-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

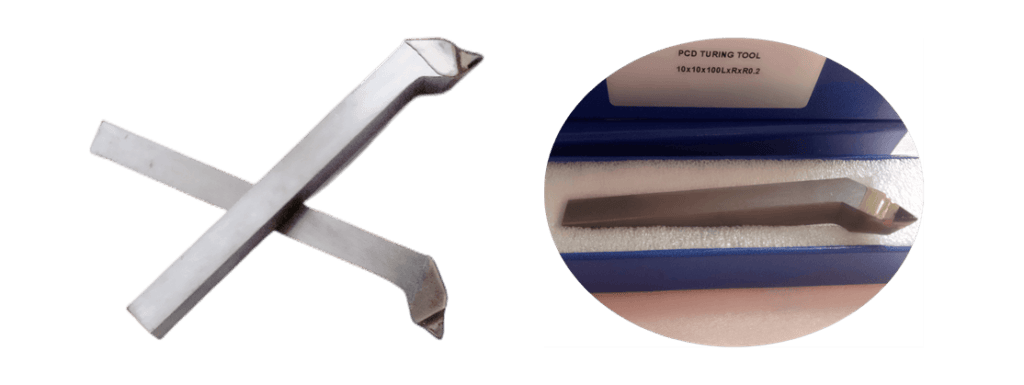

PCD Motor Commutator Turning Tools

Precision PCD tools for fine turning motor commutators. Ensures superior finish, brightness & cylindricity for quiet motor operation. High durability, cost-effective. Fine tip radii (e.g., R0.025) available.

Achieve Superior Motor Performance with High-Precision PCD Commutator Turning Tools

ZYsuperhard’s PCD Motor Commutator Turning Tools are expertly engineered to meet the demanding requirements of producing high-quality electric motor commutators. Turning copper commutators, with their abrasive insulating segments (typically mica), presents unique challenges that Polycrystalline Diamond (PCD) is perfectly suited to overcome, ensuring both exceptional surface finish and extended tool life crucial for optimal motor function.

Why PCD is Essential for Commutator Turning:

- Unmatched Wear Resistance: PCD easily handles the abrasive nature of mica or other insulators between copper bars, dramatically outlasting conventional carbide tools and maintaining consistent cutting performance over long production runs.

- Chemical Stability with Copper: PCD remains chemically inert when cutting copper, preventing the formation of Built-Up Edge (BUE) that plagues other tool materials. This ensures a clean cut and prevents surface finish degradation.

- Sharp & Durable Edge Retention: PCD maintains an ultra-sharp cutting edge far longer than other materials. This is vital for cleanly shearing copper, producing the mirror-like finishes essential for optimal brush contact, reduced electrical noise, and longer brush life.

- High Thermal Conductivity: Efficiently dissipates heat generated during cutting, protecting the integrity of the PCD edge and the commutator surface, especially at high speeds.

Key Features & Design Advantages:

- Ultra-Precise Cutting Edges: Utilizing advanced grinding techniques, we ensure exceptionally sharp and precisely profiled PCD cutting edges for burr-free machining and accurate commutator geometry.

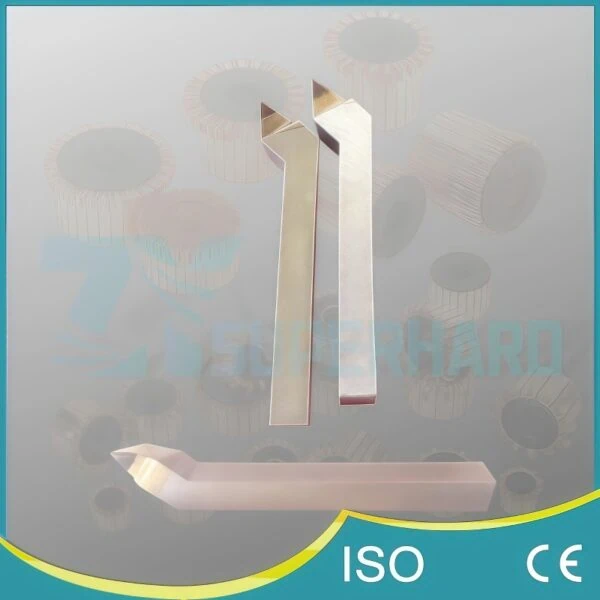

- High-Strength Alloy Steel Shanks: Tool shanks are crafted from alloy steel, often undergoing forging and precision milling, to provide maximum rigidity, strength, and stability during the turning process.

- Application-Specific Geometries: We offer tools designed for various commutator turning operations, from roughing to ultra-fine finishing. Fine turning tools can be produced with tip radii as small as R0.025mm (customizable) to achieve superior surface quality.

- Customization Expertise: We specialize in developing custom PCD commutator tools tailored to your specific commutator design, required tolerances, corner radii, shank dimensions, and machine setup.

Performance Benefits & Expected Results:

- Exceptional Surface Finish & Brightness: Consistently achieve mirror-like finishes (low Ra values) and high brightness on copper segments, critical for reducing brush wear, minimizing electrical sparking, and lowering operational noise.

- Tight Dimensional & Geometric Control: Maintain precise control over commutator diameter, roundness, runout, and cylindricity, contributing to consistent motor performance and reduced vibration, resulting in quiet motor operation after installation.

- Significantly Longer Tool Life: Experience tool life potentially tens or even hundreds of times greater than traditional carbide tools in this application, drastically reducing machine downtime for tool changes and lowering the overall tooling cost per commutator produced.

- Increased Productivity: PCD allows for significantly higher cutting speeds and potentially higher feed rates on copper, boosting throughput.

- Reliable Quality & Overall Cost-Effectiveness: Rigorous quality control ensures dependable performance. Combined with extended life and efficiency gains, our PCD tools offer high cost performance.

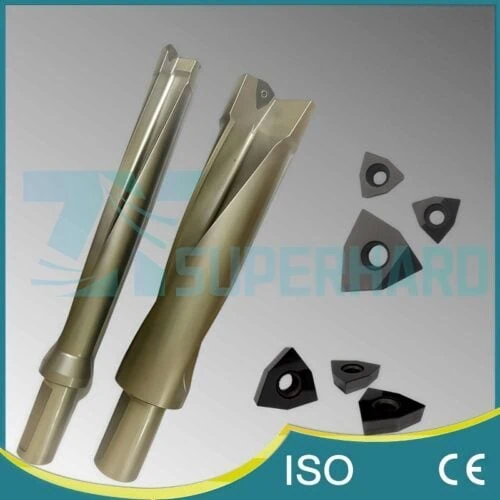

Available Tool Types Include (Standard & Custom):

- PCD Finishing Shaving Cutters: Designed for the final pass to achieve optimal surface finish and roundness.

- 105° PCD Motor Commutator Left-Hand Cutters: For specific profile requirements or machine orientations.

- Standard PCD Motor Commutator Cutters: General-purpose turning tools for commutators.

- PCD Motor Commutator Cutters with Wide Edge: Suitable for specific applications requiring broader engagement.

- Plus custom designs engineered to your exact specifications.

Trust ZYsuperhard for reliable, high-performance PCD tooling solutions that enhance the quality and efficiency of your motor commutator turning processes. Contact us to discuss your specific requirements.