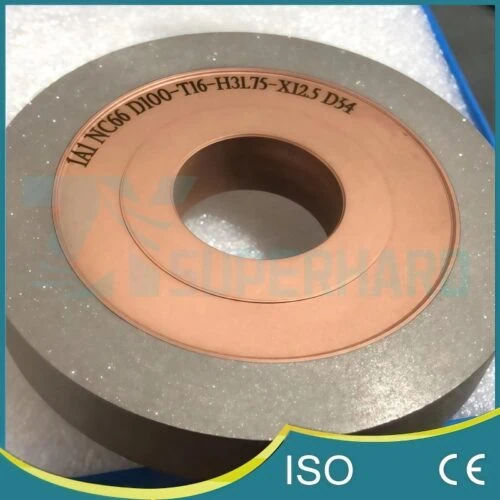

Metal Bond Diamond Grinding Wheels for Rough Grinding Ceramics

Power through demanding ceramic rough grinding operations with these highly durable Metal Bond Diamond Grinding Wheels from ZYsuperhard. Engineered specifically for high-stock removal on tough ceramic materials, they combine the resilience of a sintered bronze metal bond with the cutting power of coarse diamond grains, ensuring exceptional longevity and grinding efficiency.

Engineered for Tough Ceramic Roughing Applications

Rough grinding ceramics requires grinding wheels that can withstand significant abrasion and grinding forces while efficiently removing material. Our metal bond diamond wheels are purpose-built for this challenge:

- Highly Durable Bronze Metal Bond: Utilizes a robust bronze-based metal matrix, consolidated through a high-temperature sintering process. Compared to other bond systems (like resin or vitrified), metal bonds offer vastly superior wear resistance, impact resistance, and form-holding ability. This makes them the ideal choice for aggressive rough grinding stages where maintaining the wheel’s profile and ensuring maximum lifespan under heavy load are critical.

- High-Performance Diamond Abrasive: Diamond is the only abrasive capable of effectively and economically grinding most technical ceramics. We use quality diamond grains selected for their blocky shape and toughness, suitable for high-pressure rough grinding.

- Superior Grit Retention: The inherent strength of the sintered metal bond provides extremely strong mechanical retention of the coarse diamond grits, preventing premature grit pull-out and ensuring sustained cutting action even during demanding stock removal.

Coarse Grits for Maximum Material Removal Rate

These wheels are specifically configured with coarse diamond grit sizes to maximize roughing efficiency:

- Specified Grit Sizes: Primarily offered in industry-standard coarse grits of 40# and 60#.

- Roughing Functionality: These large diamond particles are designed for rapid material removal. Their primary function is to quickly grind away large amounts of stock material from ceramic workpieces, correct initial shape deviations, or prepare surfaces for subsequent semi-finishing or finishing steps using finer grit wheels. They prioritize removal rate over achieving a smooth surface finish.

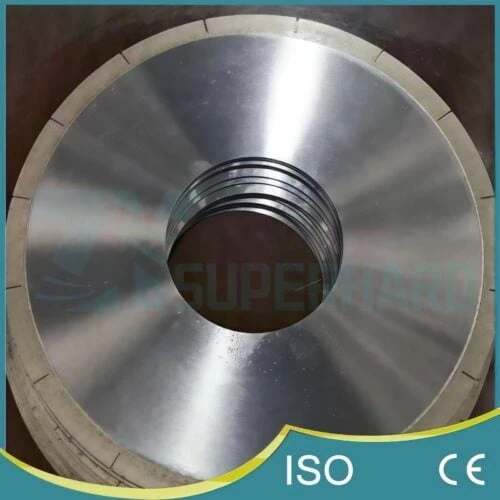

Custom Shapes for Application Versatility

Ceramic components come in countless forms, and grinding processes vary. ZYsuperhard addresses this by offering these wheels in fully customized shapes:

- Tailored to Your Drawings: We manufacture grinding wheels precisely according to your specific drawings, ensuring perfect fitment to your machine and optimal contact with your workpiece geometry.

- Versatile Geometric Forms: Capable of producing various standard and custom wheel shapes suitable for different ceramic grinding operations, including:

- Surface Grinding: Straight wheels (Type 1), cylinder wheels (Type 2), cup wheels (Type 6, 11).

- Cylindrical Grinding: OD and ID grinding wheels.

- Profile & Form Grinding: Wheels with specific contours or angles.

- Tool Grinding: Wheels for sharpening or shaping ceramic cutting tools.

Key Performance Advantages

- Exceptional Durability & Maximum Wheel Life: Robust metal bond resists wear for extended service.

- High Stock Removal Efficiency: Coarse diamond grits enable fast grinding cycles for roughing.

- Excellent Form Holding & Profile Stability: Metal bond maintains wheel shape integrity over time.

- Cost-Effective Ceramic Roughing: Long lifespan and high efficiency contribute to lower overall costs in the initial grinding stages.

Provide us with your detailed ceramic rough grinding application requirements and desired wheel shape drawing or specifications. Our team will assist in configuring a high-performance metal bond diamond grinding wheel tailored to your needs.