-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

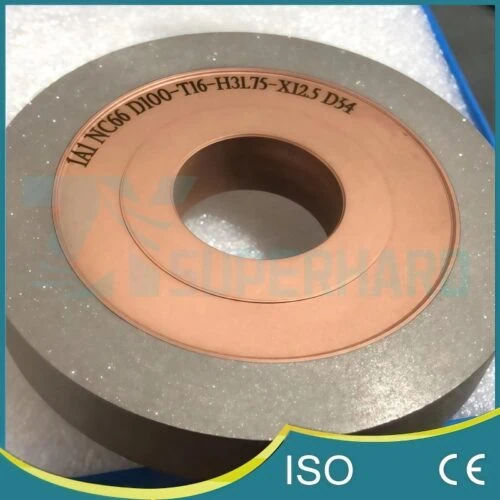

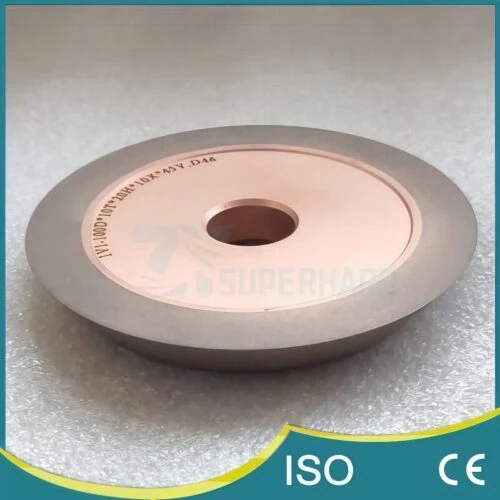

Mono Crystalline Diamond MCD SCD Milling Cutter

ZYsuperhard MCD milling tools achieve mirror finishes on soft metals (Au, Ag, Al) & plastics (Acrylic). Single crystal diamond on carbide body ensures precision. Note: avoid Iron/CFRP. Custom options.

Characteristics and Advantages of MCD Material

Monocrystalline Diamond MCD is also called SCD, which means single crystal diamond. It is a single synthetic diamond with a yellow-like crystal.

MCD diamond is a synthesis diamond similar to a natural diamond. However, with the proper usage and application, MCD diamond can enhance cutting tools for high cutting performance to cut faster and smoother. Also, this can reduce manufacturing costs for producing tools or machine parts from the MCD cutting tools.

Application Scope and Limitations of MCD

MCD is unsuitable for metal cutting, such as iron and CFRP, because cutting metal with cutting tools will cause heat of 700-1,000°C, which will melt MCD and reduce its tool life. So mainly used for High-Gloss Mirror Finishing Of Various Soft Metals, Gold, Silver, Copper, Aluminum Alloy, Zinc Alloy And Non-Metallic Materials, Acrylic, Pvc, Pc, Plastic, and Other Materials.

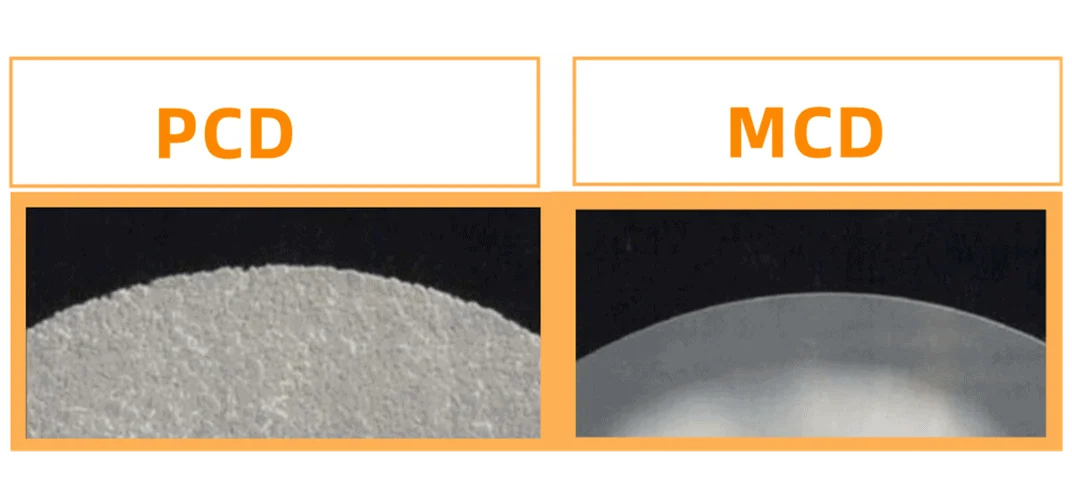

Comparison Between PCD and MCD Tools

Compared to PCD, MCD cutting tools have approximately 3.5-10 times more tool life but around four times more manufacturing cost than MCD tools.

We supply different types of MCD cutters, MCD milling inserts, MCD lathe turning cutters, MCD chamfering cutters, and MCD highlight polishing cutters, also provide customized ones.

Comparison of Mirror machining effect for PCD and MCD

Important Usage, Handling, and Inspection Guidelines for MCD Tools:

Single Crystal Diamond (MCD/SCD) tools possess exceptionally sharp cutting edges capable of achieving mirror finishes, but they are also inherently brittle. Adhering to proper handling, usage, and inspection protocols is absolutely critical to prevent premature edge chipping or tool failure and to maximize the significant investment these tools represent.

- Machine & Setup Rigidity: Employ MCD tools exclusively in well-balanced, vibration-free machining environments. Maximize the rigidity of the workpiece clamping system, the tool holder assembly, and the entire machine tool structure to provide superior vibration damping and operational stability.

- Optimal Cutting Speed: Generally, higher cutting speeds reduce cutting forces when using MCD tools. Avoid utilizing excessively low cutting speeds, as this can increase cutting pressure and significantly heighten the risk of tool edge fracture. Always consult recommended starting parameters (refer to provided table or contact us) and optimize based on your specific machine and setup capabilities.

- Careful Engagement & Disengagement Protocol: Prevent any contact between the stationary MCD cutting edge and the workpiece or any other solid object. Never halt spindle rotation while the tool remains engaged with the workpiece. Ensure the tool path provides clear entry and exit before stopping rotation.

- Mandatory Edge Protection: The diamond edge is extremely susceptible to damage from impact or contact. When the tool is not actively in use or during storage, always protect the cutting edge using a suitable non-abrasive material like a dedicated rubber or plastic cap. Store each MCD tool individually in its protective case.

- Pre-Use Cleaning: Before mounting or using the tool, gently wipe the cutting edge area with a clean, appropriate solvent like alcohol to remove any contaminants.

- Non-Contact Inspection & Measurement: Crucially, always utilize non-contact measurement techniques for inspecting MCD tool edges and geometry. Optical instruments such as high-magnification microscopes, toolmaker’s microscopes, profile projectors, or optical CMMs are essential. Never use mechanical contact methods (e.g., styli, touch probes, calipers) directly on the diamond edge, as this will almost certainly cause damage.

- Safe Handling During Setup & Inspection: When handling the tool for installation or inspection that might involve proximity to other surfaces, use optical devices whenever possible to verify installation angles and runout. If temporary contact with holding fixtures or measurement stages is unavoidable, place soft interface materials like copper shims or clean plastic between the tool body/shank and the fixture – never directly contacting the diamond edge.

- Controlled Environment & Operator Skill: Maintain a clean machining environment, minimizing airborne dust and contaminants. Factors such as machine tool performance stability, coolant/lubricant type and delivery, ambient conditions (humidity), and the operator’s skill and experience significantly influence the achievable tool life and performance of MCD tools.

Comparison of various performance for different work piece being processed by MCD

| Work piece | Processing Way | Cutting Rate(m/min) | Feed Rate(m/min) | Cutting Depth(mm) |

| Fluorosilicone acrylate soft contact lenses | Turning | 100-200 | 0.4 | 0.1-1.5 |

| PMMA hard contact lenses | Turning | 100-200 | 0-04 | 0.1-1.5 |

| No electrolytic nickel (STAVAX) brass | Turning | 100-800 | 0.003-0.01 | 0.0005-0.001 |

| Milling | 50-1000 | 0.0005-0.003 | 0.0005-0.003 | |

| Oxygen free copper | Turning | 200-880 | 0.05 | 0.1 |

| Aluminum, aluminum alloy | Turning | 100-500 | 0.05-0.5 | 0.02-0.2 |

| Milling | 100-500 | 0.1-0.5 | 0.02-0.2 | |

| Gold jewelry | Turning | 1000 | — | —- |