-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

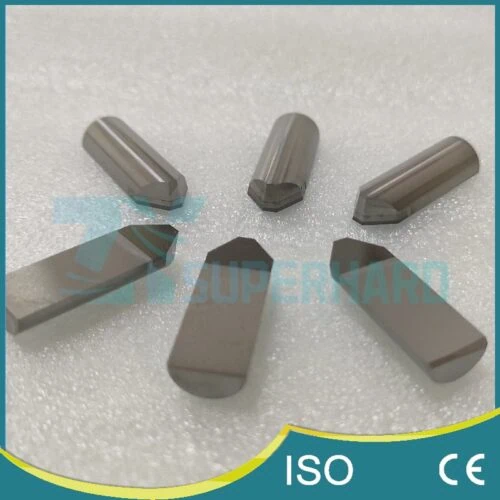

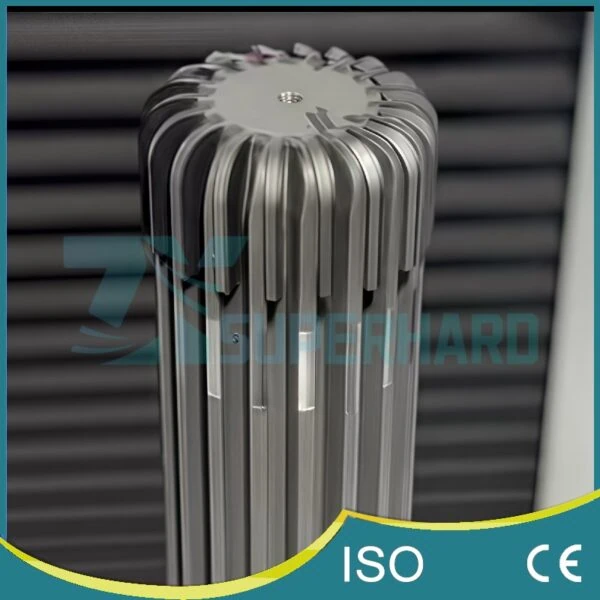

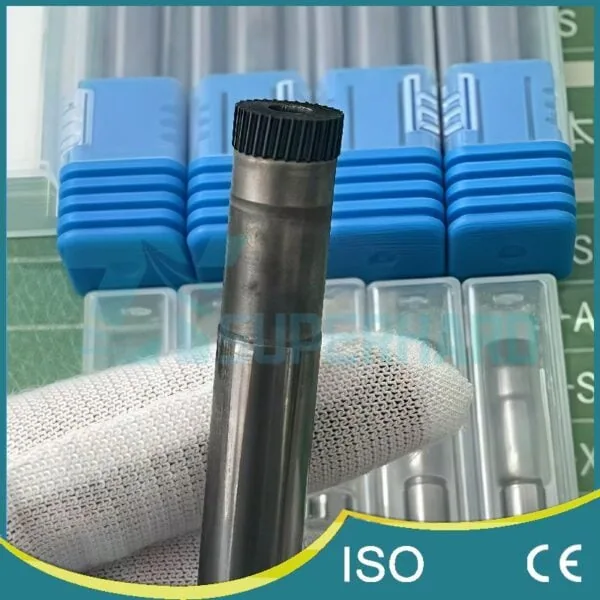

PCD/PKD Multi-Tooth Milling Cutter

Unlock unparalleled machining efficiency. Our Multi-Tooth PCD Cutter enables dramatically faster feed rates while producing a flawless, mirror-like finish in a single pass. It’s the ultimate solution for high-volume, high-precision manufacturing.

Beyond Speed: The New Standard in Machining Efficiency and Finish

In modern manufacturing, the goal is always to machine faster without sacrificing quality. Traditional milling cutters often force a compromise: increase speed and risk a poor finish, or slow down for precision and lose productivity. Our PCD Multi-Tooth Milling Cutter is engineered to break this compromise. By intelligently combining a high-density cutting edge design with the extreme durability of Polycrystalline Diamond, this tool represents a leap forward in finishing operations.

The Multi-Tooth Advantage: How More Edges Transform Performance

The revolutionary performance of this cutter lies in its multi-tooth geometry. While a standard end mill may have 2 to 4 flutes, our design can incorporate up to 30 precision-ground PCD cutting edges. This isn’t just an incremental improvement; it fundamentally changes the physics of the cut.

- Exponentially Higher Feed Rates: With the cutting work distributed across many more teeth, you can increase machine feed rates significantly without overloading the tool. This translates directly to shorter cycle times and higher throughput.

- Flawless Surface Finish: The magic of the multi-tooth design is the dramatically reduced chip load on each individual tooth. This creates an incredibly stable, lower-impact cutting action that virtually eliminates chatter, vibration, and tool marks. The result is a mirror-like surface finish (as fine as Ra 0.1-0.2μm) directly off the machine, often eliminating the need for secondary polishing or grinding operations.

- Reduced Cutting Pressure: Lower force per tooth means less deflection on the workpiece, which is critical when machining thin-walled or delicate parts. This ensures superior dimensional accuracy and part integrity.

Powered by PCD: The Perfect Material for a Demanding Design

A multi-tooth design is only effective if every cutting edge maintains its sharpness. That’s why our cutters are tipped with premium-grade Polycrystalline Diamond (PCD). PCD offers:

- Extreme Hardness & Wear Resistance: It easily handles abrasive materials like high-silicon aluminum and carbon fiber composites, ensuring all teeth wear evenly and the tool maintains its precision profile for an exceptionally long lifespan—10 to 50 times that of carbide.

- Excellent Thermal Conductivity: PCD rapidly dissipates heat away from the cutting zone, preventing thermal damage to the workpiece and extending tool life, especially at the high speeds this cutter is designed for.

Optimized for Your Industry’s Most Demanding Applications

- Aerospace & Composites: Machine carbon fiber reinforced polymers (CFRP) and other composites with minimal delamination, fiber pull-out, or burrs. Achieve perfect finishes on aluminum aircraft structural components.

- 3C Electronics & Automotive: Produce mirror-finish metal frames for smartphones, shiny decorative automotive trim, and high-performance aluminum heat sinks with unmatched speed and repeatability.

- Precision Components: Ideal for machining copper electronic connectors and ceramic-matrix parts where dimensional stability and a flawless surface are non-negotiable.

Partner with Us for a Custom-Engineered Solution

While our standard offerings cover a wide range of applications, we recognize that true optimization comes from perfect alignment with your process. Our engineering team will partner with you to develop a custom PCD Multi-Tooth Milling Cutter tailored to your exact needs. We can modify the diameter, number of teeth, cutting geometry, and PCD grade to create a tool that provides you with a decisive competitive advantage. Contact us to start engineering your solution.