-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

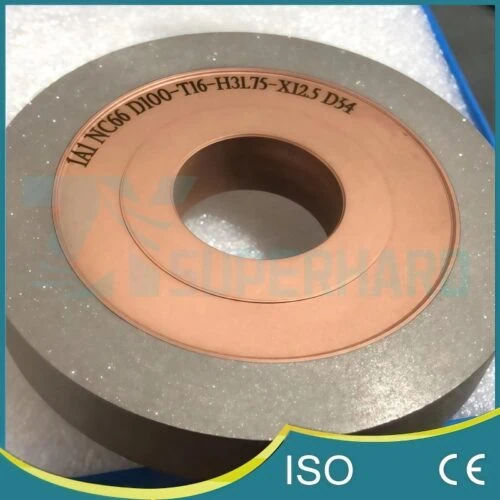

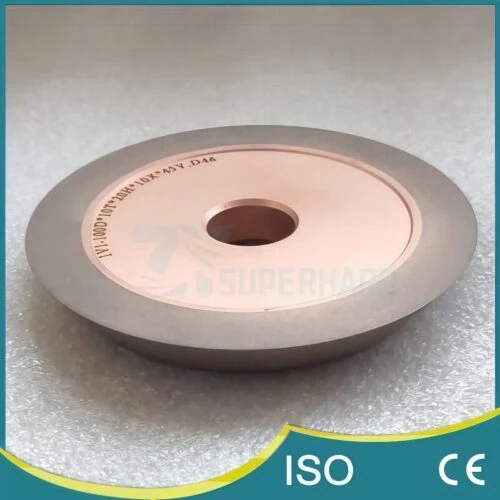

3A1 Type Vitrified Bond Diamond Grinding Wheels

High-speed 3A1 vitrified diamond wheels for grinding TC, Ceramics & PCD. Ideal for conical/surface grinding on Junker/Studer machines. Delivers precision, efficiency & long life. Custom specs.

High-Speed 3A1 Vitrified Bond Diamond Wheels for Grinding Carbide, Ceramics & PCD

Maximize productivity and achieve unparalleled precision when grinding ultra-hard materials with ZYsuperhard’s 3A1 Vitrified Bond Diamond Grinding Wheels. Specifically engineered for demanding High-Speed Grinding (HSG) operations (suitable for peripheral speeds potentially exceeding conventional limits), these wheels excel in processing Tungsten Carbide, technical ceramics, and Polycrystalline Diamond (PCD/PCBN) materials on high-performance grinding machines such as Junker, Reinecker, and Studer. The versatile 3A1 dish shape makes them ideal for cylindrical, conical, profile, and flat surface grinding applications where specific wheel access or engagement is necessary.

The Vitrified Bond Diamond Advantage for HSG on Hard Materials:

This advanced wheel technology is critical for success in high-speed grinding of these challenging materials:

- Vitrified Bond Rigidity & Thermal Stability: Our high-strength ceramic bond provides exceptional rigidity and is stable at high temperatures, essential characteristics for withstanding the significant stresses and heat generated during High-Speed Grinding. This minimizes wheel deflection, enabling superior geometric accuracy and excellent form holding capabilities for consistent part quality even at aggressive removal rates.

- Optimized Porosity for Cool Cutting & Chip Removal: The engineered porous structure of the vitrified bond ensures highly efficient penetration and transport of coolant directly into the grinding zone, while also facilitating rapid removal of grinding swarf. This promotes cool cutting action, crucial for preventing thermal damage or micro-cracking in sensitive materials like ceramics and PCD/PCBN, and prevents wheel loading for sustained performance.

- Premium Diamond for Ultra-Hard Materials: High-quality diamond abrasive provides the necessary hardness, sharpness, and wear resistance to effectively and efficiently cut extremely hard materials like Tungsten Carbide, Ceramics, and PCD/PCBN, ensuring both high material removal rates and extended wheel life.

Key Features:

- Engineered for High-Speed Operation: Designed, manufactured, and balanced for safe, stable, and productive performance at the high peripheral speeds characteristic of HSG processes.

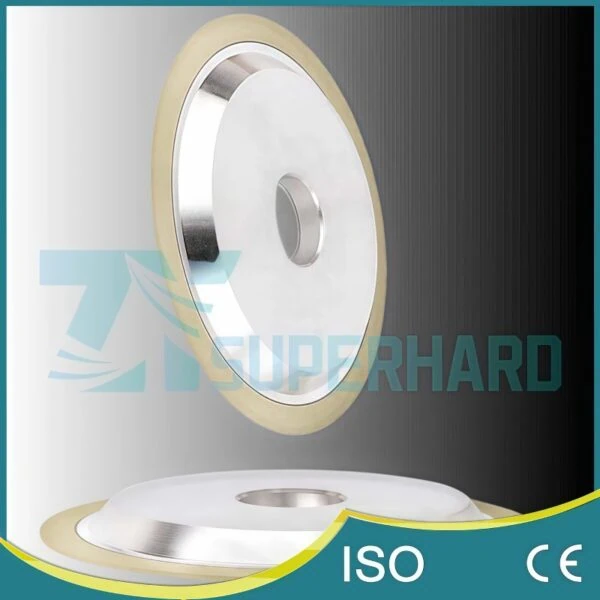

- Versatile 3A1 Dish Wheel Shape: The ISO Type 3A1 profile provides necessary clearance and is adaptable for grinding conical surfaces, shoulders, specific profiles, relief angles, and flat surfaces using the wheel rim on appropriate CNC or universal grinding setups.

- Fine Grit Options for Precision Finishing: Available in fine diamond grits such as D64 (approx. 230/270 mesh) and D91 (approx. 170/200 mesh), as well as other customizable grits, ideal for achieving high surface finishes and precise edge quality on demanding components.

- Proven Machine Compatibility: Optimized for use and proven performance on high-precision grinding machines renowned for HSG capabilities, including specific models from Junker, Reinecker, Studer, and similar advanced grinding platforms.

Core Applications:

Ideal for high-speed precision grinding operations on components made from Tungsten Carbide, Technical Ceramics, and PCD/PCBN materials:

- Cutting Tools (Carbide, PCD/PCBN): Grinding specific clearance angles, relief surfaces, conical points, or profile features on cutting tools where the 3A1 shape provides optimal access or geometry generation.

- Wear Parts (Carbide, Ceramic): Precision grinding of cylindrical, conical, or flat surfaces on extremely hard wear components like seals, nozzles, plungers, guides, etc.

- Ceramic Components: High-precision grinding of technical ceramic parts used in electronics, medical devices, aerospace, or other industries requiring tight tolerances and fine finishes.

- PCD/PCBN Segment Processing: Grinding operations involved in the manufacturing, shaping, or preparation of PCD or PCBN tool segments.

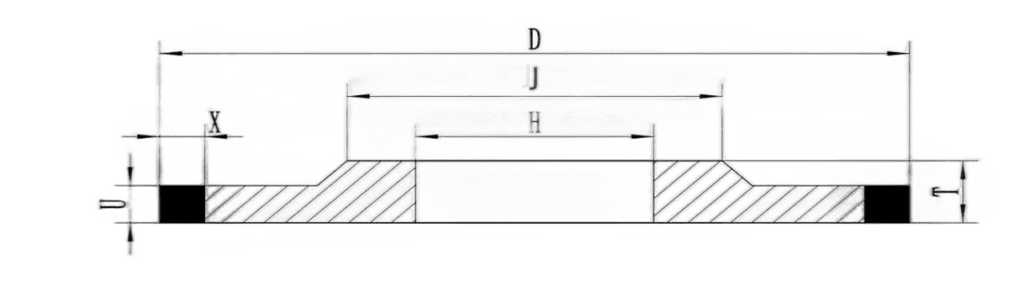

3A1 Drawing

3A1 Specification (MM)

| D (Diameter) | T (Thickness) | H (Hole) | U (Rim Width) | X (Abrasive Depth) |

|---|---|---|---|---|

| 150-500 | 5-150 | 18-203 | 3-10 | 6-10 |

Note: Other specifications can be customized upon request!

Grit Examples:

Diamond Grits such as D64, D91 available (other grits customizable based on request). Selection typically depends on the workpiece material, stock removal required, and desired surface finish.

Customization:

ZYsuperhard specializes in customized 3A1 vitrified bond diamond wheels tailored for your specific High-Speed Grinding (HSG) machine, target material (Carbide, Ceramic, PCD variants), component geometry, and performance objectives (e.g., maximizing removal rate vs. achieving ultra-fine finish). We can customize all dimensions, grit size, diamond concentration, and bond characteristics.

Choose ZYsuperhard 3A1 Vitrified Diamond Wheels for reliable, high-performance, high-speed grinding that delivers exceptional precision and efficiency on your most challenging hard materials. Contact us to discuss your specific HSG application needs.