-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

Honing vs. Internal Grinding: Which Precision Finishing Process Is Right for Your Application?

- Grinding Wheels Knowledge, Industry Knowledge, Knowledge

- -2025-06-24

- - byKevin Ray

When it comes to achieving the perfect internal finish on a critical component, what is the real difference between honing and internal grinding, and how do you choose the right one?

The core difference is that honing is a low-speed, multi-point finishing process that perfects a bore’s shape and creates a functional cross-hatch surface, while internal grinding is a high-speed, single-point process that establishes a bore’s precise size and location. The right choice depends on your primary goal: use grinding for significant stock removal and positional accuracy, and use honing for geometric correction and creating an oil-retaining surface.

Table of Contents

ToggleHow Do Their Machining Mechanics Fundamentally Differ?

So, what truly sets the fundamental mechanics of honing and internal grinding apart?

At its core, the difference lies in the tool’s design, its movement, and how it contacts the workpiece. Honing uses multiple abrasive points with low-speed, combined rotational and back-and-forth motions over a large area. In contrast, internal grinding uses a single, high-speed rotating wheel that makes contact on a very small line, concentrating its force.

Let’s break down these mechanical distinctions one by one.

The Tool: Multi-Point Abrasives vs. a Single-Point Wheel

The most obvious difference begins with the tools themselves. Imagine the task is to smooth the inside of a metal pipe. You have two very different tools to choose from.

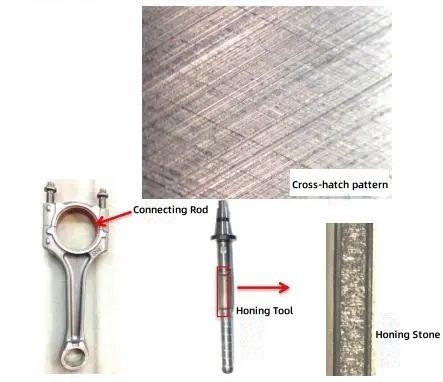

The honing tool, or hone, is like a sophisticated bottle brush. Instead of bristles, it has several rectangular “stones” or “sticks” made of abrasive material1. These stones are mounted on a tool body, called a mandrel, that can expand. When the hone enters the workpiece bore, it pushes these abrasive stones outwards, forcing them to press against the entire inner wall simultaneously. This is a multi-point abrasive system, where the workload is shared across several cutting surfaces.

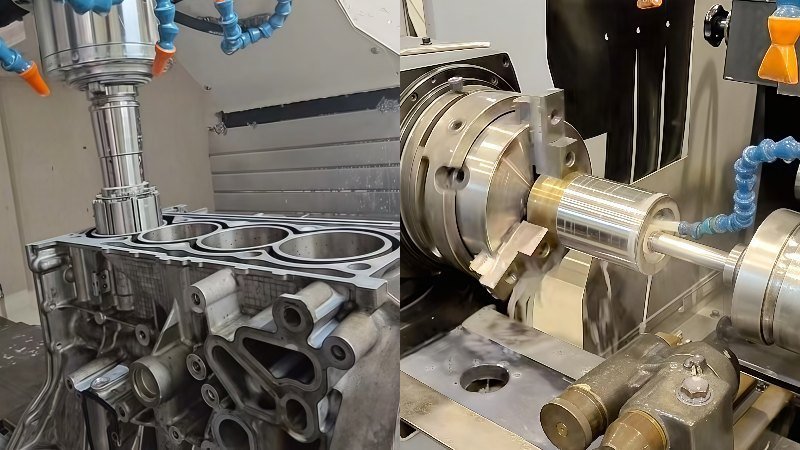

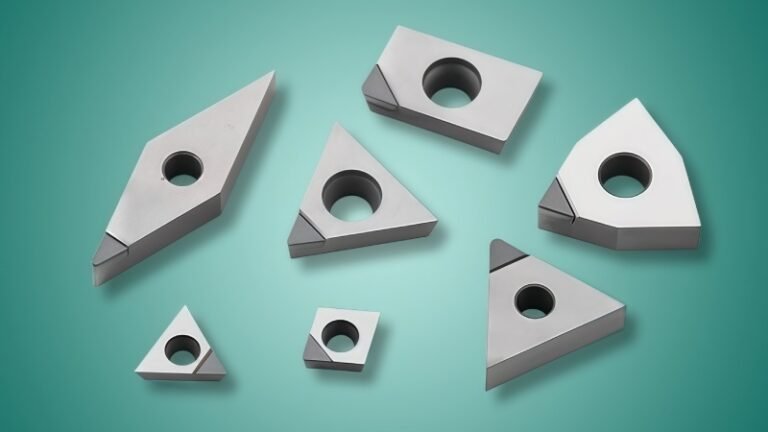

On the other hand, the tool for internal grinding is a single, solid abrasive wheel2. Think of it as a small, hard grinding stone mounted on the end of a spindle. This wheel is a single-point abrasive system. Unlike the hone, it does not expand. All the cutting action is performed by the outer edge of this one rapidly spinning wheel.

| Feature | Honing Tool | Internal Grinding Wheel |

|---|---|---|

| Tool Type | Expanding mandrel with multiple abrasive “stones” | Single, solid bonded abrasive wheel |

| Abrasive Points | Multi-point contact | Single-point (line) contact |

| Analogy | A bottle brush with sandpaper on its bristles | A small, spinning sharpening stone on a stick |

The Motion: Low-Speed Reciprocation vs. High-Speed Rotation

How these tools move is also fundamentally different, directly impacting the process.

Honing is characterized by a low-speed combination movement. The honing tool rotates relatively slowly (often just a few hundred RPM) while simultaneously moving back and forth along the length of the bore. This combined rotational and reciprocating motion is key to the results it produces. It’s a gentle, controlled action designed for fine-tuning.

Internal grinding, in stark contrast, is all about high-speed rotation. The small grinding wheel spins at incredibly high velocities, often ranging from 20,000 to over 60,000 RPM. While the wheel is spinning, the workpiece itself is also rotating, usually in the opposite direction at a much slower speed. The primary cutting action comes from the immense surface speed of the tiny grinding wheel.

For context, this extreme speed is necessary to allow the small wheel to effectively cut hard materials. Keep in mind that specific operational speeds for both processes are highly dependent on the machine, material, and desired outcome, so you should always consult your equipment supplier for precise operational ranges.

The Physics: Area Contact vs. Line Contact

This brings us to the physics of how force is applied. What is actually happening where the tool meets the metal?

In honing, because the multiple abrasive stones are pressed against the inner wall, the cutting force is distributed over a very large surface area. Think about sanding a piece of wood with a wide sanding block. The pressure at any single point on the surface is relatively low because it’s spread out. This makes honing a low-pressure finishing process.

In internal grinding, the entire cutting force is concentrated on the very small section where the spinning wheel touches the workpiece—a thin line of contact. Imagine trying to draw on that same piece of wood, but now with the very fine tip of a sharp, hard pencil. All your force is focused on that tiny point. This makes grinding a high-pressure machining process.

This single distinction—area contact versus line contact—is the root cause for the differences in heat, material removal, and ultimately, the final surface characteristics.

The Impact: Heat Generation and Material Removal Rate

The differences in tool, motion, and physics have two immediate and critical consequences: heat and the speed of material removal.

Heat Generation

Have you ever noticed how a drill bit gets hot when you use it? That’s energy turning into heat. In machining, controlling heat is critical.

- Internal Grinding: Because it concentrates so much energy onto a tiny point, it generates intense, localized heat. This often requires aggressive cooling systems to prevent thermal damage to the workpiece, altering its metallurgical properties or causing warping.

- Honing: As a low-speed, low-pressure process that spreads its work over a large area, honing generates very little heat. It is considered a “cold” machining process, which minimizes the risk of thermal damage to the part.

Material Removal Rate (MRR)

The Material Removal Rate simply means how quickly the process can remove metal.

- Internal Grinding: Thanks to its high speed and concentrated force, grinding has a high MRR. It can quickly and efficiently remove a significant amount of material, making it ideal for taking a rough-machined bore and bringing it close to its final size.

- Honing: With its gentle, low-pressure action, honing has a very low MRR. It’s not designed to remove large amounts of stock. Instead, its purpose is to shave off the last few thousandths or even millionths of an inch to perfect the geometry and create a specific surface texture. It is a true finishing process, not a primary stock removal method.

What Are the Key Differences in the Final Workpiece?

Now that we understand how the machines work, how do these different mechanics actually affect the finished part you can see and measure?

The primary difference in the final workpiece lies in surface function and geometric capability. Honing creates a unique, functional cross-hatch surface texture and is unmatched at correcting a bore’s roundness and straightness. Conversely, internal grinding excels at achieving a precise bore diameter and establishing the bore’s exact location relative to other part features.

These outcomes determine which process is chosen for a specific engineering application. Let’s examine these differences in detail.

Surface Finish: The Functional Cross-Hatch vs. a Unidirectional Pattern

When engineers talk about “surface finish,” they aren’t just talking about how smooth a part is. They are often more interested in the microscopic texture or pattern left on the surface, as this pattern can serve a critical purpose.

The Honing Cross-Hatch: A Functional Surface

The most recognizable result of honing3 is the distinct cross-hatch pattern it leaves on the inner surface of a bore.

This pattern of fine, crisscrossing lines is created by the tool’s combined rotation and back-and-forth motion. But why is this pattern so important? It’s an engineered feature designed to hold lubrication. The tiny valleys in the cross-hatch act as microscopic reservoirs for oil.

Industry Example: Engine Cylinders

In an automotive engine, this is not just a benefit; it is a requirement. The cross-hatch pattern on the cylinder walls holds a thin film of oil, which is essential for lubricating the piston rings as they move up and down thousands of times per minute. This reduces friction, minimizes wear, and is critical for the engine’s long-term health and performance. Without it, the engine would fail very quickly.

The angle and depth of this pattern are tightly controlled specifications. While these can be adjusted, it’s crucial to adhere to the parameters defined by the engineering drawings or to verify them with your supplier to ensure proper component function.

The Grinding Unidirectional Pattern

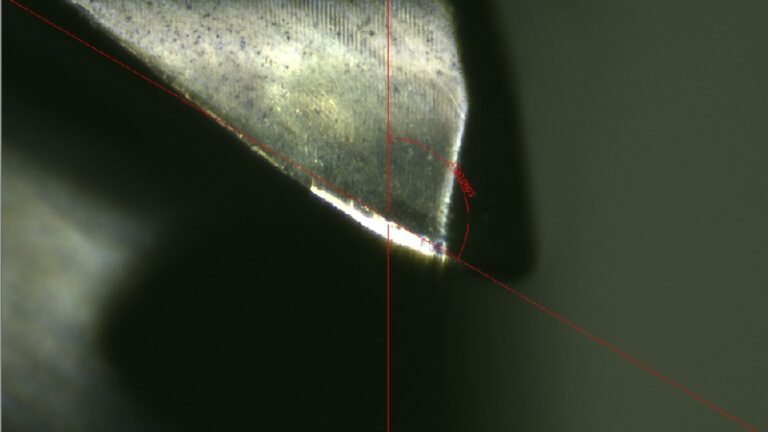

Internal grinding produces a very different surface. Because the cutting action comes from a wheel spinning in one primary direction, it creates a unidirectional or spiral pattern. The surface can be made exceptionally smooth (achieving a very low Ra, or Roughness average4 value), but it lacks the oil-retaining valleys of a honed finish. For many applications, this simple, smooth surface is perfectly acceptable and desired.

| Feature | Honing Finish | Internal Grinding Finish |

|---|---|---|

| Pattern | Cross-hatch (crisscrossing lines) | Unidirectional (spiral lines) |

| Primary Function | Holds lubrication, reduces friction | Provides a smooth, low-friction surface |

| Key Advantage | Superior oil retention for sliding parts | Can achieve extremely low surface roughness |

| Prime Example | Engine Cylinder Walls | Bearing Races |

Geometric Accuracy: Correcting Bore Geometry vs. Establishing Position

In precision manufacturing, “accuracy” is not a single concept. It involves both the shape of a feature (its geometry) and the location of that feature (its position). Honing and grinding are masters of two different domains of accuracy.

Honing’s Strength: Correcting Bore Geometry

Think of honing as a process that perfects an existing hole. A honing tool is inherently self-aligning; it follows the general path of the bore that is already there. Because its abrasive stones push outward with equal force, they naturally scrub away the “high spots” inside the bore.

This makes honing exceptionally good at fixing geometric errors, such as:

- Roundness: It can take a slightly oval or egg-shaped hole and make it perfectly round.

- Cylindricity: It can correct taper, which is when a hole is wider at one end than the other.

- Straightness: In long bores, it can fix minor “rainbow” or “banana” shaped curves.

However, it’s critical to understand honing’s limitation: it cannot change a hole’s location. If a hole was drilled off-center, honing will simply produce a perfectly round, straight hole that is still off-center.

Grinding’s Strength: Establishing Position

This is where internal grinding shines. In a grinding operation, the workpiece is held rigidly in a precision chuck, and the grinding spindle’s location is controlled by the machine’s precise axes.

This allows grinding to not only produce a hole of a specific size but to establish the true position of that hole relative to other datums on the part. For instance, it can make the inside bore perfectly concentric (perfectly centered) with the outside diameter of a part. If a hole was drilled slightly off-center, a grinder can actually move its location to the correct coordinates.

Industry Example: Precision Bearing Races

For a ball bearing to spin smoothly at high speeds without vibration, the inner and outer grooves (raceways) must be perfectly round and perfectly concentric with each other. Internal grinding is the only process that can reliably establish this precise positional relationship while also creating the required size and smooth finish.

Typical Industry Applications and Use Cases

Based on these distinct outcomes, the choice between honing and grinding becomes clear when looking at real-world parts.

Choose Honing For:

- Engine & Compressor Cylinders: The functional cross-hatch for oil retention is the primary driver.

- Hydraulic Valve Spools & Cylinders: Requires a great surface seal, low friction, and excellent roundness for preventing leaks and ensuring smooth operation.

- Firearm Barrels: Needs exceptional straightness and a consistent internal finish for projectile accuracy.

- Connecting Rods & Gear Bores: Where correcting the roundness and straightness of the bore is more critical than changing its location.

Choose Internal Grinding For:

- Ball & Roller Bearing Races: When the bore’s diameter and its concentricity (position) to other features are the most critical requirements.

- Fuel Injector Bodies & Nozzles: These components demand some of the tightest dimensional and positional tolerances in manufacturing.

- High-Performance Gear Bores: To ensure the gear’s center of rotation is perfectly aligned with the pitch circle of the teeth for smooth, quiet power transmission.

- Jig Bushings: The internal diameter must be perfectly located to accurately guide drills or reamers in subsequent operations.

How Do You Decide Which Process to Use?

So, how do you make the final call between honing and internal grinding for your specific part?

The decision hinges on three primary factors: the amount of material to be removed, the required surface texture and its function, and the specific geometric tolerances needed. As a general rule, use internal grinding for significant stock removal and establishing precise positioning, and choose honing for correcting a bore’s shape and creating a functional, oil-retaining surface.

To make the right choice, you can walk through the following decision-making steps.

Decision Factor 1: The Amount of Stock to Be Removed

The first and most straightforward question to ask is: how much material needs to be taken out of the hole?

This is a simple numbers game. If the hole is far from its final size, you need a process with a high material removal rate.

- Choose Internal Grinding if you need to remove a significant amount of stock. Think of it as the heavy-lifting process. Typically, grinding is used when the stock to be removed is more than about 0.005 inches (or roughly 0.13 mm). It efficiently brings the part close to its final dimensions.

- Choose Honing if you are only removing a tiny amount of material for the final touch. Honing is a true finishing process, usually removing less than 0.005 inches, and often as little as 0.0005 inches (about 0.013 mm). It is not designed or cost-effective for heavy stock removal.

It’s important to remember that these stock removal values are general guidelines. The exact capabilities can vary based on the specific material, machine, and tooling, so it’s always wise to confirm details with your machining partner.

Decision Factor 2: The Required Surface Texture and Functionality

Next, consider the purpose of the finished surface. What does the surface need to do?

The answer to this question can often make the decision for you. The key question is: does the part require a surface that actively retains oil?

- If YES, you must choose Honing. Only honing can produce the signature cross-hatch pattern that is specifically engineered to hold lubrication for sliding components. As we discussed, this is non-negotiable for parts like engine cylinders or hydraulic valves.

- If NO, then either process could be suitable. If the only requirement is a smooth, clean surface without any specific oil-retaining function, then internal grinding is a perfectly valid option. At this point, the other factors, like geometric tolerances, become the deciding elements.

Decision Factor 3: The Specific Geometric Tolerances

Finally, you need to look at the engineering drawing and understand what type of accuracy is most critical. Is it the perfection of the hole’s shape or the perfection of its location?

When to Prioritize Positional Accuracy (Choose Grinding)

If the engineering drawing has very tight tolerances for concentricity5, perpendicularity, or true position, your choice must be internal grinding. These callouts mean the bore’s location relative to another feature is critical. Since honing follows the existing path of a hole, it cannot correct positional errors. Grinding is the only one of the two processes that can establish or correct a hole’s location.

When to Prioritize Geometric Shape (Choose Honing)

If the drawing has very tight tolerances for roundness, cylindricity6 (taper), or straightness, your best choice is honing. Honing is unmatched in its ability to take an existing, correctly positioned hole and perfect its shape, making it incredibly round and straight along its entire length.

Case Study: A High-Performance Gear

Imagine a gear where the central hole has been drilled and heat-treated. The heat treatment may have slightly distorted the hole, making it a bit oval. The hole’s location is already correct, but its shape is not.

- Wrong Choice: Using an internal grinder might struggle to perfectly average out the ovality without affecting the location.

- Right Choice: Using a hone will quickly scrub out the high spots of the oval shape, resulting in a perfectly round bore without changing its already correct location. This is the ideal finishing step.

A Quick-Reference Decision Chart

To simplify everything, here is a chart to guide your decision-making process.

| Decision Factor | Choose INTERNAL GRINDING If… | Choose HONING If… |

|---|---|---|

| Stock to be Removed | High (e.g., > 0.005″ / 0.13 mm) | Low (e.g., < 0.005″ / 0.13 mm) |

| Surface Requirement | You need a simple, smooth finish with no special texture. | You need a functional cross-hatch pattern to retain oil. |

| Critical Geometric Tolerance | The location of the bore is most important (e.g., concentricity, true position). | The shape of the bore is most important (e.g., roundness, straightness, cylindricity). |

Conclusion

Ultimately, honing and internal grinding are not direct competitors but rather two distinct and highly specialized tools in the precision machinist’s toolkit. They solve different problems and achieve different outcomes. Internal grinding is a formative process, used to rapidly establish the precise size and location of a bore. Honing is a final finishing process, used to perfect the geometry of that bore and impart a superior, functional surface. By evaluating your specific requirements for stock removal, surface function, and geometric accuracy, you can confidently select the ideal process to ensure your components meet their exact engineering specifications.

References

- abrasive material1 – ZYDiamondTools product page for diamond oil honing stones, a key component in honing tools.

- solid abrasive wheel2 – ZYDiamondTools product page for electroplated diamond mounted points, which are often used for internal grinding applications.

- honing3 – A detailed guide from ZYDiamondTools explaining the honing process and how it achieves a perfect surface finish.

- Ra, or Roughness average4 – Wikipedia’s comprehensive page on surface roughness, defining key parameters like Ra and their importance in engineering.

- concentricity5 – A practical guide from GD&T Basics explaining the concept of concentricity with clear diagrams.

- cylindricity6 – A practical guide from GD&T Basics explaining the GD&T concept of cylindricity, a geometric error that honing excels at correcting.

ZY Superhard Tools Co., Ltd.

Do you have any needs for PCD tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Do you have any needs for PCD & CBN tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Do you have any needs for PCD & CBN tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Post Categories

Product Categories

About Company

Related Posts

Which Turning Insert Shape Should You Choose?

Master turning insert selection. Our guide covers choosing the right shape for your job, decoding ISO codes, and selecting the

How Do You Solve Vibration, Chip Control, and Surface Finish Issues in PCD Grooving?

Solve common PCD grooving problems. This guide details how to fix vibration, improve chip evacuation, and achieve a flawless sidewall

Why Is Your Tooling Wearing Out Prematurely? A Machinist’s Guide to Key Causes & Proven Solutions

Facing premature tool wear? Learn the key causes like heat, vibration, & wrong parameters. Discover proven solutions from setup to

How Do You Select the Optimal PCD Tools for Scroll Compressor Machining?

Learn how to select the right PCD tools for scroll compressor machining. This guide covers the benefits over carbide, key

Subscribe

Simply enter your email below and click “Subscribe” to stay connected with everything new and exciting.