-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

PCD Drill Reamers For Power System Cylinder Head Processing

Optimize aluminum cylinder head hole machining with PCD drill reamers. Precision tools for valve guides/tappets/spark plugs feature vibration control & G2.5 balance ensuring stability and high efficiency.

Advanced PCD Drill Reamers for High-Precision Cylinder Head Machining

Maximize efficiency, precision, and process reliability in your automotive cylinder head production lines with this specialized portfolio of Polycrystalline Diamond (PCD) Drill Reamers. Engineered specifically for the demanding task of machining critical holes in aluminum alloys – including valve guides, tappet bores, spark plug holes, and clearance features – these tools incorporate innovative designs tailored to overcome common processing challenges and deliver superior results.

Why PCD Excels in Cylinder Head Processing

Aluminum cylinder heads require high-volume production combined with exacting tolerances on numerous features. PCD tooling is the enabling technology, offering:

- Extreme High-Speed Capability: PCD’s exceptional wear resistance allows for significantly higher cutting speeds and feeds compared to traditional carbide tools, drastically reducing machining cycle times per cylinder head.

- Superior Accuracy & Surface Finish: The low friction coefficient and ability to hold a sharp edge result in excellent surface finishes(Ra) and tight dimensional control, vital for engine performance, sealing, and component assembly.

- Unmatched Tool Life: In continuous production, PCD tools provide vastly longer operational life, minimizing costly tool changes and machine downtime, leading to a lower overall cost per manufactured part.

Targeted Solutions for Critical Cylinder Head Features

Our PCD drill reamers employ application-specific designs to master the unique challenges of each hole type:

- Tappet & Valve Guide Holes – Roughing Stage:

- Challenge: Controlling vibration and managing long aluminum chips during high-efficiency hole opening.

- Solution: Tools often incorporate an end guide design providing enhanced stability to minimize tool vibration at high feed rates. Flute geometries are optimized to prevent chip winding and ensure effective chip breaking or evacuation.

- Benefit: Enables stable, aggressive rough machining, preparing holes reliably for the critical finishing stage while maximizing throughput.

- Tappet & Valve Guide Holes – Finishing Stage:

- Challenge: Achieving exceptional cylindricity, dimensional accuracy, and surface finish, sometimes with variations in surrounding wall thickness.

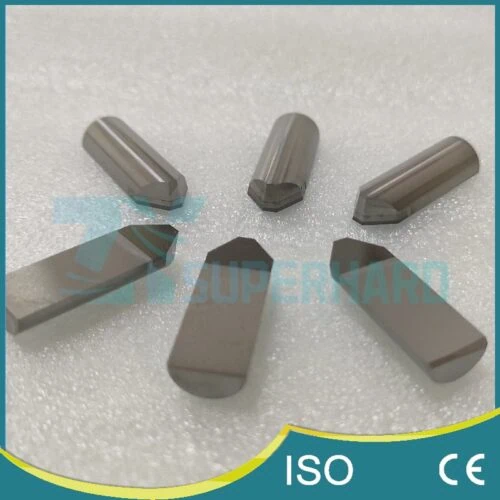

- Solution: Often utilizes advanced geometries like a six-edge unequal flute distribution. This design inherently enhances operational stability, counteracts uneven cutting forces from inconsistent wall stock, and maintains superior hole geometry. Achieves outstanding precision control, with end and diameter runout (jump) typically held within 0.003mm.

- Benefit: Delivers the ultra-high precision required for hydraulic tappet function and valve guide fits, ensuring engine performance and reliability.

- Spark Plug Hole Processing:

- Challenge: Efficiently machining potentially complex profiles often requiring multiple conventional tools.

- Solution: Employs an optimized PCD tool design that frequently concentrates multiple processing steps (e.g., counterboring, chamfering, threading preparation) into a single, specialized tool. Leverages the optimal combination of sharp PCD cutting edges and a robust carbide tool body for high-speed, reliable execution.

- Benefit: Streamlines the process, reduces the number of tools required, decreases cycle time, lowers tooling inventory costs, and ensures consistent quality.

- Clearance / Cross Hole Finishing:

- Challenge: Ensuring chips are smoothly evacuated, especially from intersecting holes, to prevent packing and tool breakage.

- Solution: Features flute designs and cutting edge geometries specifically engineered for highly effective chip removal. Ensures smooth discharge of aluminum chips away from the cutting zone, even in complex cross-hole situations.

- Benefit: Eliminates chip packing issues, prevents subsequent cleaning operations, increases production efficiency, and enhances overall process safety.

Common Advanced Features Across the Product Line

To further boost performance and reliability, many of these tools incorporate:

- G2.5 Dynamic Balance: Precision balancing minimizes vibration during high RPM operation, reducing wear on the machine tool spindle and ensuring greater machining stability and accuracy.

- Internal Coolant Delivery: Designed with through-tool coolant channels to deliver coolant directly to the cutting edges, providing optimal cooling, lubrication, and chip flushing for extended tool life and improved surface quality.

- Versatile Holder Interfaces: Offered with various industry-standard interfaces, such as heat shrink fit, solid monobloc styles, or flange transfer designs, ensuring secure, accurate, and rigid mounting in your machine tool.

Comprehensive Benefits for Cylinder Head Manufacturing

- Increased Productivity: Substantially faster cycle times due to high-speed PCD machining.

- Enhanced Quality & Consistency: Tighter tolerances achieved on critical hole features.

- Improved Process Stability & Reliability: Reduced vibration and superior chip control lead to more secure operations.

- Lower Overall Manufacturing Costs: Driven by significantly longer tool life, reduced downtime, and potential process consolidation.

Custom-Engineered for Your Specific Cylinder Head

Given the variations in cylinder head designs and production environments, these PCD drill reamers are primarily custom-engineered solutions. We collaborate closely with your team, analyzing your specific material, hole requirements (diameter, depth, tolerances, features), machine specifications, and productivity goals to design and deliver the optimal tooling strategy.

Engage with our powertrain machining application experts to explore how advanced PCD drill reamer technology can optimize your cylinder head processing line.