Diamond Compact (PDC) Cutters

Engineered for excellence, our Polycrystalline Diamond Compact (PDC) cutters deliver unmatched wear resistance and superior impact strength. Dramatically increase drilling efficiency (ROP) and tool life in the most demanding oil, gas, and mining applications.

Premium Polycrystalline Diamond Compact (PDC) Cutters for Peak Drilling Performance

Discover the industry-leading solution for enhanced drilling operations with our premium Polycrystalline Diamond Compact (PDC) cutters. Manufactured using a state-of-the-art high-temperature/high-pressure (HTHP) sintering process, our PDC cutters fuse a micro-powder layer of polycrystalline diamond with a tough tungsten carbide substrate. This advanced composite structure creates a cutting tool that embodies the extreme hardness and abrasion resistance of diamond, perfectly balanced with the exceptional toughness and impact strength of tungsten carbide.

Our PDC cutters are the core components of modern PDC drill bits, designed to shear rock formations with unparalleled efficiency, leading to a significantly increased Rate of Penetration (ROP) and reduced overall drilling costs.

Key Features & Benefits:

- Unmatched Durability and Wear Resistance: The ultra-hard polycrystalline diamond layer provides a sharp, self-sharpening cutting edge that maintains its integrity even in highly abrasive formations, ensuring extended tool life and fewer bit trips.

- Superior Impact Strength: The robust tungsten carbide substrate acts as a resilient foundation, effectively absorbing and dissipating the high-impact forces encountered during drilling through challenging layers. This prevents chipping and catastrophic cutter failure.

- Enhanced Thermal Stability: Our specialized manufacturing process ensures high thermal stability, allowing the cutters to maintain their mechanical properties and cutting performance in high-temperature environments, such as deep well and geothermal drilling.

- Optimized for High ROP: The superior shearing action of our PDC cutters allows for faster and more efficient rock removal compared to conventional crushing or grinding methods, saving valuable time and operational expenses.

- Broad Application Versatility: Engineered for performance across a wide spectrum of drilling conditions, our PDC cutters excel in soft, medium, and hard rock formations. They are the ideal choice for manufacturers of drill bits used in:

- Oil and Gas Exploration and Production

- Mining and Mineral Exploration

- Geothermal Energy Drilling

- Water Well and Environmental Drilling

- Construction and Directional Boring

Technical Specifications (Sample):

We offer a comprehensive range of standard sizes and grades to meet diverse application needs. Below are some of our most common specifications. Please note that all dimensions and features can be customized.

| Model No. | Diameter (D) | Diamond Thickness | Carbide Thickness | Total Height (H) |

|---|---|---|---|---|

| 1308 | 13.44 mm | 2.0 mm | 6.0 mm | 8.0 mm |

| 1613 | 16.00 mm | 2.2 mm | 10.8 mm | 13.0 mm |

| 1916 | 19.05 mm | 2.5 mm | 13.5 mm | 16.0 mm |

(Note: The above specifications are examples. We provide a full range of sizes and can produce any custom dimension required.)

Custom Solutions for Your Unique Needs

We understand that standard solutions don’t fit every challenge. Our experienced engineering team is ready to partner with you to develop and manufacture custom PDC cutters tailored to your specific requirements. We offer customization options including, but not limited to:

- Custom Geometries (Diameter, Height, Shape)

- Variable Diamond Layer Thickness

- Non-Planar Interface Designs for enhanced stress distribution

- Specialized Chamfers and Edge Preparations

- Performance characteristics optimized for specific rock formations

Contact our technical sales team today to discuss your project. We are committed to providing you with high-performance PDC cutting blanks that will give your downhole tools a decisive competitive edge.