-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

How to Choose the Right Superabrasive Bond for Glass Grinding

What is the primary factor in selecting the correct superabrasive bond for glass grinding1 applications?

Selection depends on aligning the bond matrix2 with the specific processing stage, machine rigidity, and glass substrate; metal bonds are essential for heavy stock removal and shape retention, resin bonds are required for fine finishing and self-sharpening, and bond hardness must be inversely matched to the glass hardness to prevent glazing or excessive wear.

Selecting Bonds by Machine Station and Processing Goal

The machine station dictates the bond choice based on mechanical rigidity and required processing speed; you must select wear-resistant bronze bonds for high-pressure straight-line edgers, while softer resin bonds are required for low-pressure CNC finishing stations to achieve the correct surface quality.

Bronze metal bonds for heavy stock removal on straight line edgers

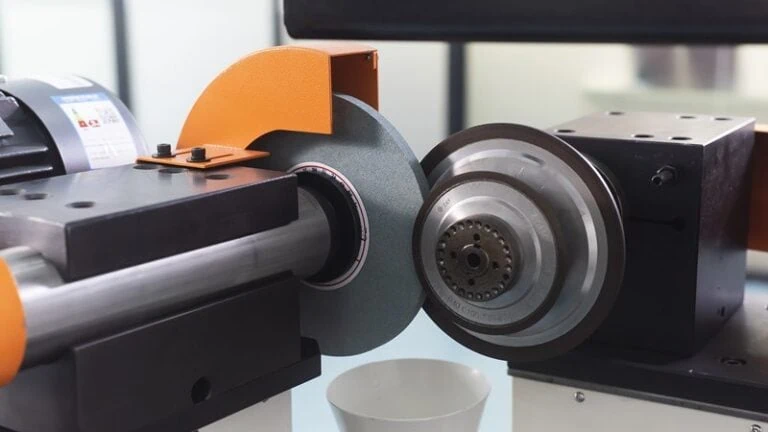

Straight-line edging machines are the heavy lifters of the glass industry. On these machines, the glass moves past stationary spindles at a constant speed. The first position (Pos 1) on these machines must remove the bulk of the raw glass edge to set the dimension.

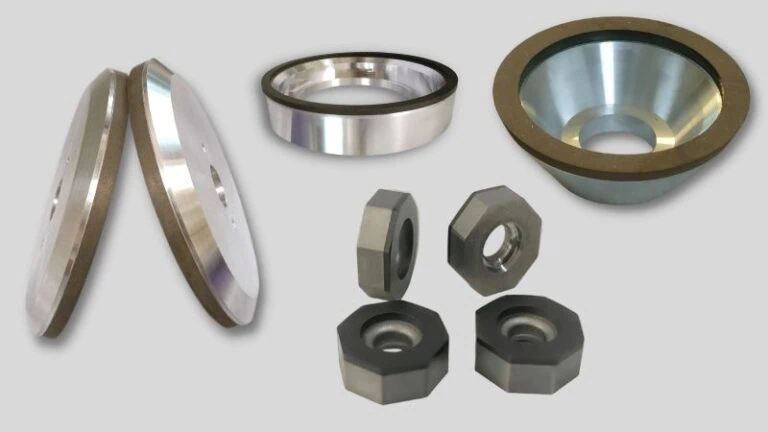

For this station, a bronze metal bond3 is the industry standard. Bronze bonds are hard and durable. They hold the diamond particles very tightly. This strong hold allows the wheel to grind away large amounts of glass without losing its shape.

Think of a bronze bond cup wheel like a roughing end mill in a metal machining center. Its primary job is to hog out material rapidly before any finishing work begins. It does not need to leave a pretty surface; it just needs to be aggressive and consistent.

Why Bronze Fits Straight-Line Machines:

- High Rigidity: These machines apply significant pressure. A softer bond would compress or deform, causing dimensional errors.

- Heat Tolerance: Removing 1mm to 3mm of glass generates high heat. Metal bonds conduct this heat away from the contact point better than resin.

- Form Retention: In a straight-line process, the wheel wears mostly in the center. Bronze resists developing a “groove” too quickly, reducing the frequency of mechanical adjustments.

Resin bonds for satin finishing on CNC work centers

CNC working centers operate differently than straight-line edgers. The spindle moves around the stationary glass, often tracing complex shapes. The mechanical arm of a CNC machine is generally less rigid than the heavy cast-iron base of a straight-line edger.

For the finishing passes on a CNC, you should use a resin bond4. Resin is softer and has a slight elasticity. This elasticity acts like a “finishing pass” tool, smoothing out the microscopic peaks and valleys left by the rough grinding step.

If you used a hard metal bond for the final pass on a CNC, the lack of “give” could cause vibration marks or chatter on the glass edge. Resin bonds yield slightly to the glass, creating a smooth, matte “satin” finish.

Key Operational Differences:

- Pressure Sensitivity: CNC spindles often use lower pressure. Resin bonds break down easier than metal, exposing sharp new diamonds without needing high force.

- Speed: Resin wheels typically run at higher RPMs to polish the surface rather than cut deep.

- Self-Sharpening: As the diamond gets dull, the resin wears away to reveal fresh sharp diamonds. This keeps the cut consistent without manual intervention.

Electroplated bonds for complex automotive glass profiles

Automotive glass often features non-standard edge profiles, such as asymmetric curves or specific safety rounds. Creating these shapes with a standard metal bond is difficult because dressing5 (reshaping) a sintered metal wheel to a complex profile takes a long time and wastes expensive abrasive.

Electroplated bonds6 are the solution here. In this process, a single layer of diamond is attached to a pre-machined steel core using nickel. The core is machined to the exact negative shape of the glass edge.

Advantages for Automotive Lines:

- Profile Accuracy: Since there is only one layer of diamond, the wheel does not lose its shape as it wears. It cuts the exact same profile from the first piece of glass to the last.

- No Dressing Required: You never need to true or dress these wheels. When the diamond layer is worn out, you simply replace the wheel or send it for replating.

Note: Since the diamond layer is thin, electroplated wheels have a shorter lifespan than sintered metal wheels. However, the elimination of downtime for dressing makes them profitable for high-volume automotive runs.

Hybrid bonds for high speed single pass operations

Modern double-edgers often need to grind and finish the glass in a single rapid pass to keep up with tempering furnaces. Using a pure metal bond might leave the edge too rough, but a pure resin bond might wear out too fast under the heavy load.

Hybrid bonds7 combine metal and resin powders (or ceramic and metal) in the matrix. They offer a middle ground for high-speed lines.

Hybrid Bond Characteristics:

| Feature | Hybrid Bond Behavior | Benefit for Production |

|---|---|---|

| Cutting Speed | Aggressive like metal | Allows faster conveyor feed rates |

| Finish Quality | Smooth like resin | Eliminates the need for a secondary polishing station |

| Wear Rate | Moderate | Lasts longer than resin, requires less dressing than metal |

These bonds are ideal for architectural glass lines running typically between 3 to 8 meters per minute.

Solving Production Pain Points Through Bond Modification

Modifying bond hardness and porosity directly solves production defects by altering the cutting dynamics; switching to softer resin bonds eliminates edge chipping by reducing grinding pressure, while increasing bond porosity prevents glass burns by enhancing coolant flow and debris evacuation.

Reducing edge chipping by switching to softer resin systems

Edge chipping often occurs when the grinding wheel is too hard for the specific application. A bond that holds the diamonds too tightly will not release them when they become dull. Instead of cutting, the dull diamonds hammer the glass surface. This impact causes small shell-shaped chips along the edge.

To fix this, you should switch to a softer resin bond. A soft resin bond wears away faster. This rapid wear constantly exposes new, sharp diamond particles. This process is called “self-sharpening.”

Think of this like using a fresh abrasive belt versus a glazed, worn-out one. The fresh belt cuts smoothly with little pressure. The worn belt requires you to push hard, which generates heat and damages the workpiece. A soft bond ensures the wheel always acts like the “fresh belt.”

Signs Your Bond is Too Hard:

- Visible chips on the bottom edge of the glass.

- Loud, high-pitched screaming noise during grinding.

- High machine amperage readings (motor load).

Please note that bond hardness scales (like R, N, or L) vary between manufacturers. Always verify the specific hardness grade with your supplier before ordering.

Preventing profile loss in pencil edging with wear resistant metal bonds

Pencil edging (creating a round “C” shape) presents a unique challenge compared to flat edging. The wheel must maintain a perfect concave radius. If the bond wears unevenly, the wheel loses its shape. The center of the wheel usually wears out first, causing the glass edge to become flat rather than round.

In this scenario, a soft resin bond is often a liability. It wears too quickly to hold the radius profile. The solution is to use a wear-resistant metal bond, typically bronze or iron-based.

Metal bonds have high “form holding” capability. They resist the abrasion of the glass edge and keep the diamond particles in place longer. This ensures the “C” profile remains consistent over thousands of meters of production.

Comparison of Bond Types for Pencil Edging:

| Feature | Soft Resin Bond | Wear-Resistant Metal Bond |

|---|---|---|

| Profile Retention | Low (Deforms quickly) | High (Maintains shape) |

| Dressing Frequency | High (Daily or hourly) | Low (Weekly or monthly) |

| Ideal Application | Final polishing only | Primary shaping and grinding |

| Defect Risk | Flat spots on edge | Potential for slow cutting |

Eliminating glass burns and loading by increasing bond porosity

Glass burns appear as a white haze or rough patches on the ground edge. This happens when the wheel generates too much friction heat. The primary cause is “loading.”

Loading occurs when fine glass dust (swarf) gets stuck in the spaces between the diamond particles. If the wheel face is smooth and clogged, coolant cannot reach the cutting zone. The wheel begins to rub rather than grind.

The solution is to increase the bond porosity. Porous bonds have an open structure with small air pockets.

How High Porosity Fixes Burns:

- Coolant Pockets: The pores hold water, bringing coolant directly to the contact point.

- Chip Evacuation: The pores provide a space for glass dust to escape, preventing clogging.

Imagine a saw blade cutting through material. If the gullets (spaces between teeth) are too small, the debris packs in tight, causing the blade to overheat and burn the material. Increasing bond porosity is exactly like making those gullets larger to clear the waste efficiently.

When to Request High Porosity:

- Processing thick glass (over 10mm) where heat buildup is high.

- Using laminated glass, where the plastic interlayer melts and clogs the wheel.

- Running machines with low coolant pressure.

Adapting Bond Hardness to Specific Glass Substrates

The hardness of the glass substrate dictates the necessary bond matrix; hard materials like quartz require softer bonds to promote self-sharpening, standard float glass pairs with harder bonds to maximize wheel life, and laminated glass requires specialized open-structure bonds to prevent the interlayer from clogging the wheel.

Soft bond matrices for hard quartz and borosilicate materials

There is a “Golden Rule” in the grinding industry that might seem backward at first: Process hard materials with a soft bond.

When you grind extremely hard glass, such as Borosilicate 3.38 (high-temperature glass) or Quartz9, the glass acts like a dressing stone. It dulls the diamond particles very quickly. If the bond holding the diamonds is too hard, it will hold onto those dull diamonds.

When dull diamonds rub against hard quartz, they generate friction instead of cutting. This leads to heat cracks and glazing.

To prevent this, you must use a soft bond matrix (often a soft bronze or specific resin). The soft bond sacrifices itself. As soon as a diamond becomes dull, the bond wears away to release it. This exposes a fresh, sharp diamond underneath.

Why Soft Bonds Work on Hard Glass:

- Continuous Cutting: It prevents the wheel from becoming “glazed” or smooth.

- Heat Reduction: By shedding dull diamonds, the wheel cuts cooler, protecting the heat-sensitive quartz.

Note: Borosilicate glass is significantly harder than standard window glass. Using a standard wheel on this material will likely result in immediate burning.

Harder bond formulations for standard soda lime and float glass

Soda lime glass10 is the standard material used for windows, doors, and furniture. It is softer and more abrasive than quartz. Because the glass is softer, the diamond particles stay sharp for a longer time.

Since the diamonds do not get dull quickly, you do not need the bond to wear away fast. Therefore, you should choose a harder bond formulation.

If you use a soft bond (meant for quartz) on standard float glass, the wheel will wear out prematurely. You will be grinding the glass effectively, but your tool costs will skyrocket because you are throwing away good diamonds before they are used up.

Economic Balance:

- Hard Bond + Soft Glass: Maximizes wheel life (Linear meters processed).

- Soft Bond + Soft Glass: Wastes tool life (High cost per meter).

Glass Type vs. Bond Hardness Selection Guide

| Glass Substrate | Hardness Level | Recommended Bond Hardness | Primary Goal |

|---|---|---|---|

| Quartz / Fused Silica | Very High | Soft | Prevent glazing and burning |

| Borosilicate (Pyrex) | High | Medium-Soft | Maintain sharp cutting edges |

| Soda Lime (Float) | Standard | Hard | Maximize tool longevity |

| Mirror Glass | Standard | Hard | Consistency and economy |

Specialized bond structures for processing laminated glass safety layers

Laminated glass presents a unique nightmare for grinding wheels: the plastic interlayer. This layer is usually PVB (Polyvinyl Butyral)11 or SGP (SentryGlas).

When you grind laminated glass, you are cutting two rigid sheets of glass and one soft, sticky layer of plastic simultaneously. Standard bonds struggle here. The plastic layer heats up, melts, and sticks to the wheel surface. This is called “loading.”

To handle this, manufacturers use specialized bond structures, often referred to as “sandwich” bonds or high-exposure structures.

Key Structural Features:

- Chip Clearance: The bond must be porous enough to allow the stringy plastic chips to escape, rather than packing into the wheel face.

- Sandwich Design: Some wheels for straight-line edgers use a “sandwich” construction. The top and bottom segments of the wheel use a harder bond to cut the glass, while the center segment uses a much softer, more porous bond specifically to cut the plastic interlayer.

If you attempt to grind laminated glass with a standard dense metal bond, the plastic will smear over the diamonds. The wheel will stop cutting the glass, and the resulting pressure will often shatter the laminate.

Conclusion

Choosing the right superabrasive bond is not a one-size-fits-all decision; it is a calculated balance between machine capability, quality requirements, and material properties. Whether you are using bronze bonds for heavy stock removal on straight-line edgers or soft resin bonds for heat-sensitive quartz, the goal remains the same: efficiency and quality.

By understanding the interaction between the bond matrix and the glass substrate, you can move beyond simply buying grinding wheels to engineering a more profitable production line.

References

- glass grinding1 – ZYDiamondTools industry page detailing tools specifically designed for glass and ceramic processing applications.

- bond matrix2 – ZYDiamondTools guide on selecting the correct bond matrix for optimal grinding performance.

- bronze metal bond3 – Product page for ZYDiamondTools’ bronze bond wheels, ideal for heavy stock removal.

- resin bond4 – ZYDiamondTools product category page featuring resin bond wheels for precision finishing.

- dressing5 – Practical how-to guide on dressing diamond grinding wheels.

- Electroplated bonds6 – ZYDiamondTools product category page for electroplated bond wheels.

- Hybrid bonds7 – ZYDiamondTools product category page for hybrid bond wheels used in high-speed operations.

- Borosilicate 3.38 – Wikipedia article explaining the properties and thermal resistance of borosilicate glass.

- Quartz9 – Wikipedia article defining the mineral composition and hardness properties of Quartz.

- Soda lime glass10 – Wikipedia article explaining the composition and common uses of standard soda-lime glass.

- PVB (Polyvinyl Butyral)11 – Wikipedia article on PVB resin used for applications that require strong binding and transparency.