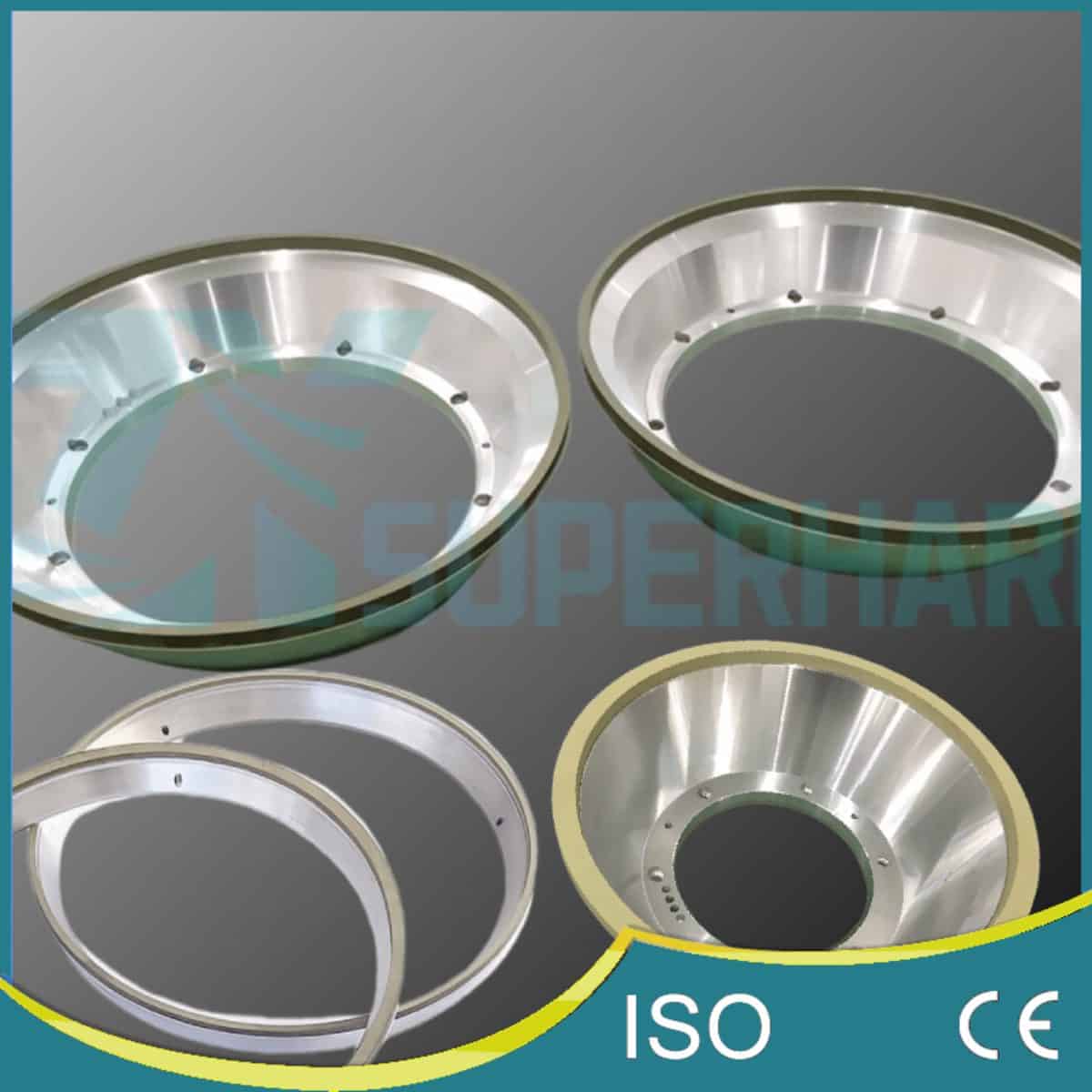

Vitrified Bond Diamond Periphery Grinding Wheels

We supply Resin and Vitrified bond diamond /CBN periphery grinding wheels

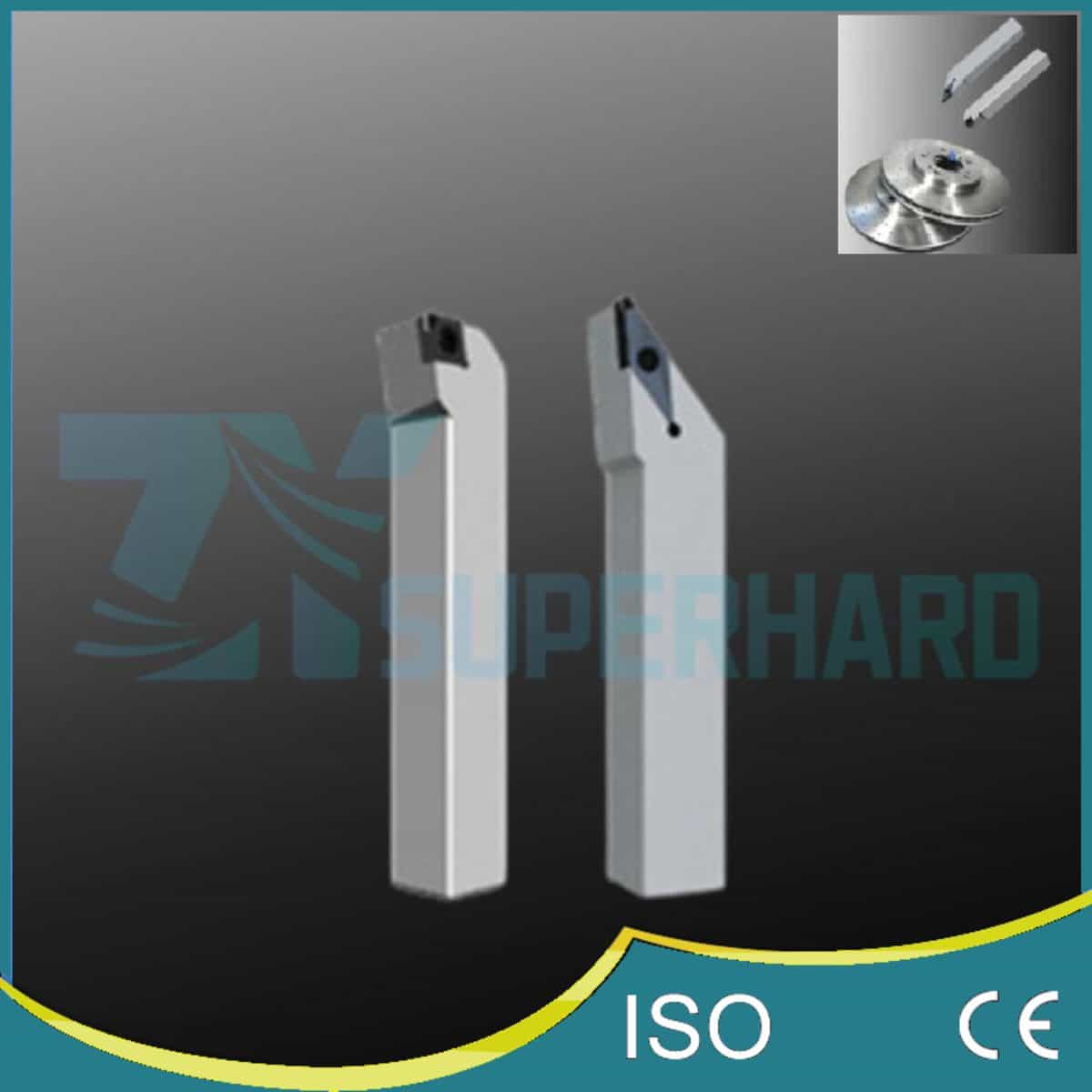

1. Application: It is mainly used for the precision edging of indexable inserts such as hard alloy, ceramic, PCD, and CBN inserts.

2.Model:11A2B,12A2T,6A2M,6A2T

3. Matched grinding machines: such as AGATHON, WAIDA, WENDT, EWAG, TDG-MT, etc.

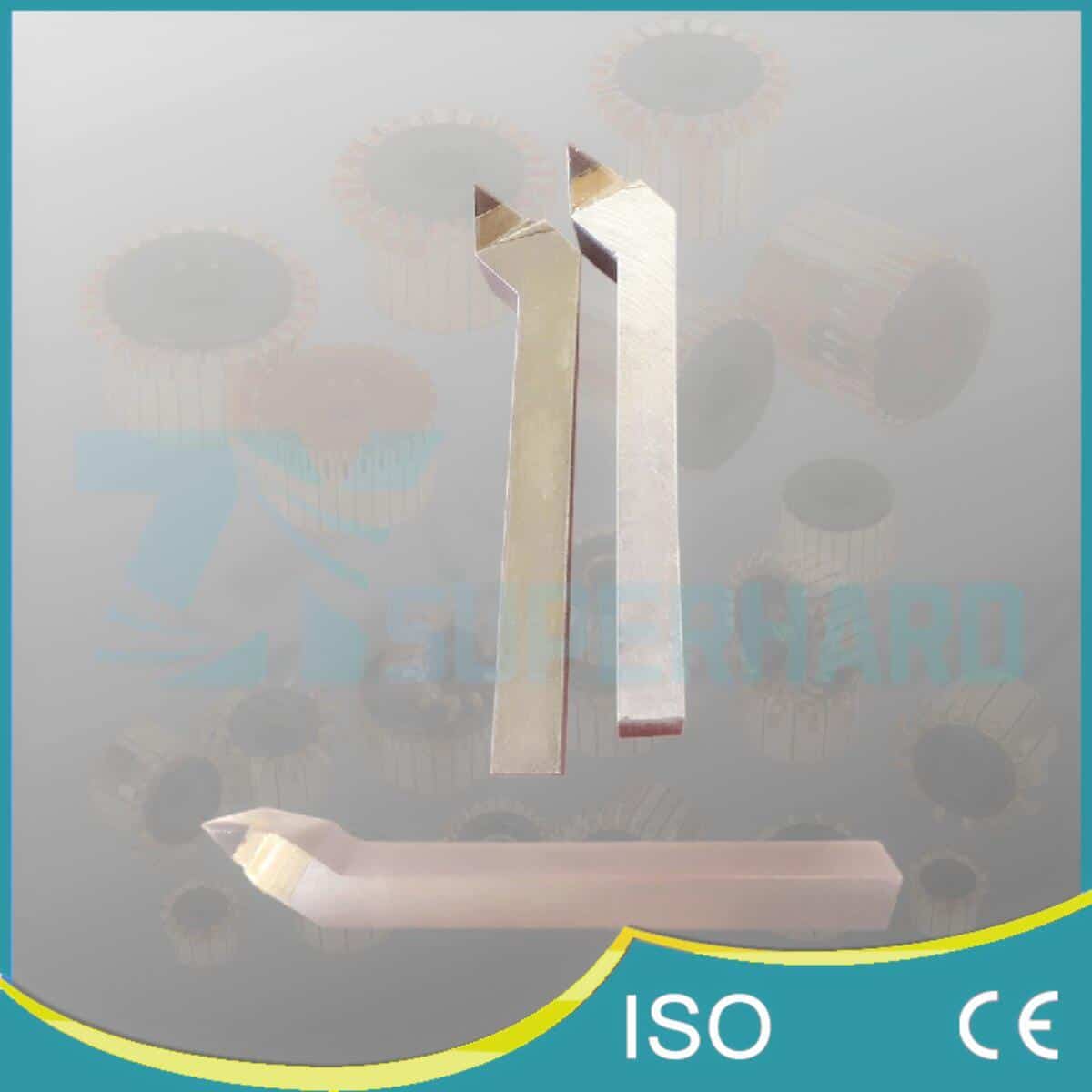

4. How to dress periphery grinding wheels

In the process of tool grinding, the grinding wheel’s working surface will be blocked by grinding debris. If we continue to operate it because the abrasive exposed cutting edge part is smaller, the cutting ability is reduced, the grinding pressure is increased, and the vibration of the machine tool will be increased, the grinding wheel produces a whistling sound for affecting the processing quality, then need to dress.

• By dressing, the grinding wheel can be kept in a good processing state to ensure processing efficiency and quality. The more smooth the grinding wheel dressing, the smaller the roughness of the machined surface.

• Peripheral grinding machine generally has its own dressing system, including a cleaning wheel and dressing wheel.

• Usually peripheral grinding wheel is trimmed by green silicon carbide or white corundum grindstone.

• Commonly used grain size F80-F500 according to the grinding wheel grain size and fracture requirements;

• Hardness generally selected soft or medium-soft level (J-K)

5. FAQ and analysis

1. Fast consumption of grinding wheel:

A. Grinding wheel threshing too fast; B. Low abrasive strength.

2. Workpiece burn:

A. The grinding wheel is not sharp enough; B. whether the appropriate parameter Settings; C. The device is abnormal.

3, the workpiece surface roughness is poor:

A. Whether the grinding wheel size selection is appropriate; B.Whether the processing parameters are reasonable; C. Coolant.

4. Abnormal machining accuracy:

A. Breaking edge; B. Parallel flatness; C. Size.