-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

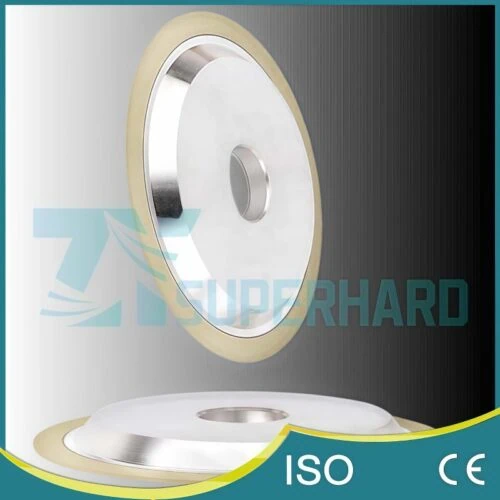

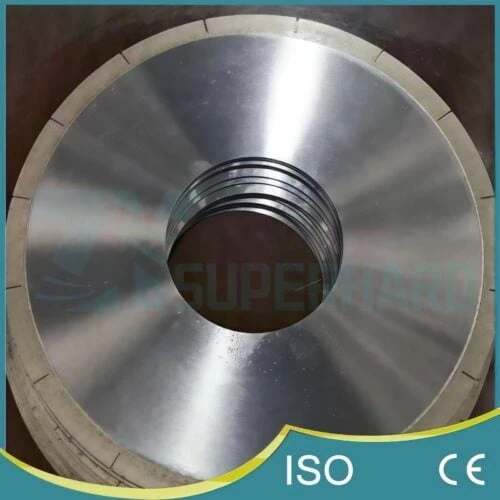

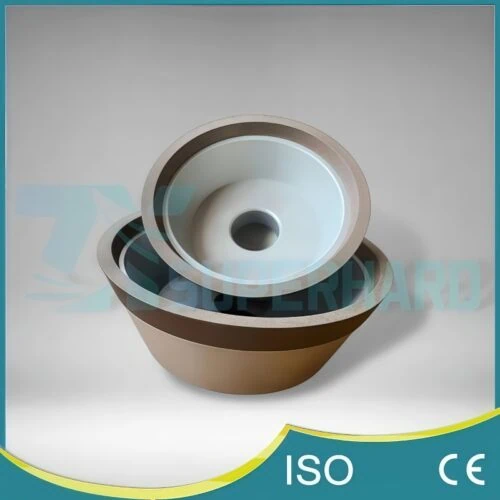

6V5 CNC High Precision Grinding Wheels

Achieve superior accuracy on CNC tool grinders. 6V5 hybrid bond wheels excel on ball noses, R cutters & complex angles. Offers optimal balance of removal rate, finish, and form holding.

High-Precision 6V5 Hybrid Bond Wheels for CNC Tool Grinding

Engineered for the demands of modern CNC tool grinding, ZYsuperhard’s 6V5 hybrid bond grinding wheels deliver exceptional precision and efficiency for manufacturing and resharpening complex cutting tools. This wheel shape and advanced bond technology are specifically optimized for creating intricate geometries like radii, ball noses, and clearance angles with superior accuracy and surface finish on today’s leading CNC tool grinders.

The Hybrid Bond Advantage:

Our advanced hybrid bond system represents a significant step forward in grinding technology. It synergistically combines the benefits of different bond types to offer a unique balance ideal for tool grinding:

- Balanced Performance: Achieves an optimal equilibrium between efficient material removal rates (approaching resin or metal bond capabilities) and excellent form holding with fine surface finishes (rivaling vitrified bonds).

- Enhanced Efficiency on CNC Grinders: The bond characteristics ensure consistent cutting performance across complex multi-axis grinding paths, often leading to longer dressing intervals and reduced non-productive time compared to traditional bonds.

- Cooler Grinding Action: Formulated to minimize heat generation during grinding, protecting heat-sensitive tool materials like Tungsten Carbide and High-Speed Steel (HSS) from thermal damage and preserving edge integrity.

Key Features:

- Optimized 6V5 Shape: The industry-standard 6V5 dish wheel profile provides excellent clearance and accessibility for grinding primary and secondary relief angles, corner radii (R cutters), ball nose forms, and other complex profiles on tool ends and peripheries.

- Premium Superabrasives: Select from high-quality Diamond (D) grits (available in sizes such as D25, D35, D46, D64, D76) for grinding Tungsten Carbide tools, or high-performance CBN (B) grits (available in sizes such as B30, B46, B91) for High-Speed Steel (HSS), hardened tool steels, and other ferrous materials. Precise micron grading ensures optimal finish and edge quality control.

- High Geometric Accuracy: Our wheels are manufactured to tight tolerances for runout, balance, and dimensional accuracy, ensuring stable, vibration-free, and precise performance on your CNC grinder setup.

Core Application Areas:

These 6V5 hybrid wheels excel in the demanding production and regrinding processes for a wide range of cutting tools:

- End Mills: Precision grinding of complex end geometries including ball noses, corner radii (R cutters), chamfers, variable helix and pitch features, as well as peripheral grinding of primary and secondary clearance angles (relief).

- Drills & Reamers: Accurately grinding point geometries, facets, clearance angles, step features, and gashings.

- Form Tools & Inserts: Creating or resharpening custom profile cutting tools and inserts where high geometric fidelity and edge quality are paramount.

- Clearance Angle Grinding: Ideal for generating precise primary and secondary relief angles (arc back angles) on various types of cutting tools to ensure proper cutting action and clearance.

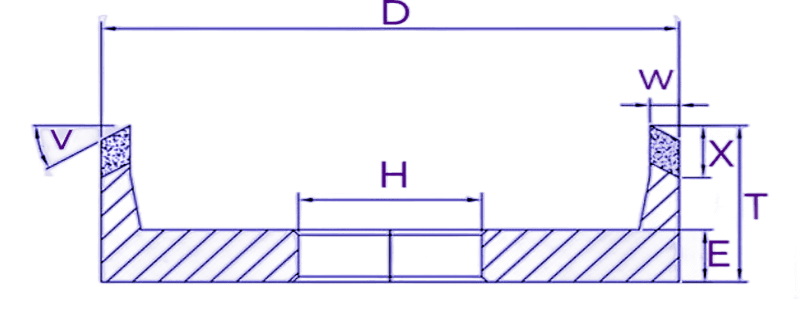

Drawing:

Specification:

| D (mm) | T (mm) | X (mm) | H (mm) | V |

|---|---|---|---|---|

| 75 | 20/25/30/32/35/40 | 3-10 | 20, 31.75, 32 | 30°-75° |

| 100 | 20/25/30/32/35/40 | 3-10 | 20, 31.75, 32 | |

| 125 | 20/25/30/32/35/40 | 6-10 | 20, 31.75, 32 | |

| 150 | 20/25/30/32/35/40 | 6-15 | 20, 31.75, 32 | |

| 200 | 20/25/30/32/35/40 | 6-15 | 20, 31.75, 32 |

Customization:

Beyond the specifications potentially shown in the table, we offer fully customized 6V5 hybrid bond wheels. We can tailor the diameter, thickness, bore size, abrasive type (Diamond/CBN), specific grit size, concentration, and even fine-tune the hybrid bond characteristics to perfectly match your CNC machine capabilities, target tool material, coolant type, and specific application requirements. Please contact us to discuss your unique custom needs.

Benefits Summary:

- Delivers superior geometric accuracy on complex tool profiles and features.

- Produces excellent cutting edge quality and surface finish for optimal tool performance.

- Provides an optimized balance of grinding efficiency (material removal rate) and wheel life/form holding.

- Ensures reliable and consistent performance shift after shift on demanding CNC tool grinding machines.

- Often reduces the need for frequent in-process dressing compared to conventional bonds.

Choose ZYsuperhard 6V5 hybrid wheels for predictable, high-quality results and enhanced productivity in your CNC tool grinding operations.