-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

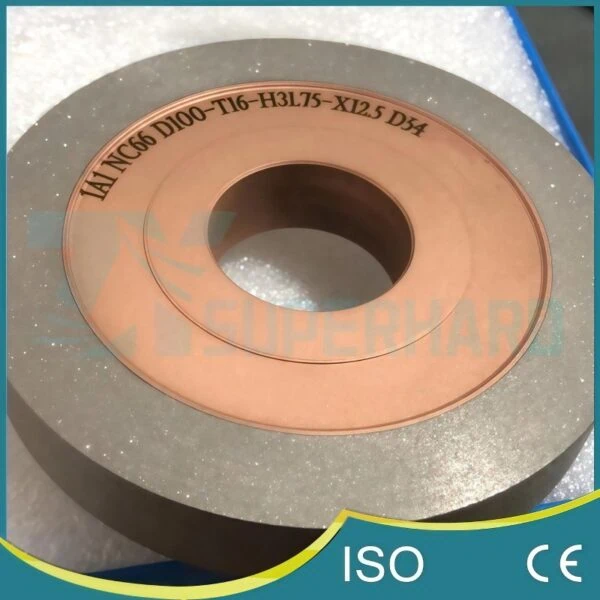

1A1 Hybrid Bond Diamond / CBN Slotting Grinding Wheels

1A1 hybrid bond Diamond/CBN wheels for precision slotting on CNC grinders (Walter, Anca). Unique bond offers balanced performance: high efficiency, good finish, & long life. Custom specs.

1A1 Hybrid Bond Diamond & CBN Slotting Grinding Wheels

Elevate your precision slotting operations on high-end CNC tool grinders with these advanced 1A1 Hybrid Bond Grinding Wheels from ZYsuperhard. Specifically engineered for demanding applications on machines like Walter, ANCA, and EWAG, and available with either Diamond or CBN abrasives, these wheels leverage a unique hybrid bond system. This innovative bond delivers an optimized balance of grinding efficiency, edge quality retention, and extended wheel life, ideal for creating precise slots and grooves in cutting tools and other components.

The Hybrid Bond Advantage for Precision CNC Slotting

Hybrid bond technology represents a significant step forward, strategically blending the properties of different bonding agents (often combining elements of resin, metal, and/or ceramic systems) to excel where traditional single-bond wheels may compromise:

- Balanced Performance Profile: Designed to uniquely combine desirable characteristics – potentially the high material removal rates and sharpness associated with resin bonds, alongside the enhanced durability, heat resistance, and form-holding capabilities closer to metal or vitrified bonds.

- High Grinding Efficiency & Quality: Enables efficient slotting cycles while maintaining excellent surface quality on the flanks and bottom of the groove, critical for tool performance (e.g., chip flow in flutes).

- Superior Edge Quality & Form Holding: Produces sharp, well-defined slot edges on the workpiece and crucially maintains the grinding wheel’s thin profile integrity for longer durations, ensuring consistent slot dimensions.

- Potentially Extended Dressing Intervals: The optimized wear behavior of the hybrid bond can lead to longer periods between wheel dressing or conditioning, maximizing valuable machine uptime.

Abrasive Selection: Diamond or CBN for Your Material

Choose the appropriate superabrasive for the material being slotted:

- Diamond Hybrid Bond Wheels: The optimal choice for slotting cemented carbide (tungsten carbide), technical ceramics, glass, graphite, composites, and other hard, brittle non-metallic or non-ferrous materials commonly used in cutting tools or wear parts.

- CBN Hybrid Bond Wheels: Essential for slotting hardened steels (HSS, tool steels, die steels >HRC 50), cast irons, and certain high-temperature alloys, where CBN’s superior thermal and chemical stability prevents degradation when grinding ferrous materials.

Specifications and CNC Machine Compatibility

These hybrid bond wheels are specifically adapted and proven for high-performance slotting on leading 5-axis CNC grinding machines, including models from Walter, ANCA, EWAG, Saacke, Vollmer, Rollomatic, Schütte, Strausak, Schneeberger, Reinecker, and others.

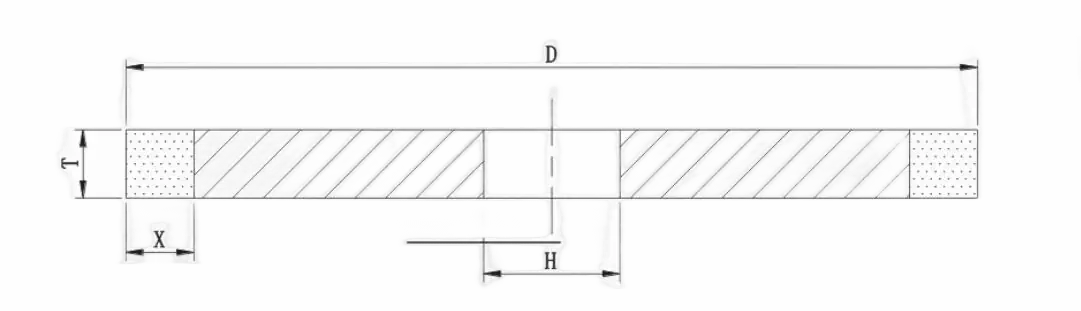

Standard 1A1 configurations include the following common sizes and associated specifications:

- Diameter (D) 75mm (3″):

- Thickness (T) range: 1-12mm (approx. 1/25″ – 1/2″)

- Rim Width (X): 10mm (approx. 2/5″)

- Available Grits: Diamond D64, D54, D46, D35; CBN B126, B91, B76, B54.

- Diameter (D) 100mm (4″):

- Thickness (T) range: 1-16mm (approx. 1/25″ – 2/3″)

- Rim Width (X): 10mm (approx. 2/5″)

- Available Grits: Diamond D64, D54, D46, D35; CBN B126, B91, B76, B54.

- Diameter (D) 125mm (5″):

- Thickness (T) range: 1-16mm (approx. 1/25″ – 2/3″)

- Rim Width (X): 10mm (approx. 2/5″)

- Available Grits: Diamond D64, D54, D46, D35; CBN B126, B91, B76, B54.

- Diameter (D) 150mm (6″):

- Thickness (T) range: 2-16mm (approx. 1/12″ – 2/3″)

- Rim Width (X): 10mm (approx. 2/5″)

- Available Grits: Diamond D64, D54, D46, D35; CBN B126, B91, B76, B54.

(Note: Grit codes D64 down to D35 and B126 down to B54 represent a range from medium-fine to fine finishes, suitable for precision slotting.)

The critical Hole Size (H / Bore Diameter) is manufactured to order, tailored precisely to your machine’s arbor or flange specifications (common standards like 20mm or 31.75mm / 1.25 inches and others are available upon request).

As high-performance slotting often requires tailored solutions, ZYsuperhard offers full customization based on your specific drawings or detailed requirements. This includes non-standard dimensions (D, T, H, X), specific grit sizes within the Diamond/CBN range, concentrations, or minor bond modifications.

Contact our CNC grinding application specialists to discuss your slotting requirements and determine the optimal hybrid bond wheel specification for your machine and workpiece.