-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

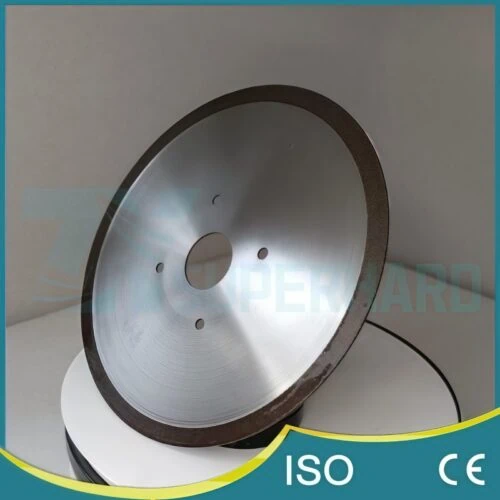

14U1 CBN Grinding Wheels

Upgrade low-speed grinders with 14U1 resin bond CBN wheels. Excel in precision grinding of steels & cast iron, providing superior durability and accuracy vs conventional wheels. Custom designs.

14U1 Resin Bond CBN Grinding Wheels for Low-Speed Grinders

Significantly enhance the precision grinding capabilities and extend tool life on your conventional low-speed grinding machines with these specialized 14U1 Resin Bond CBN Wheels from ZYsuperhard. Designed as a high-performance upgrade alternative to ordinary abrasive wheels (like aluminum oxide or silicon carbide), they deliver exceptional accuracy, superior surface finish, and outstanding durability when processing hardened steels, high-speed steels (HSS), cast irons, and challenging alloys.

Upgrading Low-Speed Grinding with Resin Bond CBN Technology

While Cubic Boron Nitride (CBN) is known for high-speed grinding, utilizing these advanced resin bond CBN wheels on lower-speed equipment offers distinct advantages over traditional abrasives:

- Dramatically Increased Wheel Life: CBN’s extreme hardness translates to vastly superior wear resistance compared to conventional grits, meaning significantly longer grinding time between wheel changes or dressing cycles, boosting overall productivity.

- Superior Form Holding & Dimensional Accuracy: The wheel maintains its precise profile (like the 14U1 shape) much longer, ensuring consistent part geometry and tight dimensional tolerances throughout the production run.

- Improved Surface Integrity & Reduced Burn Risk: CBN cuts cleanly and the resin bond facilitates cooler grinding compared to conventional abrasives at lower surface speeds. This minimizes the risk of thermal damage, micro-cracks, or undesirable metallurgical alterations on the workpiece surface.

- Enhanced Overall Efficiency: Although operating at lower speeds, the combination of longer wheel life, reduced dressing frequency, and consistent cutting action often results in higher overall process efficiency and lower cost-per-part.

The 14U1 Profile for Specific Grinding Tasks

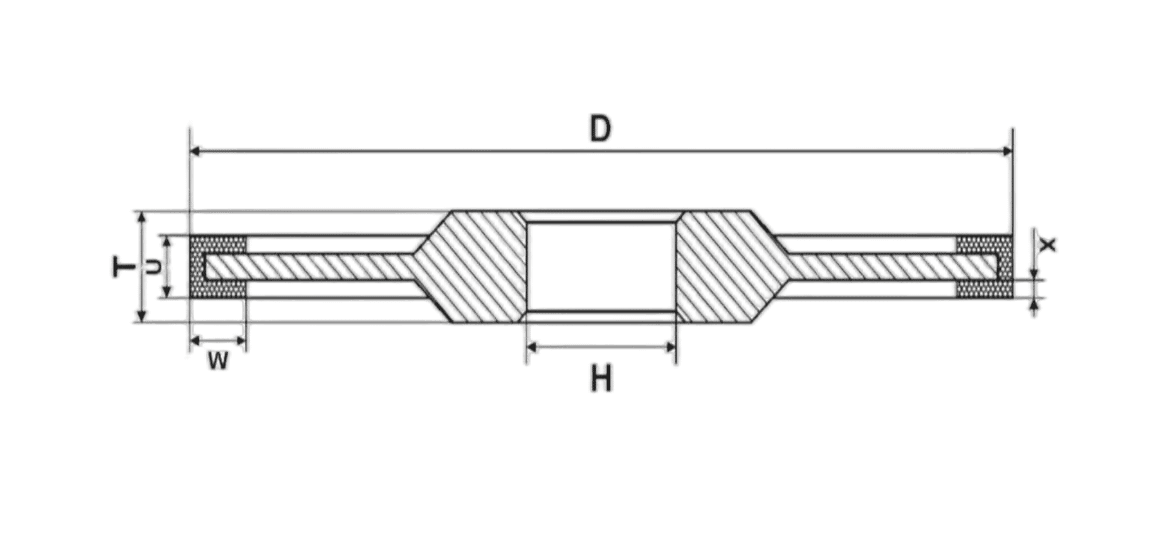

The 14U1 designation typically indicates a specific wheel profile (geometry potentially defined by parameters like T, U, W, X – confirmation via drawing needed), often suited for precision grinding tasks in key industries:

- Application Areas: Widely used for precision grinding of critical iron-based components in sectors such as Automotive (engine parts, transmission components), Bearing manufacturing, Compressor parts, and Precision Die & Mold making. Specific tasks depend on the exact 14U1 geometry detailed in the customer drawing.

Key Performance Advantages

- Long Life Replacement for Conventional Wheels on Low-Speed Grinders.

- High Precision and Consistent Geometric Accuracy.

- Superior Surface Finish with Reduced Risk of Thermal Damage.

- Effective on a Wide Range of Hard Ferrous Materials: HSS, Hardened Steels (>HRC 50), Die Steels, Alloy Steels, Aerospace Alloys, Cast Iron, Stainless Steels (including nitrided).

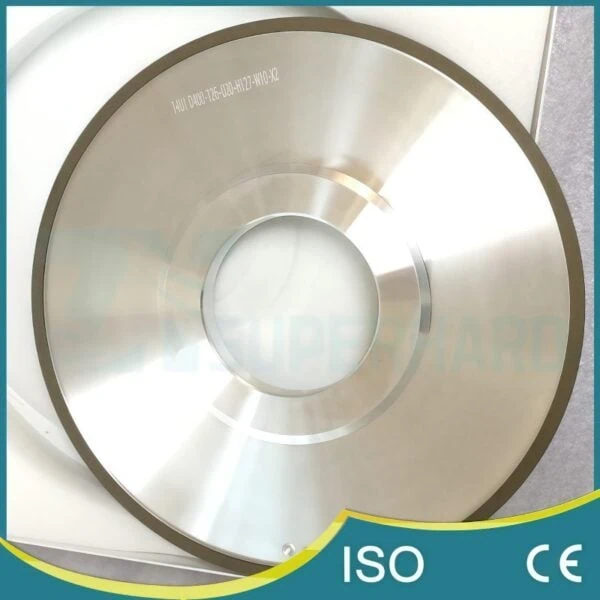

Customized Specifications for Your Application

These specialized 14U1 wheels are manufactured based on detailed customer requirements to ensure optimal performance:

- Drawing-Based Production: We typically require your engineering drawing specifying the exact 14U1 profile and all critical geometric dimensions.

- Full Parameter Customization: We tailor the wheel based on key parameters including:

- Core Dimensions: Diameter (D), Hole (H), Total Thickness (T).

- Profile Geometry: Specific dimensions defining the 14U1 shape (often designated U, W, X on drawings, defining recesses or rim features).

- Abrasive: CBN.

- Grit Size: Select from a wide range (e.g., B181 rough to B46 fine, or finer) based on your required finish and removal rate.

- Concentration: Specify CBN concentration (e.g., 100%, 125% are common options).

- Bond Formulation: Potential adjustments to resin bond characteristics for specific materials or conditions (dry/wet).

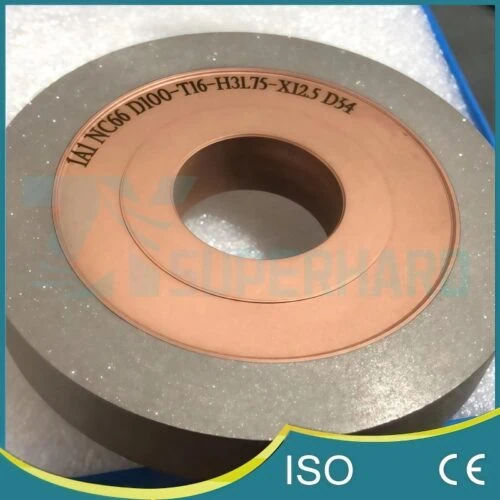

- Example of a Full Specification: To illustrate the necessary detail, for instance, one specific configuration produced for Hardened Steel grinding is: 14U1 Resin CBN D400*H127*T26*U20*W10*X2 (with appropriate CBN grit and concentration, e.g., B170 at 100%). Remember, all parameters are fully customizable per your drawing.

ZYsuperhard ensures each custom wheel meets your precise geometric and performance criteria for upgrading your low-speed grinding operations.

Contact our grinding application engineers with your workpiece material, machine type, desired outcome, and wheel drawing or specifications for a custom 14U1 resin bond CBN wheel solution.