-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

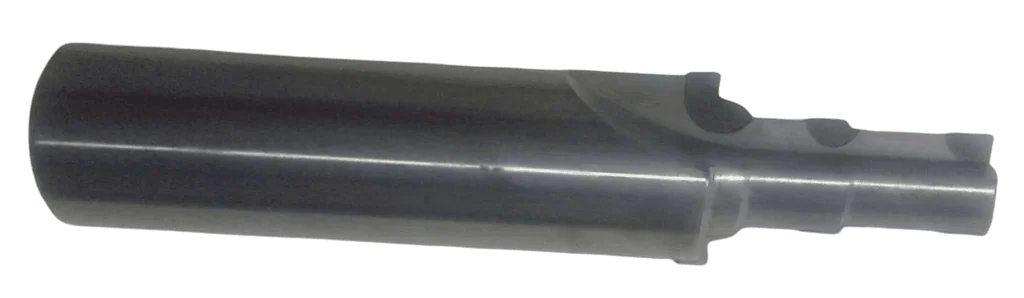

PCD Step Forming Reamer

Produce complex stepped holes in aluminum & composites in a single pass. This custom PCD step forming reamer ensures high precision, superior finish, and long tool life.

Precision Custom PCD Step Forming Reamers for Complex Hole Machining

Maximize efficiency and achieve exceptional accuracy when producing complex stepped holes with ZY SUPER HARD’s custom-engineered PCD Step Forming Reamers. Designed to machine multiple diameters, chamfers, or other forms in a single pass, these tools are ideal for high-precision applications in Automotive, Aerospace, Electronics, Hydraulic, and Wind Power components made from cast aluminum alloys, silicon aluminum alloys, and various composites.

Engineered for Performance and Longevity:

- Consolidated Machining in One Pass: By integrating multiple diameters and potentially intermediate forms (like chamfers or radii) into a single, precisely ground tool profile, our step forming reamers drastically reduce cycle times, eliminate tool changeovers for sequential operations, and minimize tolerance stacking errors, leading to higher overall part accuracy.

- Premium PCD Cutting Edges: Utilizing the extreme hardness and wear resistance of Polycrystalline Diamond (PCD), selected for optimal performance in your specific material, these reamers deliver outstanding tool life. This is especially true when machining abrasive materials like high-silicon aluminum or composites, where PCD significantly outperforms carbide, ensuring process stability and reducing cost per hole.

- Exceptional Hole Quality & Precision: Engineered and meticulously finish-ground to your exact specifications, these tools ensure excellent concentricity between stepped diameters, precise hole straightness, accurate bore location, and superior surface finish. Achieve tight tolerances reliably, often reducing or eliminating subsequent finishing steps.

- Robust Shank Construction: Tailor your tool with either a Solid Carbide shank for maximum rigidity and vibration damping (ideal for the highest precision requirements and chatter-free machining) or a high-quality Steel shank providing a durable and cost-effective option, depending on your application’s specific needs. Both ensure a stable platform for the demanding cutting action.

- Stable Cutting Performance: The inherent stability derived from the rigid shank and the sharp, durable PCD edges ensures smooth, consistent cutting performance, maintaining control over roughness, surface quality, and dimensional size throughout the tool’s extended life.

Application Focus:

Our custom PCD step forming reamers provide significant advantages in manufacturing parts with multi-diameter bores requiring high precision, such as:

- Automotive: Machining complex, stepped bores with tight concentricity and finish requirements in aluminum valve bodies, transmission components, pump housings, ABS manifolds, and steering system parts.

- Aerospace: Creating precise, multi-diameter holes with specific chamfers or radii in hydraulic manifolds, actuator housings, landing gear components, and structural parts made from aluminum alloys or composites.

- Electronics: Producing intricate stepped mounting holes or functional features in complex aluminum enclosures, heat sinks, or potentially composite electronic chassis components.

- Hydraulic Systems: High-precision finishing of multi-diameter stepped bores in valve blocks, pump bodies, and cylinder components.

- Wind Power: Potential applications in machining precise stepped holes in composite blade roots or aluminum nacelle structural components where accuracy and efficiency are key.

Made to Your Exact Specifications:

Every ZY SUPER HARD PCD Step Forming Reamer is a bespoke solution. We manufacture each tool based on your specific part drawing, meticulously finish-grinding it to the required hole diameters, tolerances, step transitions (chamfers/radii), overall lengths, shank configurations, and first-cut geometries. Our team works collaboratively with you to design and deliver the optimal tool for your unique and challenging hole-making requirements.

Invest in a custom PCD Step Forming Reamer to consolidate operations, drastically improve precision and consistency, extend tool life exponentially, and reduce your overall manufacturing cost per part for complex hole machining. Contact ZY SUPER HARD today to discuss your application.