-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

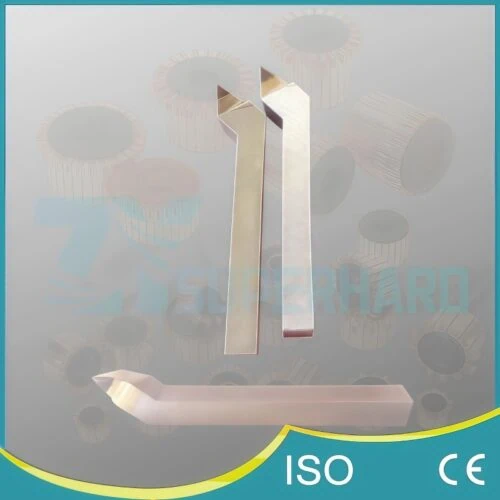

4 Flute PCD Milling Cutters

Custom 4-flute PCD milling cutter with internal cooling for precision die-cast aluminum machining. Delivers extended tool life and superior performance.

High-Performance 4 Flute PCD Milling Cutter for Die-Cast Aluminum

Engineered for superior performance and extended tool life in demanding high-precision machining of die-cast aluminum, this 4 Flute PCD Milling Cutter from ZYsuperhard is the optimal choice for critical applications in industries like Automotive and Electronics. By combining the extreme hardness and wear resistance of Polycrystalline Diamond (PCD) cutting edges with advanced tool design features like a rigid solid carbide body and internal cooling, it delivers consistent part quality and significantly reduced tooling costs.

Advanced Design for Optimal Results:

- Premium PCD Cutting Edges: Featuring precisely brazed, high-quality PCD tips, this cutter offers dramatically longer tool life – potentially many times that of traditional solid carbide end mills – when machining abrasive die-cast aluminum alloys. The PCD maintains exceptionally sharp cutting edges far longer, directly contributing to superior surface finishes and reliable dimensional accuracy throughout extended production runs.

- Solid Carbide Body: The robust solid carbide body provides maximum rigidity and minimizes vibration. This inherent stability is crucial for achieving the tight tolerances required in precision manufacturing and enables the higher cutting speeds often utilized with PCD tooling without compromising accuracy or finish.

- Optimized 4 Flute Geometry: The four-flute design provides an effective balance between smooth cutting action, adequate chip evacuation, and the ability to achieve fine surface finishes. This makes it highly suitable for both semi-finishing and finishing operations on die-cast aluminum components where quality is paramount.

- Integrated Internal Cooling: Equipped with precisely engineered internal coolant channels, this cutter delivers coolant directly to the heart of the cutting zone. This targeted cooling effectively controls heat buildup at the cutting edge, efficiently flushes chips away, prevents common issues like material adhesion (BUE) with aluminum, and ultimately allows for significantly higher, more productive cutting speeds and feed rates, while further enhancing the already impressive tool life of PCD.

Application Focus: Die-Cast Aluminum Excellence:

This tool is specifically engineered and optimized to overcome the unique challenges presented by machining die-cast aluminum alloys, materials used extensively in:

- Automotive Industry: For producing engine parts (blocks, heads), transmission housings, valve bodies, covers, structural components, and more that require precision milling and excellent surface integrity.

- Electronic Industry: Manufacturing device enclosures, complex heat sinks, communication equipment chassis, and other aluminum parts demanding both high dimensional accuracy and superior surface aesthetics.

Achieve consistently superior results, minimize costly burr formation, and maximize your production throughput with a cutting tool expertly designed for this specific material group.

Customization for Your Specific Needs:

While this configuration represents a highly effective tool for many applications, we understand that unique machining tasks often require tailored solutions. ZYsuperhard specializes in providing custom PCD milling cutters. If you need specific dimensions (diameter, length, corner radius), non-standard geometries, particular tolerances, or other modifications based on your drawings and unique application requirements, our engineering team is ready to collaborate with you. We are committed to developing the perfect PCD milling solution to help you overcome your specific manufacturing challenges.

Contact us to discuss your die-cast aluminum machining application or to request a quote for a custom PCD milling cutter.