-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

All You Need To Know About Polycrystalline Diamond (PCD) Tools

- Knowledge, PCD & CBN Tools Knowledge

- -2025-04-04

- - byKevin Ray

What exactly are Polycrystalline Diamond (PCD) tools, and how do you know when they are the right choice for your machining needs?

Polycrystalline Diamond (PCD) tools1 are advanced cutting tools made from a synthetic composite material created by sintering diamond particles with a metallic binder under extreme conditions. Furthermore, they should be used primarily for machining highly abrasive non-ferrous metals, composites, wood products, and certain ceramics, especially in high-volume applications where their exceptional wear resistance and long tool life lead to significant long-term cost savings despite a higher initial price.

Table of Contents

ToggleWhat Exactly Is Polycrystalline Diamond and How Is It Created?

Ever wondered what makes Polycrystalline Diamond, or PCD, such a special material for cutting tools and how it’s actually made?

Polycrystalline Diamond (PCD) is a man-made composite material created by fusing together tiny, synthetic diamond particles with a metallic binder under extreme heat and pressure. Furthermore, this process, called sintering, results in an incredibly hard and wear-resistant material specifically engineered for demanding cutting tool applications.

Let’s break down how this impressive material comes to life and what makes it unique.

The High-Pressure, High-Temperature (HPHT) Sintering Process

Think of making PCD like baking a very special, very strong cake. Instead of flour and sugar, scientists use tiny, man-made diamond crystals, often microns in size (that’s incredibly small!), mixed with a metal powder, usually cobalt. Then, this mixture goes into a special press.

This isn’t just any press; it applies High Pressure and High Temperature (HPHT) simultaneously. How high?

- Pressure: Often reaching 5.5 Gigapascals (GPa) or more. To put that in perspective, that’s like stacking dozens of cars onto an area the size of your thumbnail! It mimics the intense pressures found deep within the Earth where natural diamonds form.

- Temperature: Typically around 1450 degrees Celsius (or 2640 degrees Fahrenheit). That’s significantly hotter than volcanic lava.

Important Note: These pressure and temperature parameters can vary depending on the specific PCD grade being produced and the manufacturer’s proprietary process.

So, why use such extreme conditions? This intense heat and pressure force the individual diamond particles to bond directly to each other, a process called sintering2. Additionally, the metallic binder melts and flows into the spaces between the diamond grains, acting like a super-strong glue or matrix. Subsequently, this creates a solid, dense mass – a PCD blank or disc – where the diamond crystals are locked together.

Understanding the Diamond-Binder Composite Structure

Diamond Grains

These synthetic diamond particles provide the primary cutting edges and are responsible for PCD’s incredible hardness and resistance to wear. Think of them as the tough, sharp teeth of the material at a microscopic level.

Metallic Binder

Typically cobalt, this metal fills the gaps between the diamond grains. It serves several crucial functions:

- It holds the diamond grains together securely.

- It adds crucial toughness (resistance to chipping or breaking), making PCD less brittle than a large, single diamond crystal.

- It helps conduct heat away from the cutting edge during machining operations.

A key feature of the PCD structure is that the diamond crystals are randomly oriented. Unlike a natural diamond which has specific cleavage planes (directions it can split easily), the random arrangement in PCD means it has uniform hardness and wear resistance in all directions. This makes it much more reliable and predictable as a cutting tool material.

The resulting PCD material isn’t pure diamond. Instead, it’s a composite material, meaning it’s made from two main components working together:

Often, this layer of PCD material (which might be only 0.5mm thick, for example) is then bonded, usually through brazing or another sintering step, onto a much thicker tungsten carbide substrate. Why? Because tungsten carbide is very tough and provides strong, rigid support for the relatively thin PCD layer. This substrate also makes it easier to fabricate the final cutting tool insert and clamp it securely in a tool holder.

Key Differences: PCD vs. CBN, Natural Diamond & Carbide

Understanding PCD often involves comparing it to other significant hard materials used in tooling: its superhard counterpart Cubic Boron Nitride (CBN), the ultimate benchmark Natural Diamond, and the widely used Tungsten Carbide. So, how do they stack up?

| Feature | Polycrystalline Diamond (PCD) | Cubic Boron Nitride (CBN) | Natural Diamond (Single Crystal) | Tungsten Carbide (WC) |

|---|---|---|---|---|

| Source | Man-made / Synthetic | Man-made / Synthetic | Natural | Man-made / Synthetic |

| Structure | Composite (Diamond Grains + Metal Binder) | Composite (CBN Grains + Binder, often Ceramic or Metal) | Single Crystal | Composite (WC Grains + Cobalt Binder) |

| Hardness | Very High (Lower than natural diamond) | Very High (Second to diamond) | Highest Known | High (Lower than CBN/PCD) |

| Toughness | Moderate (Lower than CBN/Carbide) | Moderate to High (Higher than PCD) | Low (Brittle) | High (Higher than PCD/CBN) |

| Wear Resistance | Excellent (Uniform, esp. abrasive non-ferrous) | Excellent (Esp. hard ferrous at high temps) | Extremely High (Directional) | Good to Very Good |

| Thermal Conductivity | High | High (Lower than PCD) | Very High | Moderate |

| Chemical Stability (vs. Iron) | Poor at high temp | Excellent | Poor at high temp | Good |

| Primary Tool Use | Non-ferrous metals, composites, wood, plastics | Hardened steels (>45 HRC), cast irons, superalloys, sintered metals | Ultra-precision finishing, specialized | Ferrous metals (general), non-ferrous, high impact |

In essence, PCD captures much of diamond’s hardness and wear resistance but with improved toughness and uniform properties. Natural diamond, while hardest, is brittle and directional, reserved for niche applications. Tungsten Carbide is the tough workhorse, excellent for steels and general use but lacks the wear resistance of PCD/CBN in highly abrasive or hard materials. Crucially, Cubic Boron Nitride (CBN) complements PCD; while PCD excels on non-ferrous and abrasive non-metals, CBN offers the chemical stability and high-temperature hardness needed to effectively machine hard ferrous materials like hardened steels and cast irons, where PCD typically fails due to chemical reaction. Therefore, PCD and CBN together cover a vast range of demanding machining applications. You can explore more about the specific differences between PCD and Carbide Tools3, and understanding the PCD vs. CBN distinction4 is key for selecting the right superhard material.

Why Do PCD Tools Offer Superior Performance?

So, what actually makes Polycrystalline Diamond (PCD) tools perform so much better than traditional cutting tools in certain situations?

PCD tools offer superior performance primarily due to their exceptional hardness and wear resistance, which leads to dramatically longer tool life compared to carbide or HSS. Furthermore, their high thermal conductivity helps manage heat during cutting, contributing to better precision and surface finishes on workpiece materials.

Let’s explore these performance advantages in more detail.

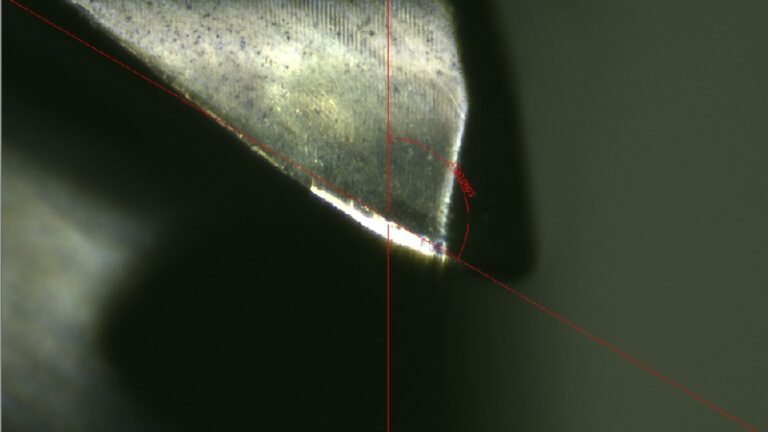

Extreme Hardness and Wear Resistance Explained

As we learned earlier, diamond is the hardest naturally occurring material known. PCD harnesses this property by using tiny synthetic diamond crystals locked together. This translates directly into two critical performance benefits: extreme hardness and exceptional wear resistance.

- Hardness: Think of hardness as a material’s ability to resist scratching or denting. Because PCD is composed mainly of diamond particles, it ranks very high on the hardness scale, significantly harder than conventional materials like tungsten carbide or high-speed steel (HSS).

- Wear Resistance: This is where PCD truly shines, especially against abrasive wear. Wear resistance is the tool’s ability to withstand gradual damage and erosion during the cutting process. Imagine trying to cut coarse sandpaper with a standard steel knife – the knife edge would dull almost instantly. Now, imagine a material that can cut that sandpaper for a very long time without getting dull. That’s similar to how PCD behaves when machining abrasive materials. Understanding the common tool wear mechanisms is key to appreciating PCD’s advantage.

Materials like high-silicon aluminum alloys (common in automotive parts), metal matrix composites (MMCs), fiberglass, carbon fiber reinforced plastics (CFRP), and wood composites (like MDF or particleboard containing abrasive fillers and binders) are notoriously tough on cutting tools. The hard particles or fibers within these materials act like tiny grinding agents, rapidly wearing down conventional tool edges. PCD’s diamond structure, however, effectively resists this abrasive action, maintaining its cutting edge integrity for much longer. The interlocked diamond crystals provide a continuous, ultra-hard surface that simply doesn’t get worn away easily.

Quantifying the Tool Life Advantage Over Carbide/HSS

One of the most compelling reasons manufacturers switch to PCD is the dramatic increase in tool life. How much longer can PCD tools last?

While it varies greatly depending on the specific job, it’s common for PCD tools to last 10 to 100 times longer, sometimes even more, than comparable tungsten carbide tools in the right applications. The difference compared to High-Speed Steel (HSS) tools is even greater, often measured in hundreds of times.

Consider these industry examples:

- Automotive: When machining aluminum engine blocks or pistons containing high silicon content (e.g., A390 alloy), a carbide insert might need replacement after machining several hundred components. In contrast, a PCD insert performing the same operation could potentially machine tens of thousands of components before needing replacement.

- Woodworking/Furniture: In high-volume panel processing (like cutting or edge-profiling MDF or particleboard), carbide router bits or saw blades might require sharpening daily or weekly. A PCD equivalent, however, could operate continuously for months, or in some cases, even over a year, before requiring service.

This massive increase in tool life leads directly to significant benefits for PCD diamond inserts:

- Reduced Machine Downtime: Less time spent stopping machines to change worn tools.

- Consistent Quality: Parts maintain consistent dimensions and finish over longer production runs.

- Lower Tooling Cost Per Part: Although the initial cost of a PCD tool is higher, its extended life often results in a lower overall cost for each part produced.

Important Note: It’s crucial to remember that these tool life figures are indicative ranges. Actual results depend heavily on factors like the exact material being cut, the cutting speed and feed rates used, the rigidity and condition of the machine tool, the use of coolant, and the specific grades of PCD and carbide tools being compared. Therefore, consulting with tooling suppliers is essential to get realistic tool life projections for your specific machining scenario.

The Impact of High Thermal Conductivity in Machining

Cutting metal, wood, or composites generates a lot of heat right at the point where the tool meets the material. This heat comes from friction and the energy used to deform and shear the material being cut. Effectively managing this heat is critical for tool life and part quality.

This is another area where PCD excels due to its high thermal conductivity. Diamond is one of the best thermal conductors known – it transfers heat incredibly well, even better than copper!

How does this help in machining?

- Cooler Cutting Edge: PCD quickly draws heat away from the sharp cutting edge and conducts it into the body of the tool insert and the carbide substrate. Keeping the edge cooler helps it maintain its hardness and dramatically slows down wear mechanisms that accelerate at high temperatures (like diffusion wear).

- Reduced Workpiece Damage: By preventing excessive heat buildup at the cutting zone, PCD minimizes the risk of thermal damage to the workpiece, such as warping, burning, or undesirable changes in the material’s structure near the cut surface.

- Potential for Higher Speeds: Because heat is managed more efficiently, it’s often possible to run PCD tools at significantly higher cutting speeds compared to carbide, boosting productivity without sacrificing tool life proportionally.

- Less Material Adhesion: Particularly when machining non-ferrous metals like aluminum, high heat can cause the workpiece material to soften and stick to the tool tip, forming what’s called a “built-up edge” (BUE). PCD’s ability to stay cooler, combined with its low chemical reactivity with materials like aluminum, greatly reduces the tendency for BUE to form.

Achieving Enhanced Precision and Surface Finishes

The combination of extreme wear resistance, thermal stability, and other properties allows PCD tools to produce parts with higher precision and superior surface finishes. Here’s why:

- Edge Retention: A tool that stays sharp cuts cleanly. Because PCD resists wear so effectively, it maintains a keen cutting edge for a very long time. A sharp edge shears the material cleanly with less force, minimizing tearing or smearing and leaving a smoother surface. This also helps maintain accurate part dimensions consistently over long runs.

- Lower Friction: As mentioned previously, PCD often exhibits lower friction against certain workpiece materials compared to carbide. Lower friction translates to lower cutting forces, less deformation of the material being cut, and a reduced likelihood of built-up edge formation – all factors contributing to a better finish.

- Thermal and Mechanical Stability: PCD’s high thermal conductivity prevents excessive heat buildup, while the inherent stiffness (high modulus of elasticity) and low thermal expansion of diamond mean the tool tip doesn’t deform or change size significantly under cutting loads and temperatures. This stability is crucial for holding tight dimensional tolerances.

Consequently, PCD tooling is often the preferred choice when machining components requiring very fine surface finishes (sometimes approaching mirror-like quality on aluminum or copper) and close dimensional accuracy, such as in aerospace components, automotive powertrain parts, or precision molds.

Which Materials and Applications Are Ideal for PCD Tools?

Knowing how great PCD tools can be, where exactly are they the best choice to use?

PCD tools are ideal for machining highly abrasive non-ferrous metals (like high-silicon aluminum), composites (such as carbon fiber and fiberglass), wood products (especially MDF and particleboard), and certain plastics and ceramics. Consequently, they are widely used in industries like automotive, aerospace, woodworking, and electronics manufacturing.

Let’s dive into the specific materials, industries, and operations where PCD truly excels.

Best-Fit Materials: Non-Ferrous Metals, Composites, Wood Products, and More

The key reason PCD tools outperform others is their incredible resistance to abrasive wear. Therefore, they are most effective when working with materials that would quickly dull or destroy conventional cutting tools like high-speed steel (HSS) or even standard tungsten carbide.

Here’s a breakdown of materials perfectly suited for PCD tooling:

Non-Ferrous Metals

- High-Silicon Aluminum Alloys: These are very common in automotive parts (like engine blocks, cylinder heads, pistons, transmission casings, and wheels). The silicon content, while improving the aluminum’s properties, makes it extremely abrasive. PCD handles this abrasion exceptionally well.

- Copper and Copper Alloys (Brass, Bronze): Often used for electrical components and plumbing fixtures, these materials machine well with PCD, allowing for excellent surface finishes.

- Magnesium Alloys: Used where light weight is critical, these also machine effectively with PCD.

- Important Limitation: It’s crucial to note that PCD is generally not suitable for machining ferrous metals like steel, stainless steel, or cast iron. At the high temperatures generated during cutting, a chemical reaction can occur between the carbon in the diamond tool and the iron in the workpiece, leading to rapid chemical wear (diffusion) and tool failure. For these challenging ferrous applications, especially hardened steels (typically above 45 HRC), cast irons, and superalloys, Cubic Boron Nitride (CBN) tools are the preferred superhard material choice due to their excellent thermal and chemical stability when machining iron-based materials.

Composite Materials

- Carbon Fiber Reinforced Plastics (CFRP): Extensively used in aerospace, high-performance automotive, and sporting goods for their high strength-to-weight ratio. The carbon fibers are extremely hard and abrasive, making PCD the go-to choice for trimming, drilling, and milling these materials without excessive tool wear or delamination.

- Glass Fiber Reinforced Plastics (GFRP or Fiberglass): Common in boat hulls, automotive panels, wind turbine blades, and construction. Like CFRP, the glass fibers are very abrasive, necessitating PCD for efficient machining.

- Metal Matrix Composites (MMCs): These combine a metal (often aluminum) with reinforcing particles (like silicon carbide or alumina). The reinforcing particles make MMCs incredibly abrasive, often requiring PCD tooling for effective cutting.

Wood and Wood Products

- Engineered Woods: PCD excels in cutting Medium-Density Fiberboard (MDF), High-Density Fiberboard (HDF), and Particleboard (Chipboard). These materials contain abrasive resins and wood fibers that rapidly wear down carbide tools in high-volume production.

- Laminates: High-Pressure Laminates (HPL) used for countertops and decorative surfaces, as well as laminated flooring, are effectively cut and shaped using PCD.

- Hard Natural Woods: While carbide works for many woods, particularly abrasive or dense hardwoods can also benefit from the extended life of PCD tooling.

Other Materials

- Green Ceramics: Machining ceramic parts before final firing (when they are in a softer, ‘green’ state) can sometimes be done with PCD.

- Hard/Filled Plastics: Some plastics containing abrasive fillers (like glass fibers) machine better with PCD.

- Concrete: Specialized PCD segments are designed specifically for grinding concrete floors and removing tough coatings like epoxy or mastic – a distinct but important application.

Common Industries Benefiting from PCD Technology

Given the materials PCD handles well, several key industries rely heavily on this technology:

- Automotive: This is a major user of PCD for high-volume machining of abrasive aluminum alloys used in engines (blocks, heads, pistons), transmissions, wheels, and other components. Consistency and long tool life are critical here.

- Aerospace: Essential for machining lightweight aluminum airframe structures and, perhaps more importantly, for drilling, routing, and trimming abrasive composite materials (CFRP) used extensively in modern aircraft bodies and wings. Precision and avoiding damage to expensive composite parts are paramount.

- Woodworking & Furniture: Widely used in factories producing furniture, cabinetry, and flooring from MDF, particleboard, and laminated panels. PCD allows for long, uninterrupted production runs when cutting, routing, or edge-banding these abrasive materials.

- Electronics: Used for machining non-conductive composite materials for circuit boards (like FR-4) and potentially some ceramic or plastic components used in electronic devices.

- Construction & Flooring: Utilizes specialized PCD tools for surface preparation, specifically grinding concrete floors and removing old coatings before new flooring is installed.

- Energy: Applications include machining fiberglass components for wind turbine blades and potentially some non-ferrous or composite parts used in other energy sectors.

Typical Machining Operations: Milling, Turning, Drilling, Grinding, Sawing

PCD’s versatility means it can be fabricated into various tool shapes to perform numerous machining operations, particularly on the suitable materials mentioned above:

- Milling: Using PCD-tipped inserts in face mills (for flattening large surfaces like engine blocks), solid PCD end mills (for pocketing or profiling), or PCD router bits (common in woodworking and composites).

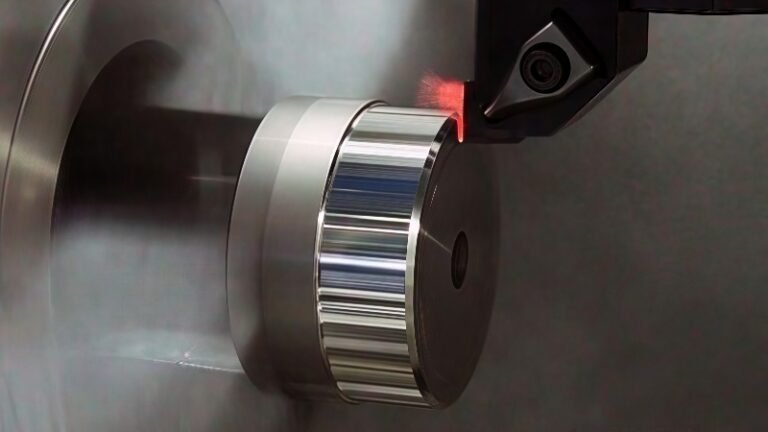

- Turning: Employing PCD inserts on lathes to machine the outer or inner diameters of parts like aluminum pistons, brake discs (non-ferrous types), or copper commutators, often achieving excellent surface finishes.

- Drilling: Utilizing drills with PCD tips or veins for creating holes in abrasive materials like CFRP stacks in aerospace (preventing fiber pull-out) or high-silicon aluminum castings.

- Reaming & Boring: Using PCD tools to achieve highly accurate final dimensions and smooth finishes in holes drilled in suitable materials.

- Sawing: Employing large circular saw blades tipped with PCD segments for cutting stacks of laminated flooring, large panels of particleboard/MDF, or non-ferrous extrusions.

- Grinding: This term needs clarification. While PCD tools themselves require specialized grinding processes (like EDM or laser, discussed later) to be manufactured, specialized PCD segments are the primary cutting element used for grinding concrete floors. For other materials, PCD cutting often eliminates the need for a separate grinding step by producing a superior finish directly.

- Other Operations: PCD tools are also designed for specific tasks like grooving, chamfering, and complex profiling operations.

How Are Specific PCD Tools Manufactured and Classified?

Since PCD material is so incredibly hard, how do manufacturers actually shape it into the specific cutting tools we use, and how is PCD classified?

Shaping ultra-hard PCD blanks into precise tool geometries requires advanced techniques like specialized diamond wheel grinding, Electrical Discharge Machining (EDM), and laser cutting. Furthermore, PCD materials are classified into different grades, primarily based on diamond grain size, which affects the tool’s wear resistance and toughness.

Let’s explore the sophisticated methods used to create these tools and understand how different types of PCD are categorized.

Techniques for Shaping PCD Blanks: Grinding, EDM, Laser

Once the basic PCD material is created through the HPHT process (producing a blank disc, often already bonded to a carbide substrate), it needs to be precisely shaped into a cutting tool edge. Because PCD is nearly as hard as diamond itself, traditional cutting or machining methods won’t work. Instead, specialized techniques are required:

Specialized Diamond Grinding

You can’t effectively grind diamond with anything less hard than diamond itself. Therefore, shaping PCD often involves grinding wheels made with fine synthetic diamond particles embedded in a metal or resin bond. This process is slower than grinding conventional metals and requires very rigid, precise grinding machines. It’s typically used for creating flat surfaces, simple angles, or sharpening the final cutting edge.

Electrical Discharge Machining (EDM)

This clever technique uses controlled electrical sparks to erode material, working well for complex shapes. It takes advantage of the electrical conductivity provided by the metallic binder within the PCD composite.

- Wire EDM: A thin, continuously moving wire acts as one electrode, and the PCD blank is the other. Sparks jump between the wire and the PCD, precisely eroding the material along a programmed path. This is commonly used to cut PCD insert shapes from larger discs.

- Sinker EDM (Die-Sinking EDM): Uses a custom-shaped electrode (often graphite or copper) that is plunged into the PCD blank. Sparks erode the PCD material, essentially creating a cavity that matches the electrode’s shape. This can be used for creating features like chipbreaker geometries.

Laser Cutting / Ablation

A highly focused, high-power laser beam is used to melt or vaporize the PCD material very precisely. This method is excellent for cutting intricate shapes, creating sharp edges, or etching features like chipbreakers or markings onto the tool surface. It can often be faster than EDM for cutting profiles from PCD blanks.

After the PCD segment is accurately shaped using one or more of these methods, it’s typically attached to a tool body (usually tungsten carbide for inserts, drills, end mills, etc., or steel for saw blades) using a high-strength brazing process. This involves carefully heating the parts and melting a specialized filler alloy in the joint to create a strong, durable bond capable of withstanding cutting forces.

Understanding Different PCD Grades and Grain Sizes

Not all PCD is created equal. Manufacturers offer different grades of PCD, much like different recipes, each designed with slightly different properties to suit specific applications. The most significant factor determining a PCD grade’s characteristics is the average diamond grain size used in its manufacture, measured in micrometers (µm).

Here’s how grain size generally affects performance:

| Grain Size Category | Typical Size Range (µm)* | Key Characteristics | Primary Uses |

|---|---|---|---|

| Fine / Ultra-Fine | ~ 2 – 5 µm | Best surface finish, sharpest edge possible; Lower toughness & abrasion resistance | Finishing cuts, materials requiring mirror finishes (some plastics, Al) |

| Medium | ~ 10 – 25 µm | Good balance of wear resistance & toughness; Good edge quality & finish capability | General purpose machining (Al alloys, wood composites, many composites) |

| Coarse / Extra-Coarse | ~ 30 – 50+ µm | Highest toughness & abrasion resistance; Rougher surface finish | Roughing cuts, highly abrasive materials (MMCs, fiberglass), interrupted cuts; Concrete grinding segments |

*Note: These size ranges are general examples. Actual classifications and grade designations vary significantly between PCD manufacturers.

Why the difference?

- Finer grains allow for a sharper, smoother cutting edge initially, leading to better surface finishes. However, having more binder material exposed between the smaller grains can sometimes make them slightly less resistant to heavy abrasion and impact compared to coarser grades.

- Coarser grains create a tougher structure with higher resistance to chipping and better performance in highly abrasive materials or roughing operations where impact resistance is needed. However, the larger grains result in a slightly less sharp edge and typically produce a rougher surface finish.

Other factors influencing PCD grades include the percentage and type of metallic binder used and sometimes special post-treatments, like polishing the tool’s cutting face (rake face) to reduce friction and prevent material buildup.

Very Important: Because grading systems, grain size categories (e.g., what one company calls “medium,” another might classify differently), and specific grade names (e.g., KD100, CMX850, CTH25 – these are just illustrative examples) are not standardized across the industry, you must consult the specific manufacturer’s technical data sheets. These datasheets provide detailed properties and recommended applications for each of their grades, helping you choose the optimal PCD for your task.

Common PCD Tool Formats: Inserts, End Mills, Drills, Saw Blades

The precisely shaped PCD segments are integrated into different standard and custom tool formats5 to suit different machines and operations:

- Indexable Inserts: These are small, replaceable cutting tips, typically consisting of a PCD layer brazed onto a carbide base that fits into standard tool holders (e.g., ISO standard shapes like CNMG, TPG, VBG). They are widely used for turning, milling, boring, and grooving operations. The main advantage is that only the small insert needs replacement when worn, not the entire tool body.

- End Mills: These rotary cutters feature PCD tips or entire cutting edges brazed onto a solid carbide shank. They are used in milling machines for creating slots, pockets, contours, and profiles, especially valuable in abrasive composites and non-ferrous metals. Formats include square end, ball nose, and corner radius types.

- Drills: Carbide drill bodies equipped with PCD tips at the cutting point. Essential for drilling abrasive materials where conventional drills wear out extremely fast, such as drilling thousands of holes in CFRP for aerospace assemblies.

- Saw Blades: Large circular steel discs with multiple PCD tips brazed onto the periphery as cutting teeth. Used in panel saws or specialized machines for cutting large volumes of wood composites (MDF, particleboard, laminate flooring) or non-ferrous metal extrusions.

- Router Bits: Functionally similar to end mills but often specifically designed with geometries suited for high-speed routing machines used in woodworking and composite fabrication.

- Reamers and Boring Bars: Precision tools designed to finish holes to exact sizes and high surface quality, utilizing PCD edges for long life and accuracy in abrasive materials.

- Specialty Tools: PCD is also used in custom-designed tools for specific tasks like grooving tools, form tools, and the robust segments used in concrete floor grinding heads.

Is Investing in PCD Tools Economically Viable for Your Needs?

Given that PCD tools cost more upfront than standard tools, how do you figure out if they actually make financial sense for your specific job?

Investing in PCD tools becomes economically viable when the long-term savings from dramatically increased tool life, reduced machine downtime, and potentially higher productivity outweigh the higher initial purchase price. Furthermore, suitability hinges on factors like the abrasiveness of the material being machined, production volume, and the cost impact of tool changes.

Let’s examine how to evaluate the cost-effectiveness and successfully implement PCD tooling.

Evaluating the Initial Cost vs. Long-Term Savings

It’s true – PCD tools typically have a significantly higher purchase price compared to their tungsten carbide counterparts, sometimes costing 5, 10, or even 20 times as much, or more. So, why would anyone pay that premium? The answer lies in looking beyond the initial price tag and considering the Total Cost of Ownership (TCO)6 or, more simply, the cost per part produced.

Here’s what contributes to long-term savings with PCD:

- Massively Extended Tool Life: As discussed earlier, PCD can last 10x, 50x, even over 100x longer than carbide in the right application. This means far fewer tools are purchased over time.

- Reduced Machine Downtime: Every time a machine stops to change a worn tool, production halts. This downtime has a cost associated with it (machine hour rate, lost production). Since PCD tools are changed much less frequently, this downtime cost is drastically reduced.

- Lower Tool Change Labor: Fewer tool changes also mean less labor spent on swapping out tools.

- Consistent Quality & Reduced Scrap: PCD tools maintain their edge and size for longer, leading to more consistent part quality and potentially reducing scrap rates caused by worn tooling.

- Potential for Increased Productivity: Often, PCD tools can be run at higher speeds and feeds than carbide, shortening cycle times and increasing throughput.

- Resharpening Potential: Many PCD tools can be resharpened or relapped multiple times by specialized services, further extending their usable life and value (though resharpening also has a cost).

Simplified Cost Per Part Example:

Imagine machining a high-silicon aluminum component:

- Carbide Tool:

- Initial Cost: $20

- Tool Life: 500 parts

- Tool Change Time: 10 minutes

- Machine Downtime Cost during change: $10 (example)

- Calculation:

- Tool cost per part: $20 / 500 parts = $0.040

- Downtime cost per part: $10 / 500 parts = $0.020

- Total Tooling Cost per Part (Carbide): $0.060

- PCD Tool:

- Initial Cost: $200 (10x Carbide)

- Tool Life: 25,000 parts (50x Carbide life)

- Tool Change Time: 10 minutes

- Machine Downtime Cost during change: $10

- Calculation:

- Tool cost per part: $200 / 25,000 parts = $0.008

- Downtime cost per part: $10 / 25,000 parts = $0.0004

- Total Tooling Cost per Part (PCD): ~$0.0084

In this scenario, despite the PCD tool costing 10 times more initially, the tooling cost per part is almost 7 times lower due to its massively extended life and drastically reduced impact of tool change downtime. The payback period – the time it takes for the savings to offset the higher initial cost – can be very short in high-volume or highly abrasive applications.

Important: This is a simplified example. Real-world tool costs, machine rates, labor costs, and achievable tool life vary widely. Consequently, performing a detailed cost analysis tailored to your specific operation, perhaps with input from your tooling supplier, is essential before deciding.

Key Factors for Determining Application Suitability

PCD isn’t the best choice for every situation. It shines brightest under specific conditions. Ask yourself these questions to determine if PCD is likely a good fit:

- What material are you machining? Is it known to be highly abrasive (like high-silicon aluminum, composites, MDF/particleboard)? If yes, PCD is a strong candidate. If it’s steel or stainless steel, PCD is generally unsuitable.

- What is your production volume? Are you making thousands or millions of parts, or running machines continuously? High volume magnifies the savings from long tool life, making PCD very attractive. For prototypes or very short runs, the high initial cost may not be justified.

- How costly is machine downtime? If stopping a machine for even a few minutes significantly impacts your production schedule or costs (e.g., automated lines), the reduction in tool changes offered by PCD is a major benefit.

- How often are you changing tools now? If you’re swapping out carbide tools multiple times per shift due to wear, PCD could offer substantial relief.

- Are tight tolerances or fine surface finishes critical? Can you maintain these consistently with your current tools as they wear? PCD’s ability to hold its edge longer can improve consistency and quality.

- Can your process benefit from higher speeds/feeds? If your machine tools are capable, PCD might allow for faster cycle times, further boosting the economic benefit.

If you answer “yes” to several of these questions, particularly regarding material abrasiveness and production volume/downtime cost, then PCD tooling is likely worth serious consideration.

Tips for Successful Implementation and Use

Switching to PCD isn’t always a simple “plug-and-play” substitution for carbide. To get the maximum benefit and avoid premature tool failure, consider these practical tips:

- Ensure Machine Rigidity: PCD performs best on stable, rigid, well-maintained machine tools. Excessive vibration, spindle runout, or loose workholding can lead to chipping of the relatively brittle PCD edge. Understanding machine tool rigidity is crucial.

- Handle with Care: While extremely hard and wear-resistant, PCD can be chipped if dropped or subjected to sharp impacts. Treat PCD tools with respect during handling and setup.

- Optimize Cutting Parameters: Don’t assume carbide speeds and feeds are appropriate. Work with your tooling supplier to establish optimal parameters (often higher speeds, moderate feeds) for the specific PCD grade and your material. Start conservatively if unsure.

- Use Quality Tool Holders: Employ high-precision, balanced tool holders (like hydraulic chucks, shrink-fit holders, or high-quality collet chucks) with minimal runout to ensure the tool runs true and cutting forces are distributed evenly.

- Manage Coolant Effectively: While PCD tolerates heat well, proper coolant delivery (type, concentration, pressure, and direction) is often still vital for chip evacuation, lubrication (especially in sticky materials like aluminum), and maximizing life. Consult supplier recommendations for wet vs. dry machining.

- Program Smart Entry/Exit Paths: When possible, program tool paths that allow the tool to “roll” into and out of cuts rather than entering or exiting abruptly, especially in interrupted cutting situations. This minimizes impact stress on the cutting edge.

- Train Operators: Make sure machine operators understand the value, handling requirements, and performance characteristics of PCD tooling compared to conventional tools.

- Investigate Resharpening Options: Explore specialized PCD tool resharpening/relapping services. While an added cost, resharpening can significantly extend the tool’s overall value proposition, potentially allowing several ‘lives’ from a single tool. Discuss this possibility with your tool supplier.

By carefully evaluating the economics and implementing PCD tooling thoughtfully, you can unlock significant performance gains and cost savings in demanding machining applications.

Conclusion

Polycrystalline Diamond (PCD) tools represent a significant advancement in cutting tool technology, offering unparalleled performance in specific applications. Created by sintering diamond particles under extreme heat and pressure, PCD combines exceptional hardness and wear resistance with high thermal conductivity. This results in dramatically longer tool life – often 10 to over 100 times that of carbide – especially when machining abrasive non-ferrous metals (like high-silicon aluminum), composites (CFRP, GFRP), and engineered wood products (MDF, particleboard). While PCD excels with these materials, it’s generally unsuitable for ferrous metals due to chemical reactivity at high temperatures; it’s here that Cubic Boron Nitride (CBN) tools often provide the complementary solution, offering the necessary stability for efficiently machining hardened steels and cast irons. PCD tools are vital in industries like automotive, aerospace, and woodworking, enabling higher precision, better surface finishes, and reduced machine downtime. Manufacturing PCD tools requires specialized techniques like diamond grinding, EDM, and laser ablation, and different PCD grades (based mainly on grain size) offer tailored properties for various tasks. Although the initial investment is higher, a careful evaluation of the total cost of ownership often reveals significant long-term savings in high-volume or challenging applications. Successful implementation requires attention to machine condition, proper handling, optimized cutting parameters, and potentially utilizing specialized resharpening services. When used correctly in the right applications, PCD tooling provides a powerful solution for boosting productivity and reducing manufacturing costs. Always consult with tooling suppliers for specific grade selection and application advice tailored to your unique needs.

References

- Polycrystalline Diamond (PCD) tools1 – Explore the comprehensive range of standard and custom PCD & PCBN tools from ZYDiamondTools.

- Sintering2 – ScienceDirect topic page explaining the sintering process in materials science.

- Differences between PCD and Carbide Tools3 – ZYDiamondTools blog post detailing the comparison between PCD and Carbide cutting tools.

- PCD vs. CBN distinction4 – ZYDiamondTools blog post detailing the comparison between PCD and CBN cutting tools.

- Different standard and custom tool formats5 – ZYDiamondTools blog post exploring various types of PCD cutting tools.

- Total Cost of Ownership (TCO)6 – ZYDiamondTools guide explaining the TCO concept and application for superhard tooling & abrasives.

ZY Superhard Tools Co., Ltd.

Do you have any needs for PCD tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Do you have any needs for PCD & CBN tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Do you have any needs for PCD & CBN tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Post Categories

Product Categories

About Company

Related Posts

Why Is Your Tooling Wearing Out Prematurely? A Machinist’s Guide to Key Causes & Proven Solutions

Facing premature tool wear? Learn the key causes like heat, vibration, & wrong parameters. Discover proven solutions from setup to

How Do You Select the Optimal PCD Tools for Scroll Compressor Machining?

Learn how to select the right PCD tools for scroll compressor machining. This guide covers the benefits over carbide, key

How Do You Choose the Right Cutting Tool for Your Mold Steel Machining?

Learn how to choose the right cutting tools for mold steel machining. This guide covers steel hardness, tool materials, coatings,

Machining Nickel-Based Superalloys: Tooling Selection and Case Studies

Learn to master machining nickel-based superalloys. This guide covers tooling selection (CBN, ceramics), parameter optimization, and real-world case studies. Read

Subscribe

Simply enter your email below and click “Subscribe” to stay connected with everything new and exciting.