-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

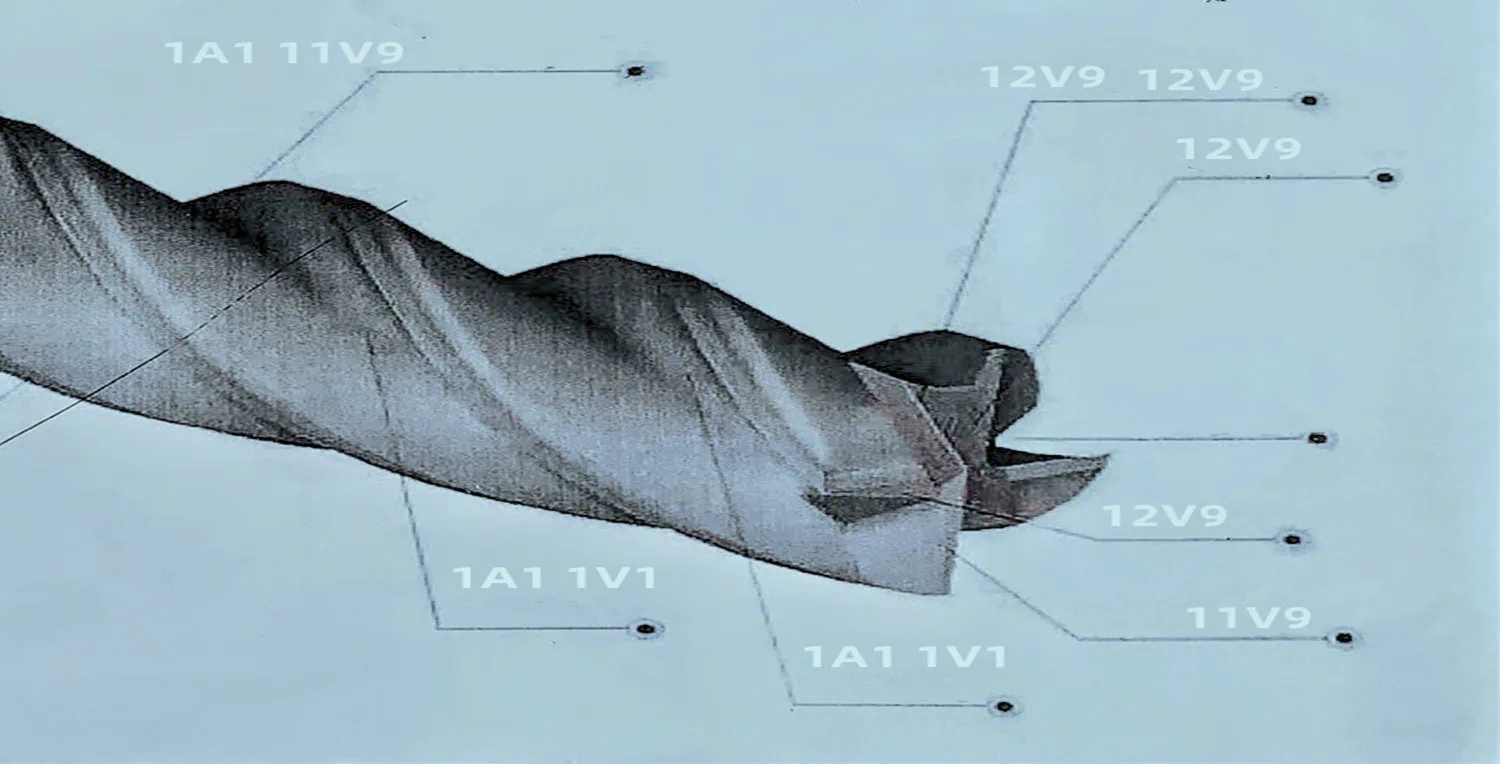

11V9 12V9 Hybrid Bond Diamond And Cbn Grinding Wheels

Precision 11V9 & 12V9 hybrid bond wheels for CNC grinding carbide/HSS tools. Diamond/CBN options provide superior performance & retention for relief angles (11V9) and flute/gash work (12V9).

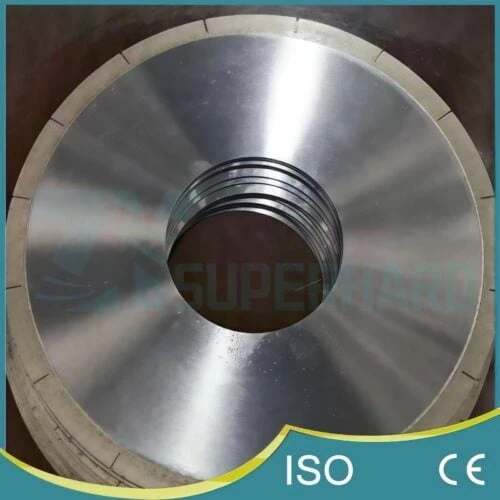

High-Performance 11V9 & 12V9 Hybrid Bond Wheels for CNC Tool Grinding

Elevate your CNC tool grinding operations with ZYsuperhard’s advanced 11V9 and 12V9 Hybrid Bond Grinding Wheels. Engineered specifically for the precision batch production and regrinding of Tungsten Carbide (Hard Alloy) and High-Speed Steel (HSS) cutting tools, these wheels offer a superior combination of aggressive grinding performance, exceptional form holding (retention), and significantly extended wheel life, making them the ideal choice for demanding, high-efficiency tool manufacturing and sharpening environments utilizing multi-axis CNC grinders.

The Hybrid Bond Advantage for Batch Processing:

Our innovative hybrid bond technology represents a leap forward, blending the benefits of multiple binder systems (resin, metal, others) to deliver performance characteristics crucial for automated or semi-automated CNC tool grinding workflows:

- Optimized Performance Balance: Achieves both high material removal rates necessary for efficient cycle times and the capability to produce excellent surface finishes and sharp, durable cutting edges.

- Superior Form Retention: Exhibits markedly better profile retention compared to conventional resin bonds, maintaining critical geometric accuracy over extended grinding periods. This is vital for batch processing where tool-to-tool consistency is paramount with minimal need for in-process wheel dressing or operator compensation.

- Enhanced Process Stability: Offers reliable, predictable, and consistent grinding behavior, making it well-suited for the complex multi-axis grinding paths common in modern CNC tool and cutter grinder programming (e.g., flute grinding, gashing, clearance angles).

Specialized Shapes for Key Tool Grinding Operations:

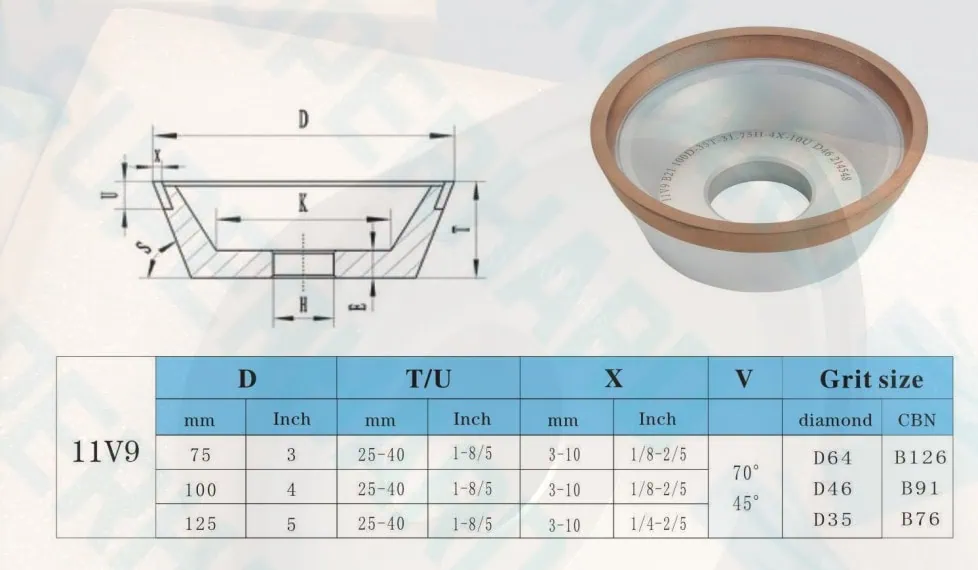

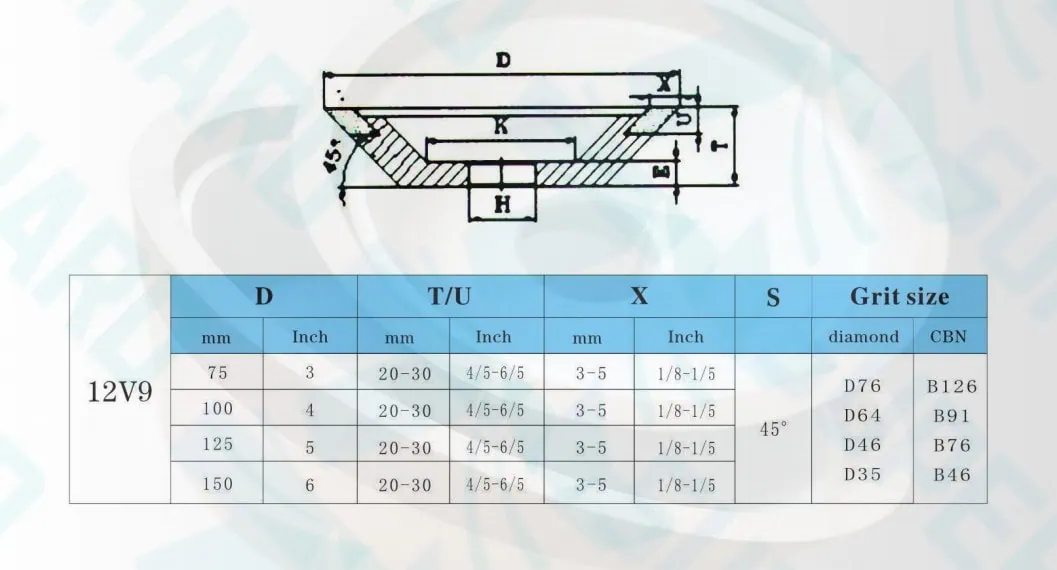

We offer these two industry-standard cup wheel shapes, each optimized for specific, critical tool grinding tasks as often illustrated in tool grinding diagrams (like the sample image):

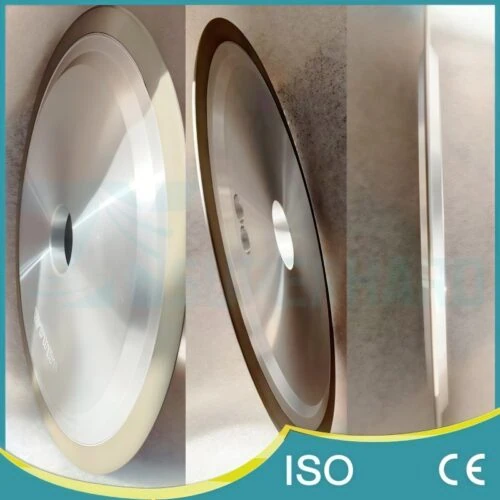

- 11V9 Shape Grinding Wheel: Characterized by its flared cup shape providing a substantial grinding face/rim. The 11V9 wheel is primarily utilized for accurately grinding peripheral relief angles (primary and secondary), axial primary relief angles, and profile relief angles on milling cutters, reamers, and other cutting tools.

- 12V9 Shape Grinding Wheel: Typically designed with a thinner profile rim or a specific edge angle. The 12V9 wheel excels in efficiently grinding intricate features such as chip pockets (flutes), end gashes, axial rake angles, and chip breakers on tools like end mills and drills, where access and profile accuracy are key.

Abrasive Options Tailored to Your Tool Material:

Select the appropriate superabrasive grain for maximum performance on your specific tool material:

- Diamond (D): The optimal choice for grinding Tungsten Carbide (Hard Alloy) tools. Available in various micron grit sizes (e.g., D35, D46, D64, D76) for different finishing requirements.

- CBN (B – Cubic Boron Nitride): The preferred abrasive for grinding High-Speed Steel (HSS), hardened tool steels, die steels, and other ferrous materials. Available in various micron grit sizes (e.g., B46, B76, B91, B126). (Selecting the correct fine micron grit ensures excellent cutting edge quality and surface finish on the tool.)

Core Applications & Industries:

These high-performance hybrid bond wheels are indispensable tools for:

- Cutting Tool Manufacturers: Efficiently producing high-quality Tungsten Carbide and HSS end mills, drills, reamers, taps, profile cutters, and other precision cutting tools in demanding batch production environments.

- Tool Regrinding & Sharpening Services: Cost-effectively restoring cutting edges and precise geometries on worn carbide and HSS tools to meet original or custom specifications, serving a wide range of industries.

- In-House Tool Rooms: Supporting critical manufacturing operations within large Aerospace, Automotive, and Mold & Die companies by efficiently maintaining and reconditioning essential cutting tools, ensuring production continuity and quality.

Specification Tables:

Sample Application Illustration:

Customization:

Beyond potentially standard listed specifications, ZYsuperhard offers fully customized 11V9 and 12V9 hybrid bond wheels. We can tailor dimensions (Diameter, Thickness, Hole Size, Rim dimensions W/X/Angle), abrasive type (Diamond/CBN), specific grit size, concentration level, and bond formulation characteristics to precisely match your CNC grinding machine, coolant system, target tool geometry, and specific performance requirements.

Benefits Summary:

- Achieve high geometric accuracy on complex cutting tool features (angles, radii, profiles).

- Produce superior cutting edge quality (sharpness, low chipping) and surface finish.

- Optimize grinding cycle times with balanced, efficient performance.

- Benefit from extended wheel life and excellent form retention, crucial for batch production consistency.

- Ensure reliable and predictable performance on multi-axis CNC tool grinders.

Choose ZYsuperhard 11V9 and 12V9 hybrid bond wheels for consistent, high-quality results and improved productivity in your precision tool manufacturing and regrinding operations. Contact us to discuss your requirements.