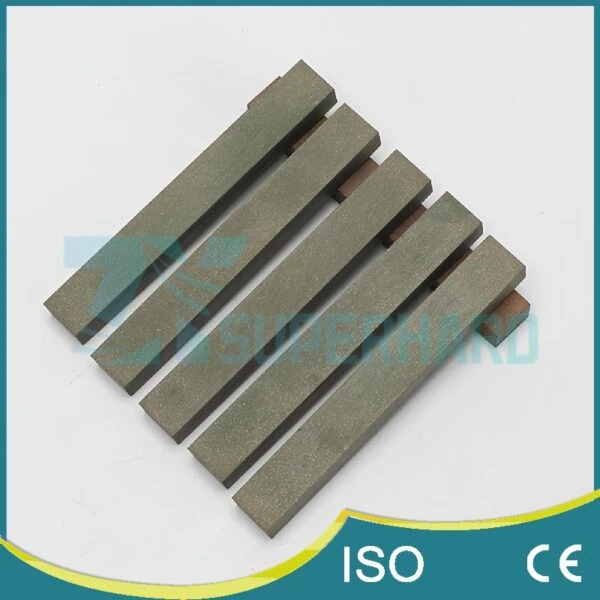

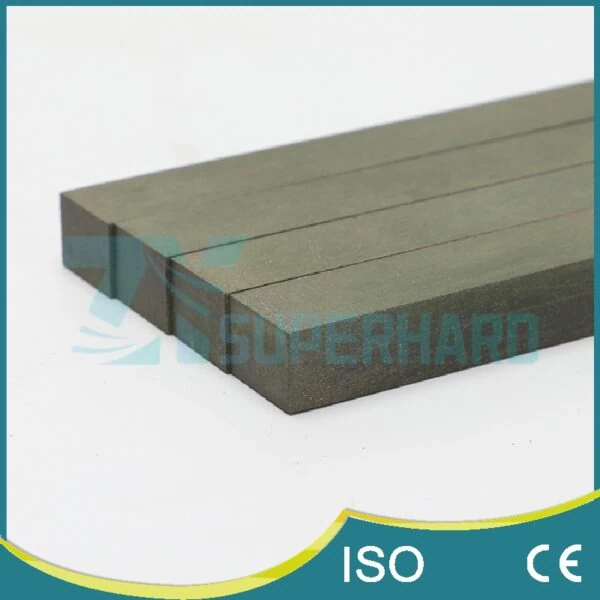

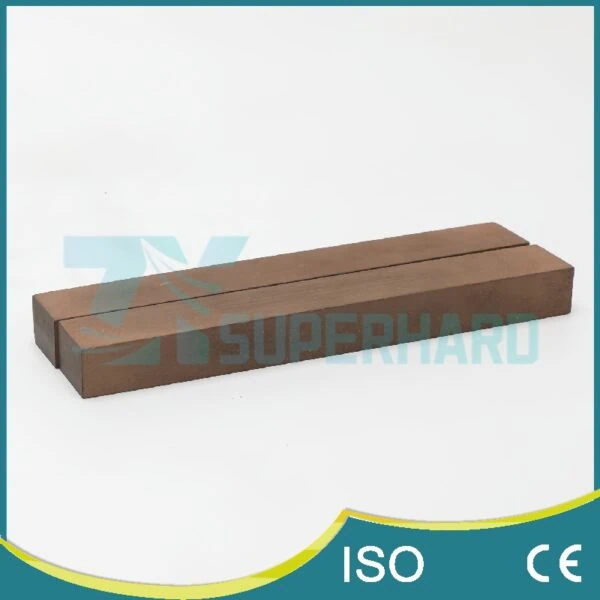

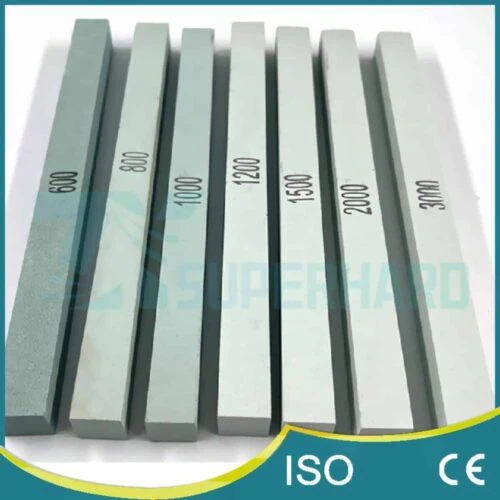

Our Diamond Oil Honing Stones are engineered for the most demanding finishing applications where precision, speed, and surface quality are paramount. Manufactured with high-concentration, top-grade monocrystalline or polycrystalline diamond particles, these honing sticks are expertly bonded to a rigid substrate, delivering unparalleled performance on the hardest and most abrasive materials.

Key Features & Benefits:

- Exceptional Cutting Performance: The inherent hardness of diamond allows for aggressive material removal and significantly faster honing cycles compared to conventional abrasives like silicon carbide or aluminum oxide. This boosts productivity and reduces cycle times.

- Superior Durability and Longevity: Featuring outstanding wear resistance, our diamond honing stones maintain their shape and cutting effectiveness for an extended period, leading to lower tool costs and less frequent replacement.

- Outstanding Surface Finish: These stones produce a consistent, uniform scratch pattern, capable of achieving excellent surface finishes (low Ra values) and precise geometric tolerances, critical for high-performance components.

- Versatility Across Materials: Engineered to excel where traditional abrasives fail, they are ideal for honing, deburring, and polishing a wide range of challenging materials, including:

- Tungsten Carbide and Cermets

- Technical Ceramics (e.g., Alumina, Zirconia)

- Optical Glass and Sapphire

- Non-Ferrous Metals (e.g., high-silicon aluminum)

- Heat-Resistant Superalloys

Applications:

Our diamond honing stones are trusted by professionals in various industries for critical applications:

- Mold and Die: Polishing and finishing complex mold cavities and die surfaces.

- Automotive & Aerospace: Honing cylinder bores with specific coatings (e.g., Nikasil, Alusil) or made from high-silicon aluminum alloys; finishing components for fuel injectors and hydraulic systems.

- Cutting Tools: Sharpening and refining the cutting edges of carbide or HSS tools.

- General Machining: Deburring sharp edges, finishing bores, and lapping flat surfaces with precision.

Technical Specifications:

- Abrasive Material: High-Grade Monocrystalline or Polycrystalline Diamond

- Grit Sizes: A comprehensive range is available, from coarse grits for rapid stock removal (e.g., 100# / D151) to ultra-fine grits for mirror polishing (e.g., 3000# / D5).

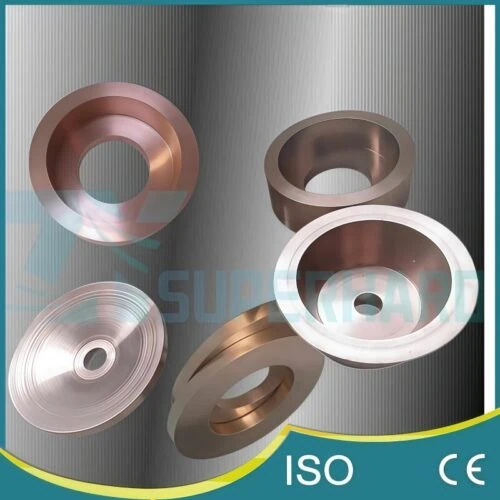

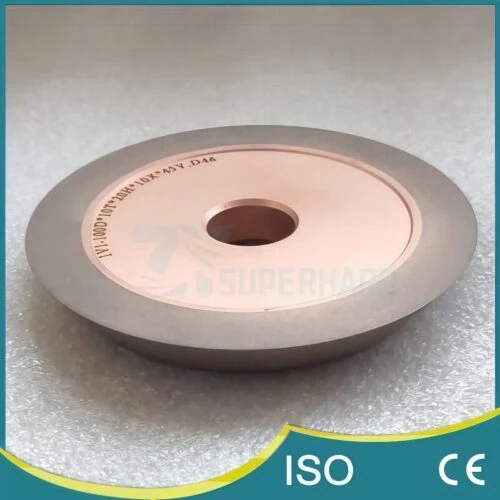

- Bond Type: A full range of bond systems are available to suit your application, including high-strength Metal, fine-finishing Resin, versatile Vitrified, and aggressive Electroplated bonds.

- Standard Dimensions: Available in a variety of standard square, rectangular, and triangular cross-sections. (e.g., 3x6x100mm, 6x12x150mm, etc.)

- Lubrication: Recommended for use with a high-quality honing oil to lubricate, cool the workpiece, and flush away swarf for optimal results and extended tool life.

Customization Services:

We understand that standard sizes do not fit every job. We offer a comprehensive customization service to meet your unique application needs. We can tailor the following specifications:

- Custom Grit Sizes and Concentrations

- Non-Standard Dimensions (Length, Width, Height)

- Special Shapes and Profiles

- Specific Bond Formulations

Contact us today with your technical drawings or requirements, and our engineering team will work with you to create the perfect diamond honing solution for your project.