-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

PCD Reamer for Precision Hole Finishing

Achieve ultra-precise holes with our PCD reamers. Designed for high-speed machining of aluminum, composites, and other non-ferrous materials. Custom solutions available.

Unleash Unmatched Performance and Precision with Our Advanced PCD Reamers

Our Polycrystalline Diamond (PCD) reamers are engineered to meet the most stringent demands of modern manufacturing, delivering exceptional hole quality, significantly extended tool life, and increased productivity. Designed for precision finishing of through-holes and blind holes, these tools excel in machining a wide variety of non-ferrous metals and abrasive non-metallic materials.

Why Choose Our PCD Reamers?

- Exceptional Tool Life: The PCD cutting edges offer unparalleled hardness and wear resistance, lasting many times longer than conventional carbide or HSS reamers, especially in challenging materials. This dramatically reduces tool changes, machine downtime, and overall tooling costs.

- Superior Hole Quality & Surface Finish: Achieve mirror-like surface finishes (low Ra values) and tight dimensional tolerances (e.g., H7 and tighter) consistently. The sharp, durable cutting edges minimize built-up edge (BUE) and ensure clean, precise bores, often eliminating the need for secondary finishing operations.

- Increased Productivity: Capable of high-speed machining (higher Vc – cutting speed in m/min or SFM) and optimized feed rates (fz – feed per tooth in mm or IPT), our PCD reamers significantly reduce cycle times per part, boosting your production output.

- Versatility in Application: Ideal for a wide range of materials including:

- Aluminum Alloys: All grades, including high-silicon aluminum (e.g., AlSi7Mg, A356).

- Copper and Brass Alloys: Prevents adhesion and ensures smooth cutting.

- Magnesium Alloys

- Metal Matrix Composites (MMCs)

- Carbon Fiber Reinforced Polymers (CFRP)

- Glass Fiber Reinforced Polymers (GFRP)

- Graphite

- Green or Pre-sintered Ceramics

- Engineered Plastics and Wood Composites (with abrasive fillers)

- (Note: Not recommended for ferrous materials like steel or cast iron due to chemical affinity at machining temperatures.)

- Consistent Performance: Maintain stable and reliable machining performance over extended periods, ensuring part-to-part consistency crucial for quality control in industries like automotive, aerospace, electronics, and medical manufacturing.

- Excellent Thermal Conductivity: PCD helps dissipate heat effectively from the cutting zone, reducing thermal stress on the workpiece and tool, and enabling efficient dry or Minimum Quantity Lubrication (MQL) machining in suitable applications.

Key Design Features & Specifications

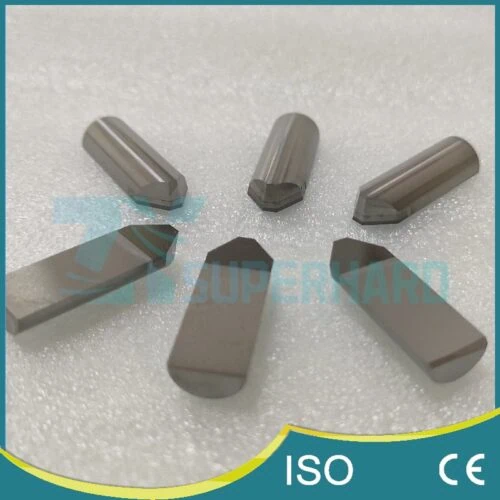

- PCD Grade: We utilize premium-grade PCD material from leading global suppliers, selected based on your specific application requirements for optimal performance (e.g., grain size, binder content).

- Substrate Material: High-quality tungsten carbide or tool steel bodies provide robust support and rigidity for the PCD tips, ensuring stability during high-performance cutting.

- Brazing Technology: Advanced vacuum brazing techniques ensure a strong and reliable bond between the PCD tip and the tool body, critical for tool integrity and performance.

- Flute Geometry:

- Number of Flutes (Z): Available with various flute counts (e.g., 2, 4, 6, 8, or more, depending on diameter and application) to balance chip evacuation and surface finish.

- Flute Style: Options include:

- Straight Flutes: For general-purpose reaming.

- Helical Flutes (Right Hand Spiral / Left Hand Spiral): For improved chip evacuation, smoother cutting action, and enhanced surface finish, especially in blind holes or challenging materials.

- Shear Flutes: For specific applications requiring particular cutting dynamics.

- Cutting Edge Geometry: Precision ground cutting edges with optimized rake angles, clearance angles, and helix angles for efficient material removal and superior finish.

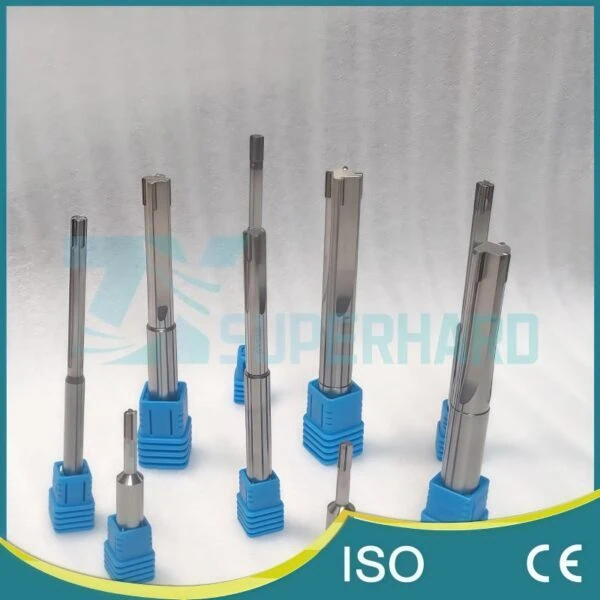

- Shank Options:

- Straight Cylindrical Shanks: For standard collet chucks and hydraulic holders.

- Taper Shanks: Including Morse Taper (MT), HSK, BT, CAT, and other common machine tool interfaces for high-precision and high-rigidity mounting.

- Monoblock Design: Reamer and holder integrated into a single unit for minimized runout and enhanced stability.

- Coolant Delivery:

- Internal Coolant (Through-Tool Coolant): Delivers coolant directly to the cutting zone for optimal cooling, lubrication, and chip evacuation, especially critical for deep holes and high-speed operations. Radial or axial exits available.

- External Coolant: Suitable for applications where through-tool coolant is not available or necessary.

- Diameter Range (D): Available in a wide range of metric and inch diameters (e.g., from Ø3mm to Ø150mm, or larger upon request).

- Overall Length (L) & Flute Length (L1): Various standard lengths available, and custom lengths can be manufactured.

- Maximum Reaming Depth (L4): Specified based on tool design and application.

- Tolerance Class: Designed to achieve high hole tolerances (e.g., IT5, IT6, H7).

- Runout Control: Manufactured to tight runout tolerances (TIR) to ensure precision.

Parameters & Operating Guidelines

Successful PCD reaming depends on optimizing cutting parameters for your specific material, machine tool rigidity, and setup. The following table provides general starting values for common material groups.

| Material Group | Example Material | Cutting Speed Vc (m/min) | Feed fz (mm/tooth) |

|---|---|---|---|

| Low-Silicon Aluminum | Al 6061 | 300 – 700 | 0.05 – 0.20 |

| High-Silicon Aluminum | AlSi12 (A380) | 100 – 400 | 0.03 – 0.15 |

| Copper Alloys | Brass, Bronze | 150 – 500 | 0.04 – 0.18 |

| Composites | CFRP | 80 – 250 | 0.02 – 0.10 |

Note: The values in this table are general starting guidelines. Optimal parameters can vary based on specific application conditions, machine stability, and desired outcomes. Always start cautiously and adjust parameters as needed. Contact us for detailed parameter recommendations tailored to your application.

- Depth of Cut (Radial): Reamers are finishing tools; typical stock removal is small.

- Coolant: Use of appropriate coolant (type, pressure, flow rate) is highly recommended to maximize tool life and performance, especially in high-silicon aluminum and composites. MQL or dry machining may be possible in certain applications.

Industries Served

- Automotive (Engine blocks, cylinder heads, transmission parts, brake components)

- Aerospace (Airframe components, engine parts, landing gear)

- Electronics (Housings, connectors)

- Medical (Implants, instruments)

- General Machining & Precision Engineering

- Energy

- And more…

Customization – Tailored to Your Exact Needs

We understand that standard tooling may not always meet unique application requirements. We specialize in providing custom-engineered PCD reamer solutions. Provide us with your tool drawings or detailed tool parameter information (such as specific bore diameters and tolerances, step reamer designs, special profiles, shank configurations, or application-specific PCD grades and geometries), and our experienced engineering team will manufacture a PCD reamer precisely tailored to your needs. We can develop:

- Specific Bore Diameters and Tolerances

- Step Reamers: Combining multiple diameters or operations (e.g., reaming and chamfering) in a single tool for enhanced efficiency and concentricity.

- Special Profile Reamers

- Guide Pad Reamers: For enhanced guidance and straightness in long bores.

- Unique Shank Configurations or Lengths

- Application-Specific PCD Grades and Geometries

- Monoblock Solutions (Reamer with Holder Assembly) for ultimate precision.

Contact us today to discuss your PCD reaming requirements and let our experts help you achieve superior results!