-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

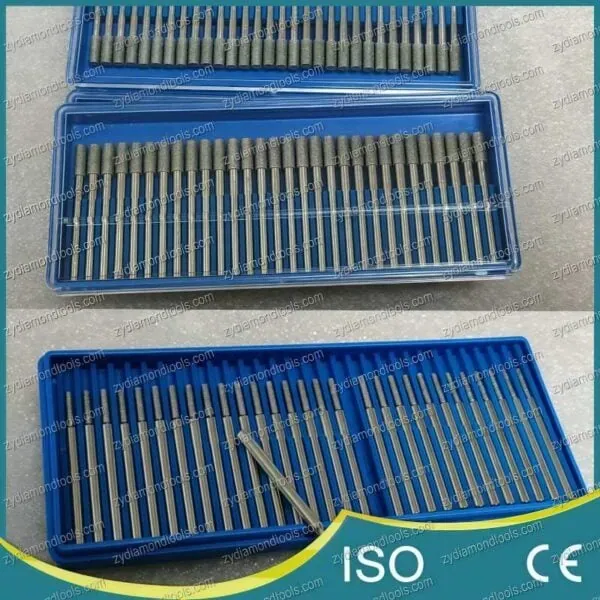

Electroplated Diamond Mounted Points / Burrs

Premium electroplated diamond mounted points/burrs for aggressive grinding and fine finishing on hard materials like carbide, ceramic, glass, and hardened steel. Available in various shapes and grits with consistent quality for production use. Ideal for grinding, deburring, shaping, and carving.

High-Performance Electroplated Diamond Mounted Points / Burrs

We provide durable and reliable electroplated diamond mounted points / burrs engineered for demanding industrial applications. These versatile tools, often referred to as diamond grinding heads or grinding points, deliver exceptional performance on a wide range of hard and brittle materials, ensuring efficiency and quality in your operations.

Superior Electroplated Diamond Technology:

Our electroplated diamond tools are manufactured using a precise process where a single layer of high-quality diamond abrasive is securely bonded to a steel shank using a nickel matrix. This method offers several advantages:

- Free-Cutting Action: The exposed diamond crystals provide an aggressive cutting rate and efficient material removal.

- Intricate Shapes: Allows for the creation of diverse and complex head shapes to suit various applications.

- Excellent Form Holding: Maintains profile integrity for precision tasks.

- Cost-Effective: Provides excellent value for numerous grinding, deburring, and shaping operations.

Key Features & Benefits:

- Premium Diamond Abrasive: Ensures maximum hardness for effectively machining the toughest materials, offering long service life compared to conventional abrasives.

- Versatile Head Shapes: Available in a wide array of shapes (cylindrical, ball, cone, taper, flame, inverted cone, etc.) to handle diverse tasks like internal grinding, contouring, deburring sharp edges, and intricate carving.

- Robust Electroplated Bond: Securely anchors the diamond particles, ensuring tool reliability and consistent performance crucial for production environments.

- Standard Shank Sizes: Manufactured with industry-standard shank diameters (e.g., 3mm, 6mm, 1/8″, 1/4″) for compatibility with die grinders, rotary tools, flexible shafts, and CNC machines.

- Consistent Quality: Manufactured under strict quality control protocols, ensuring reliable performance batch after batch – essential for continuous production lines.

Wide Range of Applications:

These electroplated diamond rotary burrs and mounted points are indispensable tools across various industries for tasks including:

- Grinding & Shaping: Hardened steel dies, molds, carbide components.

- Deburring & Edge Breaking: Removing sharp edges from machined or cast parts made of hard materials.

- Internal Grinding: Finishing holes or internal features in ceramics, glass, or carbide.

- Carving & Engraving: Detailed work on stone, glass, and other hard non-metals.

- Material Removal: Efficient stock removal in hard-to-reach areas.

Ideal Materials:

- Cemented Carbide (Tungsten Carbide)

- Hardened Steels (HSS, Tool Steels)

- Ceramics (Alumina, Zirconia)

- Glass & Quartz

- Stone & Granite

- Fiberglass & Composites

- Ferrite & Other Hard Non-Metallic Materials

Reliable Supply & Customization Services:

We are committed to being your reliable diamond tool supplier, ensuring consistent product quality for dependable performance.

In addition to our standard products, we offer custom manufacturing services. We can produce electroplated diamond mounted points / burrs tailored to your specific application, including customization of:

- Unique head shapes and profiles.

- Non-standard shank dimensions or materials.

- Specific diamond grit sizes and concentrations.

- Special bond characteristics.

Please get in touch to discuss your specific requirements for standard models or custom tooling needs.