-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

PCD Countersink Drill for CFRP,GFRP Composite Materials

PCD countersink drill for composites, Al, Ti & ceramics. Durable PCD edge, precision thread-cone fit ensure long life (+200% vs peers) & accurate bit changes. 90°-130° angles. Custom for aerospace/defense.

High-Precision PCD Countersink Drills for Composites, Aluminum, Titanium & Ceramics

Achieve clean, accurate, and damage-free countersinks in today’s most challenging aerospace, automotive, and industrial materials with ZYsuperhard’s specialized PCD Countersink Drills (also known as countersink cutters). Machining advanced materials like Carbon Fiber Reinforced Polymers (CFRP), Glass Fiber Reinforced Polymers (GFRP), aluminum alloys, titanium alloys, and ceramics often presents difficulties such as fiber tear-out, delamination, burrs, and rapid tool wear when using conventional countersinking tools. Our PCD countersinks are meticulously engineered to overcome these specific challenges, delivering superior hole quality, process reliability, and exceptional tool life.

Key Features and Performance Advantages:

- Durable PCD Cutting Edge: Leveraging the extreme hardness and abrasion resistance of Polycrystalline Diamond, the cutting edges cleanly shear through abrasive composite fibers and effectively machine metals like aluminum and ceramics. This results in significantly extended tool life (potentially achieving up to 200% longer life compared to comparable carbide or competing tools in specific high-wear applications) and maintains crucial edge sharpness for consistent, high-quality results. Note: For Titanium Alloys, optimal performance requires specific PCD grades and carefully selected cutting parameters due to potential chemical reactivity at high temperatures.

- High-Precision Thread-Cone Fit Interface: This advanced mounting system (where applicable on modular designs) ensures a highly accurate, rigid, and repeatable connection between the countersink cutting head and the tool body or guide mechanism. It guarantees excellent concentricity relative to the pilot hole and allows for simple, precise, and rapid replacement of worn cutting heads, minimizing setup adjustments and machine downtime.

- Optimized Geometry for Defect-Free Holes: Designed with specific cutting angles and edge preparations to produce precise countersink forms (standard angles include 90°, 99.5°, 100°, 119.5°, 120°, 130°) while actively minimizing common composite machining defects like exit burrs, fiber pull-out, and delamination. This ensures high-integrity holes suitable for critical fastener installations in aerospace and defense applications.

- Enhanced Durability (Including Guide Elements): The robust design potentially extends to integrated guide columns or pilots (please confirm specific tool structure if applicable), contributing to the overall longevity and stability of the tooling system.

Target Materials & Primary Applications:

Ideal for producing high-quality, precise countersinks for fasteners (rivets, screws) in demanding materials:

- Composite Materials (CFRP/GFRP): Creating clean, defect-free countersunk holes in panels, structures, and components widely used in Aerospace, Defense, Automotive (lightweighting), and Wind Power industries without damaging the material integrity.

- Aluminum Alloys: High-speed, precision countersinking in various wrought and cast aluminum alloys utilized across multiple sectors.

- Titanium Alloys: Suitable for specific countersinking applications in Aerospace and Medical fields, requiring optimized process parameters.

- Ceramics: Machining precise countersinks in technical ceramic components where hardness and wear resistance are needed.

Specifications & Customization:

- Standard Angles: Available for common countersink angles including 90°, 99.5°, 100°, 119.5°, 120°, and 130°.

- Customization: ZYsuperhard readily accepts non-standard product requirements based on customer drawings and specifications. Custom angles, diameters, multi-step features, pilot configurations, shank types, and specific PCD grades can be engineered to create the optimal solution for your unique application.

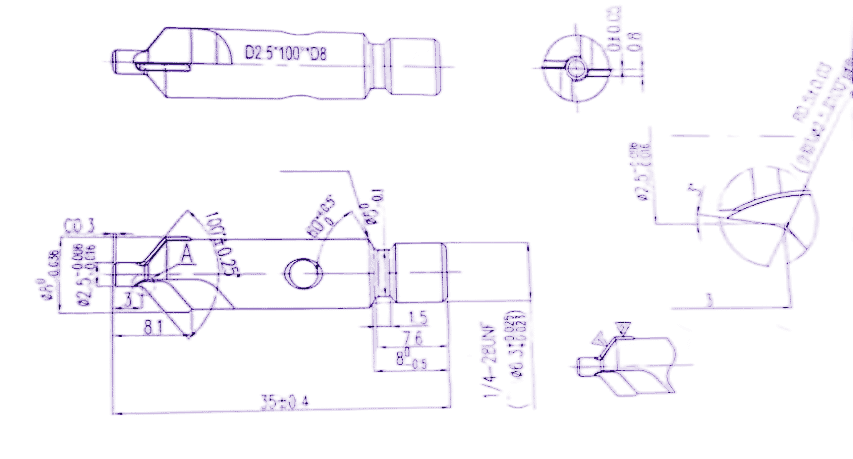

Example Drawing:

Choose ZYsuperhard PCD Countersink Drills for superior quality, significantly extended tool life, and enhanced process reliability when producing critical countersinks in advanced aerospace and industrial materials. Contact us to discuss your specific requirements and challenges.