-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

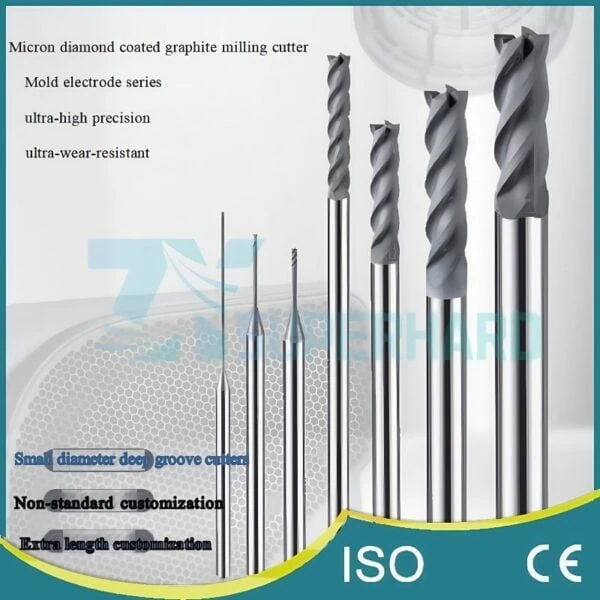

Diamond Coated Graphite Standard Milling Cutter

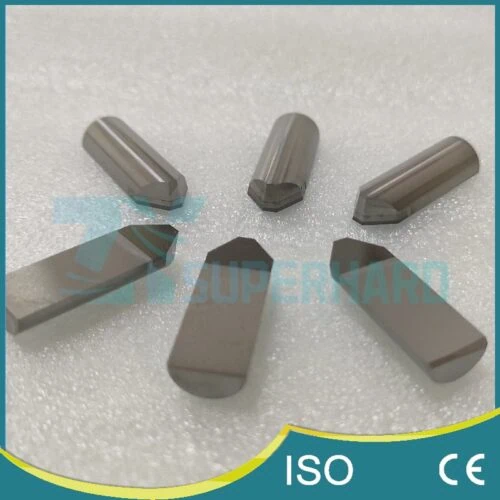

Diamond-coated milling cutter specifically designed for machining graphite. Also excels on composites & aluminum alloys, offering 50-100x tool life over carbide.

Tired of rapid tool wear and frequent replacements when machining abrasive materials like graphite, composites, or high-silicon aluminum? ZYsuperhard’s Diamond Coated Standard Milling Cutters are engineered as the high-performance solution. By applying an ultra-hard, low-friction diamond coating to a precision solid carbide end mill body, these tools deliver exceptional durability, dramatically extended lifespan, and superior machining performance, making them ideal for your most demanding applications on these challenging materials.

Key Applications:

- Machining Graphite: Ideal for high-speed milling of graphite electrodes, molds, fixtures, and other graphite components, providing exceptional wear resistance and surface finish.

- Non-Ferrous Metals: High-efficiency cutting of aluminum alloys (including high-silicon types), copper, brass, and other ductile non-ferrous metals where long tool life is required.

- Composite Materials: Precise machining of abrasive composites such as carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP).

- Automotive & Aerospace Industries: Widely utilized for machining aluminum alloys and composite components requiring long tool life and high precision within these sectors.

- Wood Processing: Excellent performance on abrasive wood composites like MDF, HDF, particleboard, and laminates.

Advantages:

- Extended Tool Life: Lasts 50 to 100 times longer than conventional uncoated cemented carbide tools due to the extreme hardness (approaching natural diamond) and superior abrasion resistance of the diamond coating.

- Cost Efficiency: Significantly reduces overall production costs through enhanced durability, resulting in far fewer tool changes, less machine downtime, and reduced tooling inventory.

- High Performance: Excels in high-speed machining (HSM), operates effectively at higher temperatures, and thrives in abrasive conditions thanks to the coating’s exceptional thermal stability and unparalleled wear resistance.

- Versatility: Highly effective on materials that challenge traditional tools due to being sticky (like aluminum, copper) or causing ‘fuzziness’ (like composites), as the ultra-smooth, hard, and low-friction diamond coating minimizes material adhesion (BUE) and maintains a sharp edge for cleaner cuts.

Available Types:

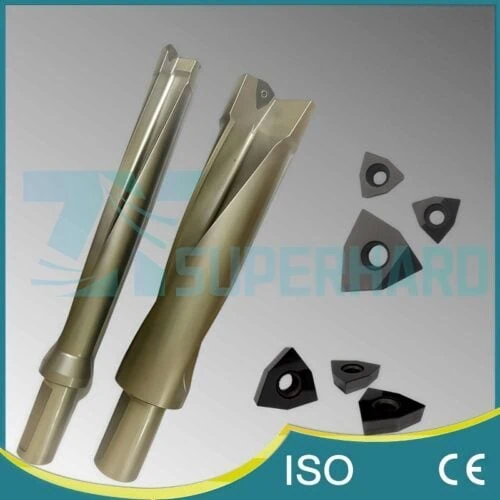

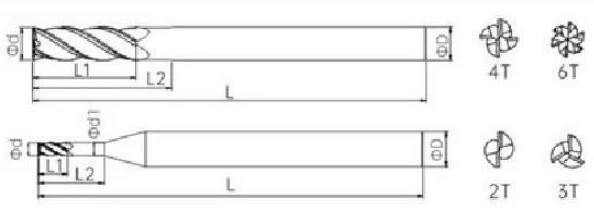

ZY SUPER HARD offers three distinct types of diamond-coated milling cutters to suit various machining needs:

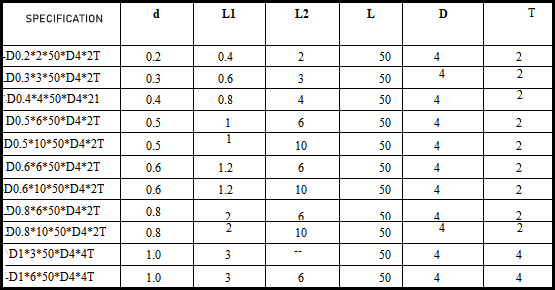

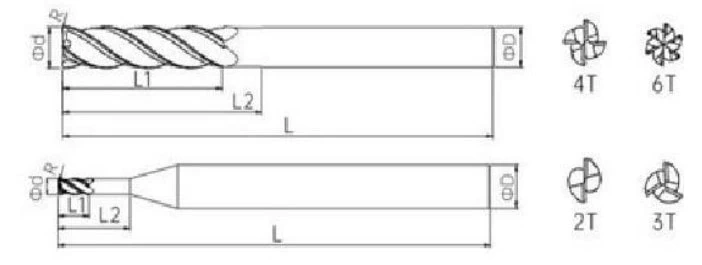

1.Flat Bottom Tool Type: Ideal for precise flat surface milling. Standard specifications available; customization options offered.

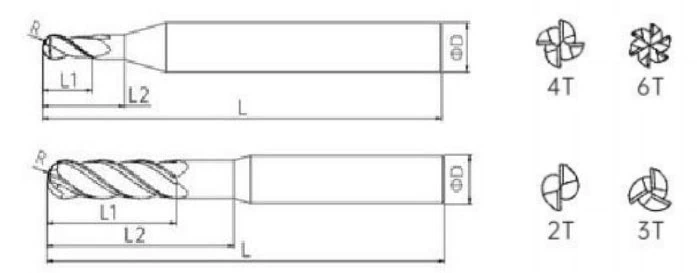

2.Round Nose Tool Type: Perfect for contouring and profiling tasks.

3.Ball Tool Type: Designed for 3D machining and creating spherical surfaces.

Whether you are machining intricate graphite electrodes, large composite panels, high-volume aluminum parts, or abrasive wood components, these diamond-coated cutters offer a robust, reliable, and highly economical machining solution.

Customization:

If our standard offerings do not meet your specific requirements, our expert sales team is here to help. We provide tailored solutions to match your unique needs. Contact us today, and we will respond within 24 hours.