-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

PCD Tools for Graphite Milling & Drilling

Conquer abrasive graphite with our specialized PCD tools. Engineered for high-precision milling and drilling, and fully customizable to your exact specifications for applications like EDM electrodes and graphite molds.

Eliminate Tool Wear and Boost Productivity in Graphite Machining

Graphite’s extreme abrasiveness is notorious for destroying conventional carbide tools, leading to constant downtime, high tooling costs, and inconsistent part quality. ZYsuperhard’s PCD Graphite Machining Tools are the definitive solution. Specifically engineered for the challenges of graphite milling and drilling, our PCD end mills and drills deliver unparalleled performance, transforming your manufacturing process.

Why PCD is the Superior Choice for Graphite

- Massive Increase in Tool Life: The exceptional hardness of Polycrystalline Diamond offers unmatched resistance to the abrasive wear from graphite dust. Expect tool life 50 to 100 times longer than uncoated carbide, drastically reducing tool changes and operational costs.

- Flawless Surface Finish & Accuracy: PCD maintains an ultra-sharp cutting edge, which is critical for cleanly shearing graphite without causing chipping or breakout. This results in superior surface finishes and the ability to machine fine details, sharp corners, and clean holes—essential for high-quality EDM electrodes and precision molds.

- Drastically Faster Cycle Times: The high thermal conductivity of PCD allows heat to dissipate quickly from the cutting zone. This enables you to run at significantly higher cutting speeds and feed rates compared to carbide, slashing cycle times and increasing throughput.

- Improved Dust Management: A sharp PCD tool produces more manageable chips rather than the fine, abrasive powder generated by a wearing carbide tool, which can simplify dust extraction and create a cleaner working environment.

Engineered for Peak Performance in Graphite

- Optimized PCD Grades: We utilize premium PCD grades specifically selected to provide the ideal balance of extreme wear resistance and toughness required for demanding graphite applications.

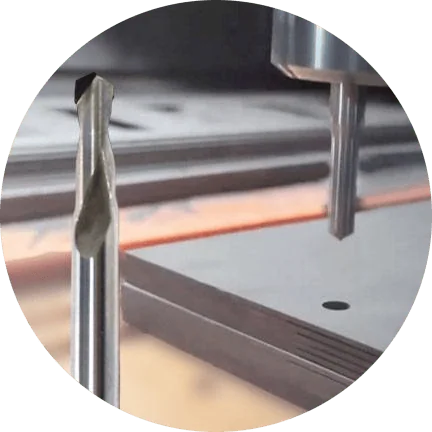

- Precision Edge Geometry: Our tools are manufactured with exceptionally sharp, precision-ground cutting edges and polished flutes to ensure clean cuts and facilitate efficient chip/dust evacuation.

- Application-Specific Designs: We offer a complete range of geometries, including End Mills (Flat, Ball Nose, Corner Radius) and specialized Drills, designed with optimal back angles (typically ≥ 10°) for graphite.

- High-Rigidity Tool Body: The solid carbide body provides maximum stability, eliminating vibration to ensure high-precision milling and drilling results.

Core Applications:

Our PCD tools are the industry standard for machining all grades of graphite across various applications:

- EDM Electrode Manufacturing: Easily mill complex 3D contours, thin ribs, and sharp details while achieving the ultra-smooth finishes required for optimal EDM performance.

- Graphite Molds & Crucibles: Accurately mill graphite molds for glass forming and casting, and drill precise locating holes with burr-free edges.

- Graphite Fixtures & Components: Excel at contour milling, pocketing, slotting, and drilling features in graphite jigs, bearings, seals, and other functional parts.

- Graphite Plate Processing: Efficiently perform face milling, slotting, drilling, and creating smooth, burr-free chamfered edges on graphite plates.

Fully Customizable Solutions

We specialize in custom PCD graphite machining tools. Whether you need specific end mill or drill geometries, require particular diameters, lengths, flute counts, corner radii, point angles, application-specific PCD grades, or tools based entirely on your drawings, our engineering team is ready to collaborate with you to design and manufacture the optimal solution for your graphite machining operation.

Significantly improve your graphite machining efficiency, drastically reduce tooling costs per part, and achieve consistently superior part accuracy and finish. Contact us to discuss your specific graphite machining application.