-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

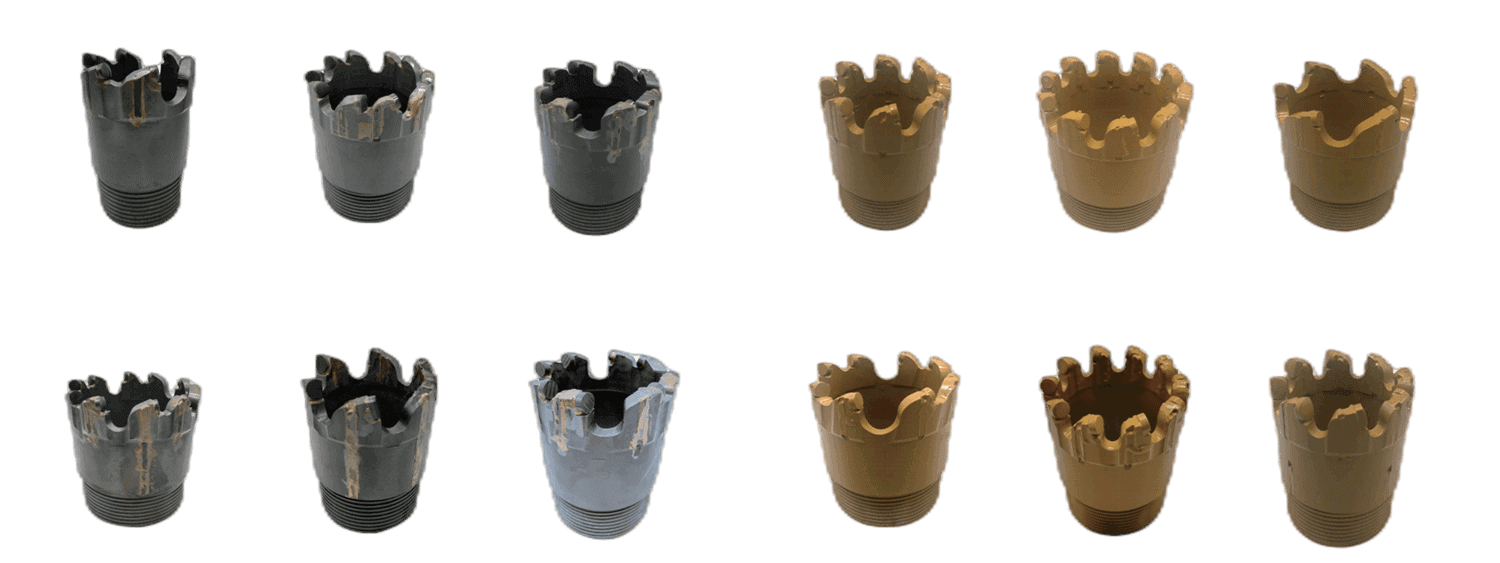

Different Shape PDC Coring Bits

Achieve durable, precise core sampling with customizable PDC Bits. Feature premium PDC cutters and robust construction in diverse shapes and sizes for geological/engineering needs.

Customizable PDC Core Bits: Precision Sampling Across Diverse Conditions

Engineered for dependable core recovery in geological exploration, geotechnical engineering, and related drilling projects, these Polycrystalline Diamond Compact (PDC) Core Bits merge high-performance materials with meticulous manufacturing. They offer a versatile and adaptable solution, delivering reliable sampling results even in challenging conditions through extensive customization possibilities.

Built for Durability: Premium Materials and Advanced Processes

The longevity and robustness of these core bits stem from a foundation of superior materials and carefully controlled production techniques:

- Top-Grade PDC Cutters: We select first-class Polycrystalline Diamond Compact cutters sourced from leading manufacturers. These cutters are chosen for their high abrasion resistance, thermal stability, and sharp cutting edges, ensuring efficient rock penetration and extended operational life, particularly effective in soft to medium-hard rock formations.

- High-Integrity Steel Bodies: Each bit body is precision-machined from high-quality special steel that has undergone rigorous testing for density and hardness. This guarantees exceptional toughness, resilience against operational stress, and resistance to fatigue failure during demanding drilling cycles.

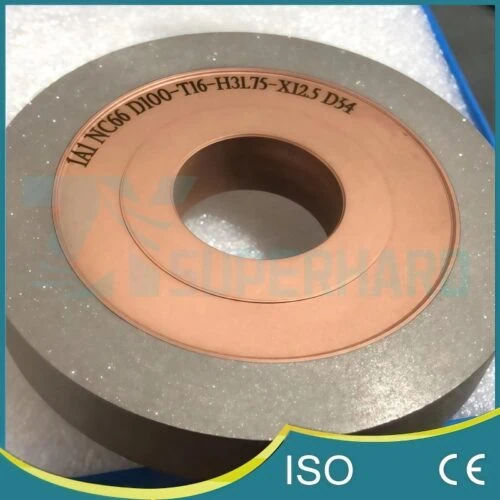

- Specialized Treatments & Bonding: To maximize performance and lifespan, the steel bodies receive specialized treatments including chemical immersion, thorough derusting, and multi-stage grinding for an optimal surface finish. Crucially, the PDC cutters are affixed using advanced silver soldering methods. This technique creates an exceptionally strong bond, preventing cutter detachment under high torque and impact, while also safeguarding the cutters’ structural integrity from excessive heat during the bonding process.

Precision Engineering for Enhanced Performance

Exact manufacturing tolerances and thoughtful design translate directly into superior downhole performance:

- High-Accuracy Machining Capability: We have the validated capability to machine critical bit dimensions and intricate features, such as cutter spacing and orientation, to exceptionally tight tolerances (±0.02mm where required by the design). This geometric consistency ensures predictable drilling behavior, accurate borehole sizing, and optimal interaction with the formation.

- Secure & Efficient Connections: Precision-lathed threads ensure a tight, stable, and perfectly aligned connection between the core bit, core barrel, and drill string. This minimizes power loss through the drill train, reduces harmful vibrations that can affect core quality and tool life, and prevents connection failures in the borehole.

Versatility Through Comprehensive Customization

Recognizing that standard solutions don’t always suffice, we specialize in tailoring PDC core bits to meet specific challenges:

- Standard Size Range: A comprehensive range of standard core sizes are readily available, including 65mm, 75mm, 91mm, 113mm, 130mm, 153mm, 171mm, 200mm, and 219mm, covering many common application needs.

- Tailored Designs: Beyond standard sizes, we excel at creating fully customized solutions. This includes manufacturing bits with diverse shapes and profiles (like the specialized Crowns Shape for enhanced stability or unique flushing characteristics), application-specific body geometries, optimized PDC cutter layouts, tailored flushing port designs, and any required thread type. Our goal is to provide a tool perfectly matched to your geological conditions and project objectives.

Proven Application Areas

These versatile PDC core bits are successfully utilized in a variety of sectors requiring reliable core samples:

- Geological exploration and resource evaluation

- Geotechnical site investigation for civil engineering, construction, and infrastructure development

- Mineral prospecting and mine planning

- Environmental assessment and monitoring well drilling

Leverage our expertise. Contact our technical sales team to discuss your application and collaboratively design the optimal customized PDC core bit solution for your project’s success.